JOHNSON CONTROLS

15

FORM 102.20-N1

ISSUE DATE: 7/06/2016

2

SECTION 2 - PRODUCT DESCRIPTION

Ventilation System

The purpose of a ventilation system is to remove air

that is substandard to creature comfort or a process,

and replace it with suitable air. Depending on the ap-

plication, the system will operate at various specified

rates, volumes, and conditions. A ventilation system

may employ an AHU with a supply fan working in

conjunction with a remote exhaust fan(s). A more ef-

fective method would employ a supply fan and an ex-

haust fan in the AHU.

Economizer System (Typical)

The economizer system typically consists of:

• Outdoor and return air dampers

• Damper actuator

• Enthalpy control

• Minimum outdoor air adjustment

• Exhaust air control

The economizer system provides the first stage of cool-

ing whenever the outdoor air is cool and dry enough to

satisfy the internal cooling demand. The outdoor and

the return air dampers are operated by individual ac-

tuators. As the outdoor air dampers are opened by the

damper actuator, the return air dampers are closed.

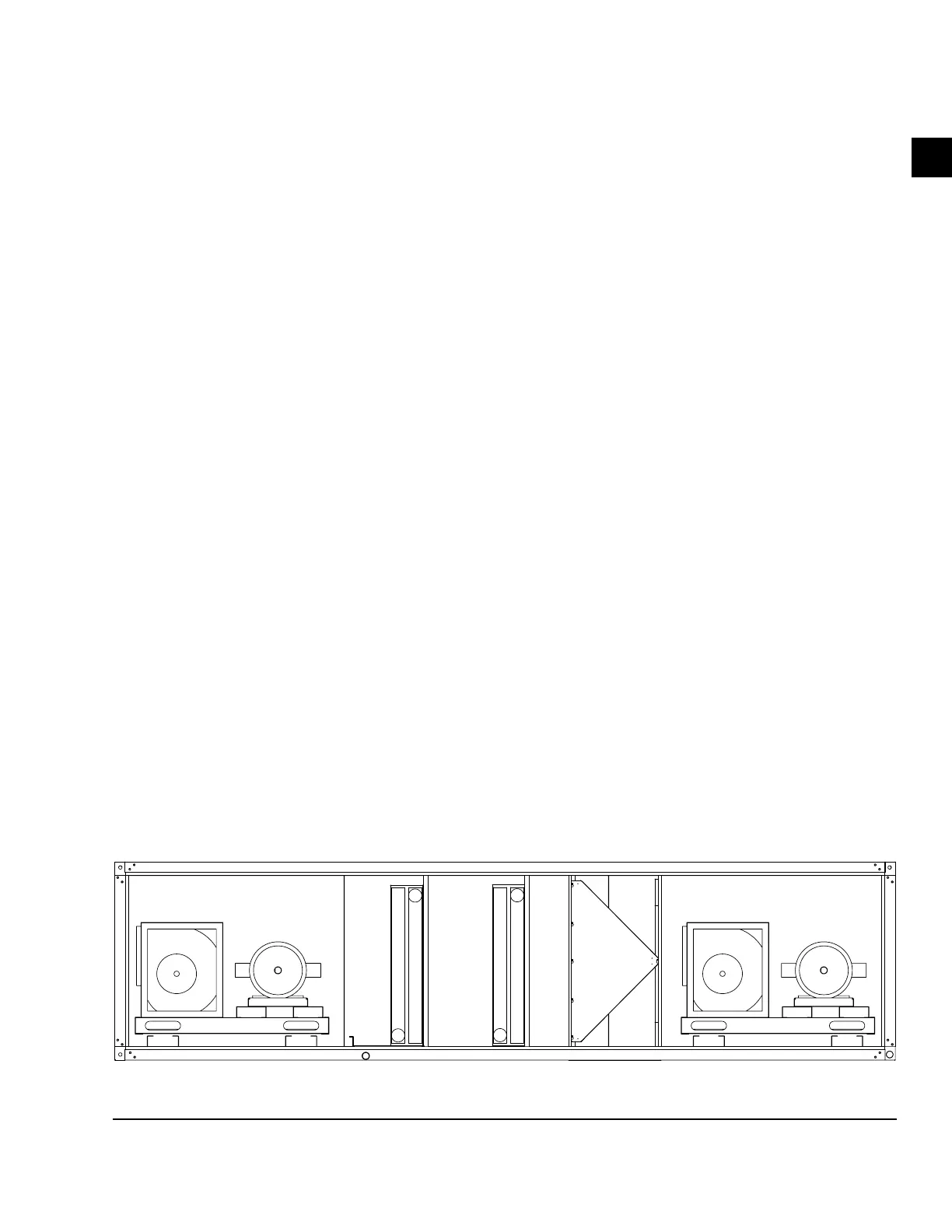

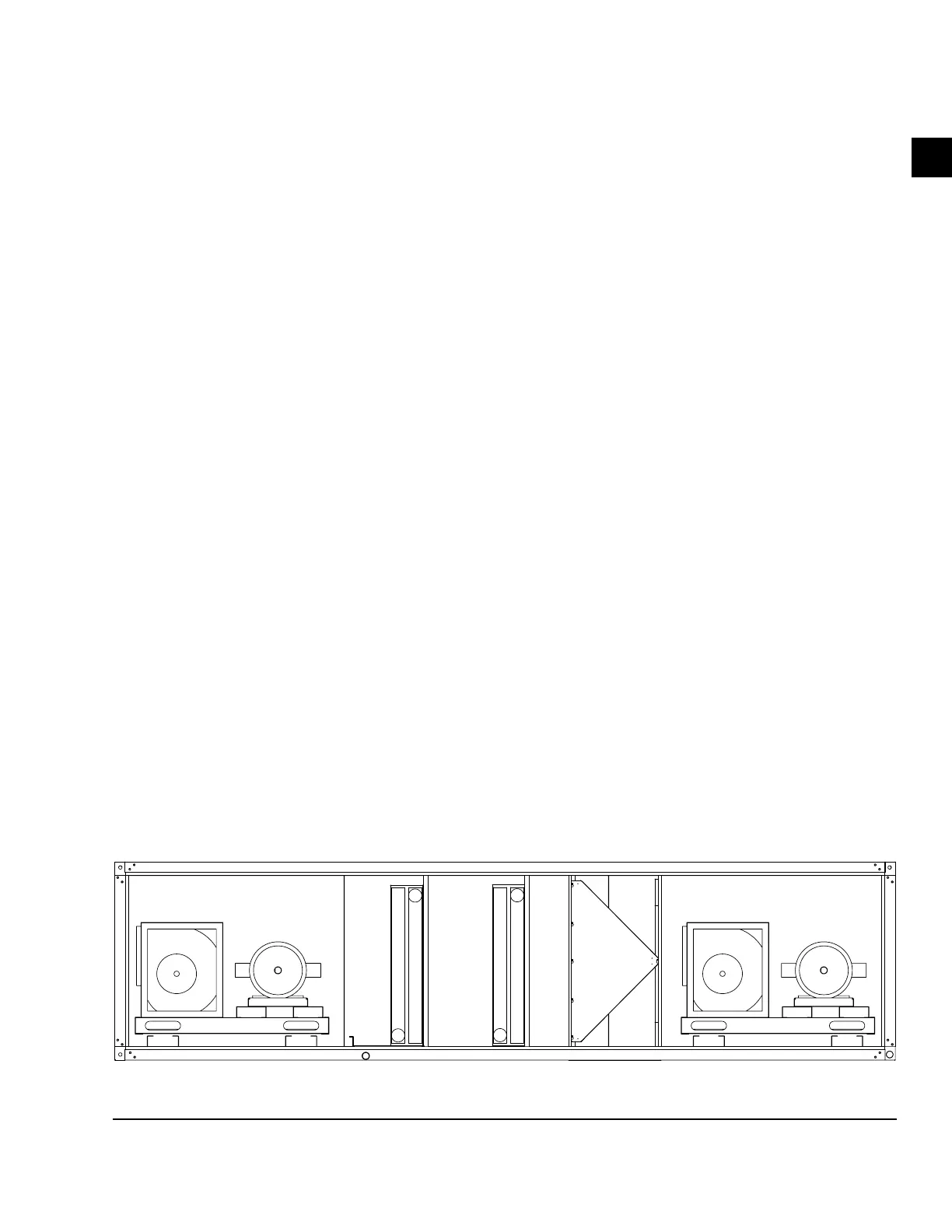

The AHU features segmented construction, and is fac-

tory assembled. Segment arrangements will vary to suit

the job application as shown in Figure 1 on page 15.

Features of the AHU include:

• Heavy gauge galvanized steel is used on the exte-

rior and interior of the AHU.

• Access doors are provided for accessibility to the

various sections.

• Removable access panels are standard in lieu of

doors on commercial performance AHUs.

• Panels and doors are constructed with double

walls.

• Panels, doors, and structural frame are insulated

with spray-injected foam.

TYPICAL SOLUTION OPERATION

The operation of the AHU is divided into four systems:

1. Ventilation

2. Economizer (Return Air/Mixing Box Section)

3. Heating

4. Cooling

5. Cleaning

LD13764

FIGURE 1 - CUTAWAY OF SOLUTION XT

SHOWING SEGMENTED CONSTRUCTION

Loading...

Loading...