JOHNSON CONTROLS

88

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

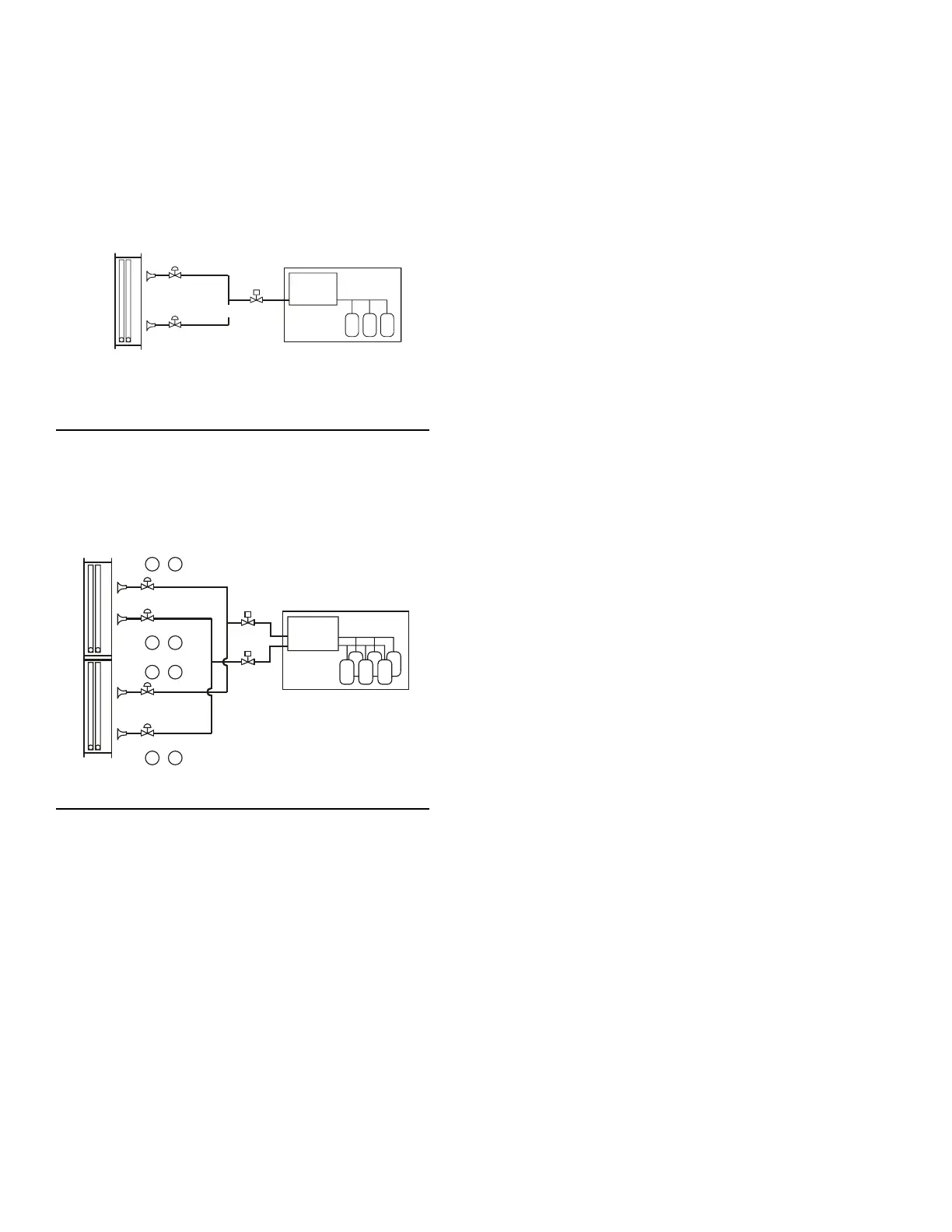

When the condensing AHU has three compressors per

circuit, use two coil circuits for each refrigerant circuit

as shown in Figure 136 on page 88. Each coil circuit

must have a dedicated TXV and distributor to handle

one coil circuit, and the LLSV should be sized to han-

dle the full capacity of the refrigerant circuit. Connect

the HGPB line to all distributors in the coil circuit.

FIGURE 136 - THREE COMPRESSOR UNIT

LD09151

Compressor #1

TXV

Compressor #3

Feeds Both Circuits

TXV

Compressor #2

LLSV

Condensing Unit

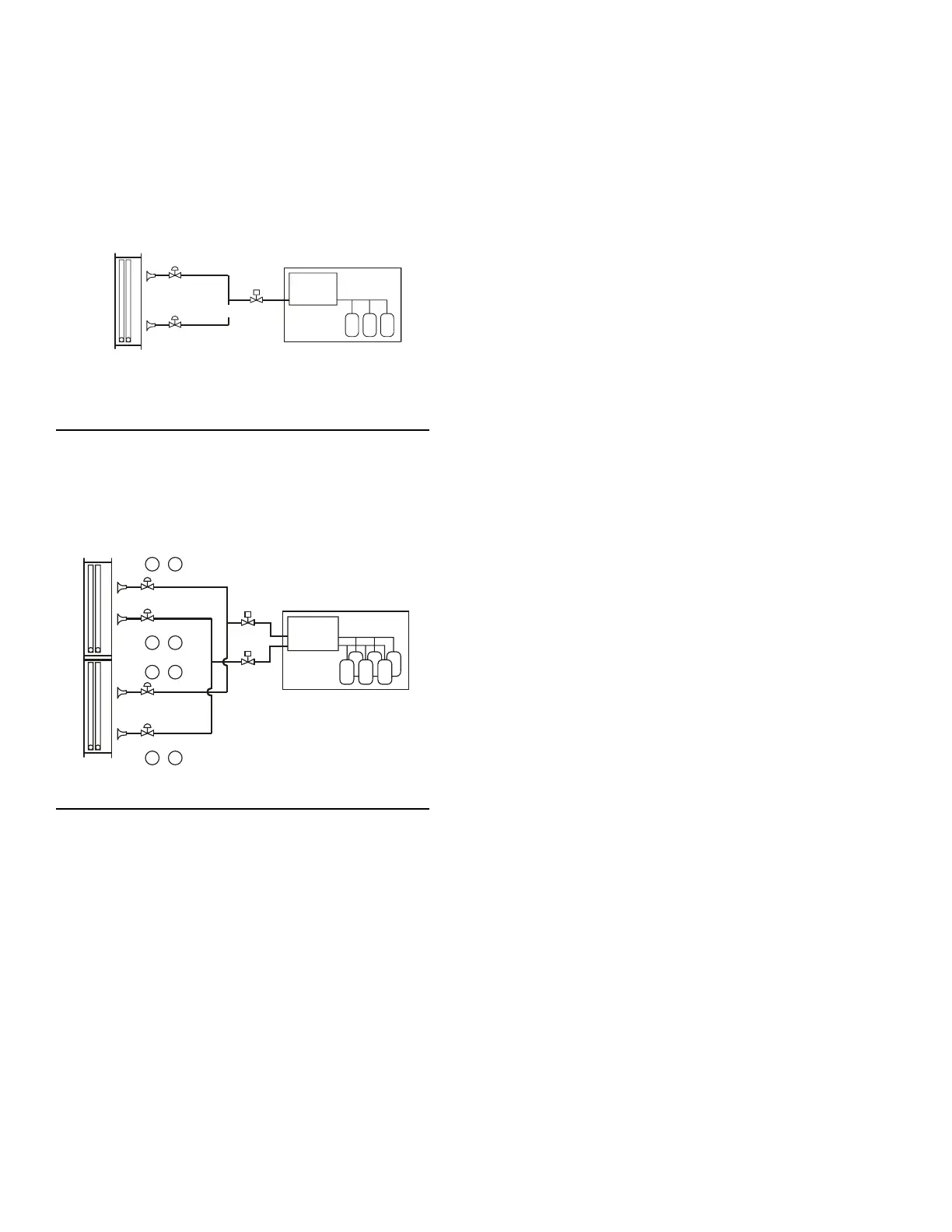

In a stacked coil with four coil circuits piped to a con-

denser with six compressors, the coil circuits would be

face split and interlaced with two interlaced circuits on

the lower coil section and two on the upper section as

shown in Figure 137 on page 88.

1-3

4-6

4-6

1-3

FIGURE 137 - SIX COMPRESSOR UNIT

LD09153

Comp

TXV1

TXV3

TXV2

TXV4

Comp

Comp

Comp

DX Coils

LLSV1

LLSV2

Condensing Unit

When sizing TXVs, size the TXV for the refrigerant

circuit tonnage divided by the number of DX coil liq-

uid distributors, which should be equal to or smaller

than the calculated value.

The first three compressors would be tied into LLSV1,

TXV1 and TXV2, which would provide full face con-

trol of the coil at the lowest cooling loads. Both dis-

tributors on each coil circuit would include auxiliary

side connectors for HGBP.

The second set of three compressors would be tied into

LLSV2, TXV3 and TXV4 to maintain full-face control

at higher loads. Refer to Guidelines for Proper Appli-

cation Piping and Guidelines for Split Systems (Form

050.40-ES3) for compressor staging solutions.

Advantages of Multiple Control Stages

The more control stages used, the more precise the con-

trol of the air temperature will be. Smaller incremental

changes in capacity will result in a more consistent DX

coil leaving air temperature, which will eliminate tem-

perature swings in the conditioned space and improve

the comfort level. But more importantly, a consistent

space temperature is crucial to many process applica-

tions.

The smaller changes in capacity that result from us-

ing a greater number of control stages will also extend

equipment life. The most important thing to remember

is to maintain full-face control of the coil at all cooling

loads. When row split coils are used, make sure that

the first LLSV is energized with the last coil circuit in

the leaving air stream, which is always the last one de-

energized too.

MAINTAINING ADEQUATE AIRFLOW

An electrical interlock between the AHU and the con-

denser must be included for permissive run of the

condenser. In addition, a differential pressure switch

mounted across the supply fan must always be includ-

ed to ensure airflow across the coil before the condens-

ing AHU is energized. The condenser must never be

operated unless the AHU fan is operating and air is

flowing across the active coil. Insufficient airflow will

result in liquid refrigerant returning to the condensing

AHU, which could damage the compressors by liquid

slugging or washing oil from the bearing surfaces.

In variable volume systems, the minimum acceptable

airflow for fixed speed or variable air volume (VAV)

systems is 350 FPM face velocity across each DX coil,

as applied to split DX systems. Make sure that the TXV

does not overfeed, because it could cause compressor

failure.

The air velocity flowing through chilled water and di-

rect expansion coils must not exceed specific recom-

mended values to prevent water carryover.

Loading...

Loading...