JOHNSON CONTROLS

24

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

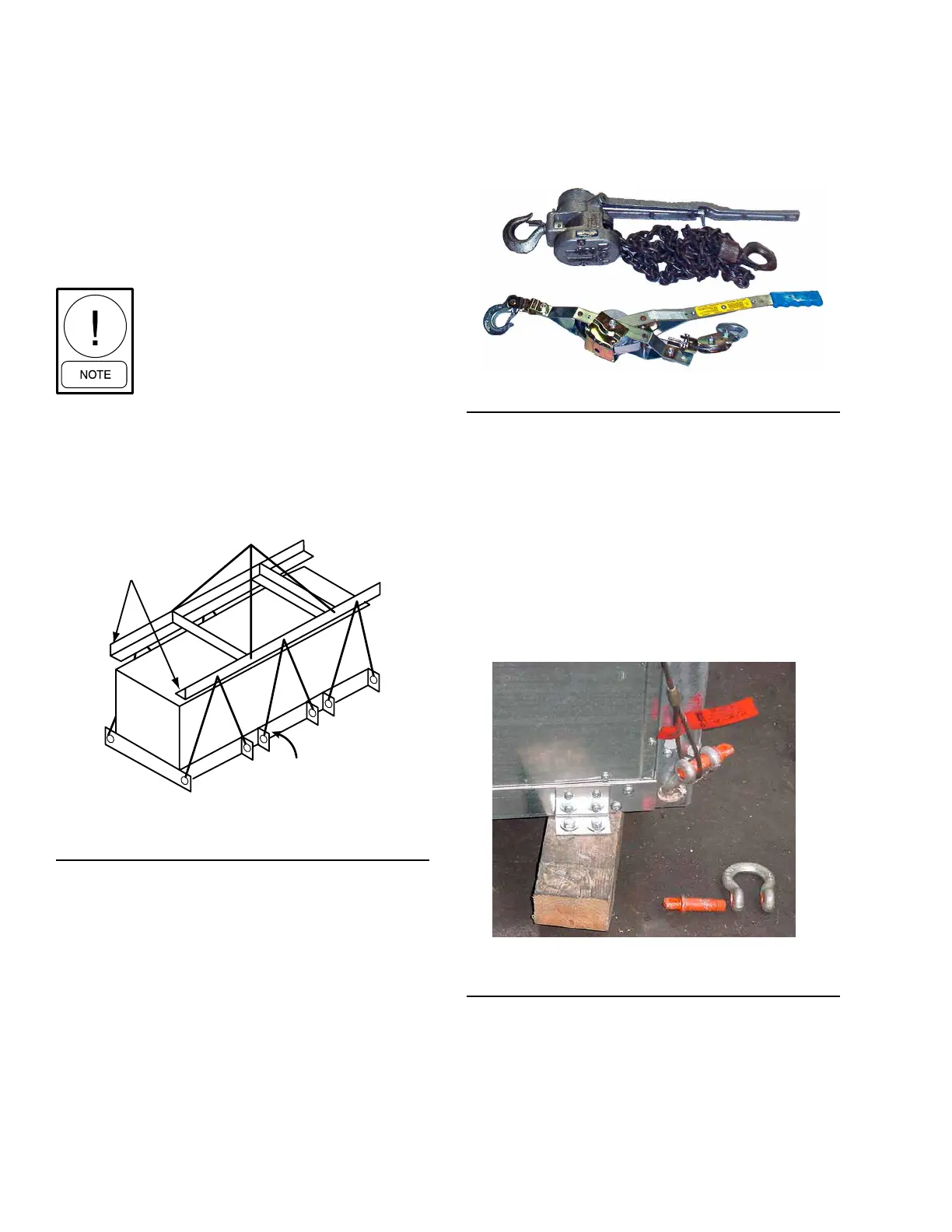

COME-A-LONGS (POWER PULLS)

If the AHU has multiple sections, use come-a-longs

(power pulls) as shown in Figure 11 on page 24 to

pull the sections or skids together.

LD09613a

FIGURE 11 - TYPICAL COME-A-LONGS

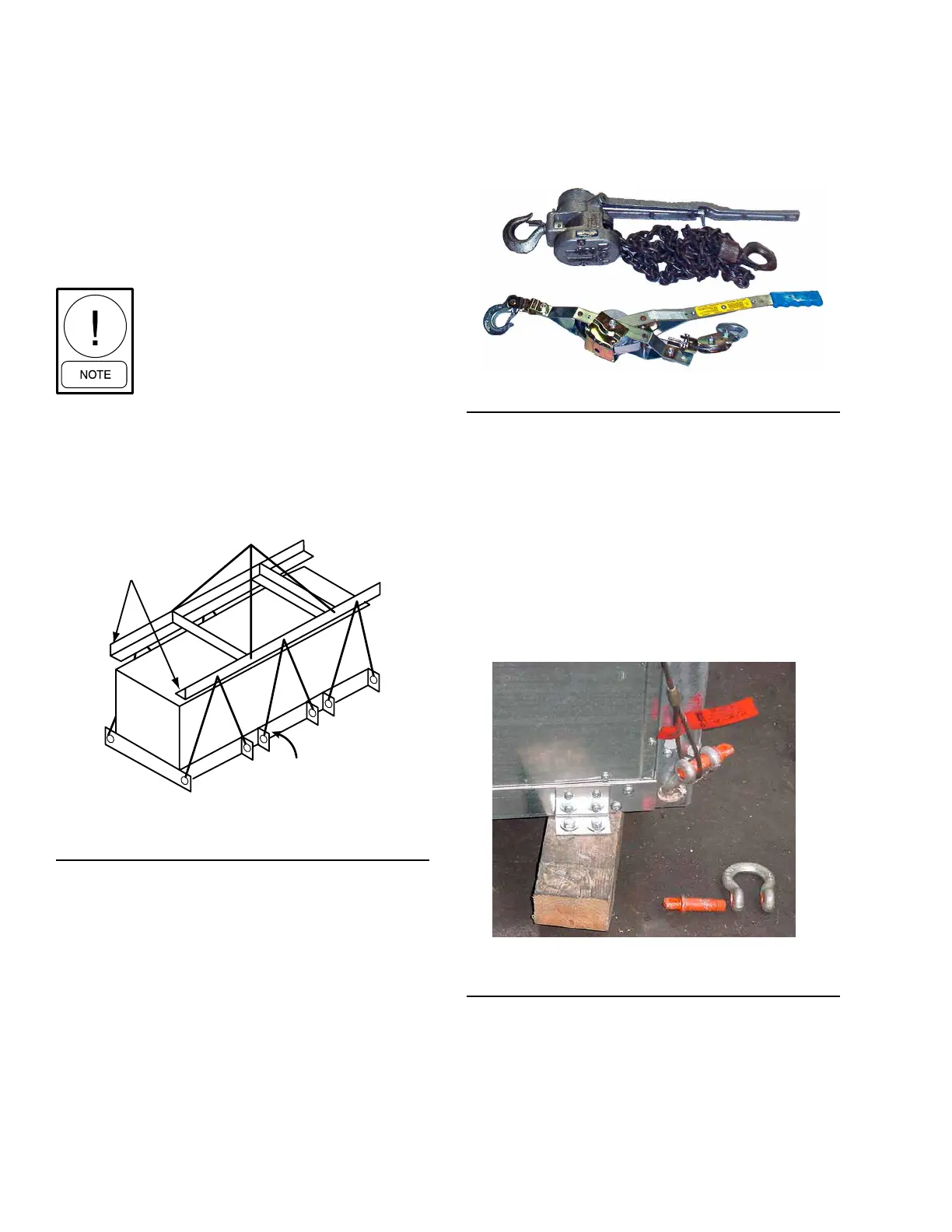

PROPER LIFTING WITH SHACKLES

Shackles are fastened to a sling or chain, which is used

to lift and lower the sections in a tiered AHU. Refer to

the following figures for proper lifting:

• Figure 12 on page 24 for proper lifting with a

hook and shackle at the corners.

• Figure 13 on page 25 for proper lifting with a

hook and shackle at the lifting lugs.

• Figure 14 on page 25 for lifting with a base rail.

LD13767

FIGURE 12 - PROPER LIFTING WITH SHACKLE

WITH CORNER CONNECTOR CORNERS

An experienced and reliable rigger must handle the un-

loading and final placement of the AHU, and must be

advised of the following:

• AHU contains internal components and should be

handled in an upright position.

• Care must be exercised to avoid twisting the

equipment structure.

• Prevent unnecessary jarring or rough handling.

Proper rigging and handling of the

equipment is mandatory during unload-

ing and setting it into position to prevent

voiding the warranty.

Use the proper spreader bars and hoisting lines when

rigging to prevent damage to the AHU casing.

When lifting long AHUs, a special system must be

used to insure a minimum 60° angle between the lift-

ing lugs and spreader bar/frame.

FIGURE 10 - RECOMMENDED LIFTING WITH

MULTIPLE POINTS

USING FORK LIFT IN SPECIAL

CIRCUMSTANCES

Forklifts should not be used to off-load AHUs except

in special circumstances. If moving an AHU with a

fork lift or similar equipment becomes necessary, make

sure the lifting forks are long enough to reach from the

fork truck to the opposite side and slightly beyond the

AHU. Leave the shipping blocks attached to the bot-

tom of the AHU until it is moved to its final location.

There is no structural support under the equipment ex-

cept what is visible from the perimeter.

SPREADER

BARS

60° MIN

LD13765b

Loading...

Loading...