JOHNSON CONTROLS

98

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

Filter Installation

Installing a 2 in. Pleated Filter

Use the following instructions to install a 2 in. Multi-

Pleat Elite filter into a 16 g galvanized holding frame

with four latches (P/N 026-35788-702), as shown in

Figure 147 on page 95.

1. Install one latch at each corner (4 corners) of the

frame.Thelatchtsintotworowsofthreeknock-

outs. Use the row of knockouts closest to the gas-

ketfornominal1in.ltersorlterswitha13/16

in. single header. Use the second set of knockouts

fornominal2in.lters.

2. Insert the straight end of the latch between the two

knockouts furthest from the corner.

3. Using a moderate amount of pressure, force the

latch over the third knockout. The latch should

now be trapped within the three knockouts, but

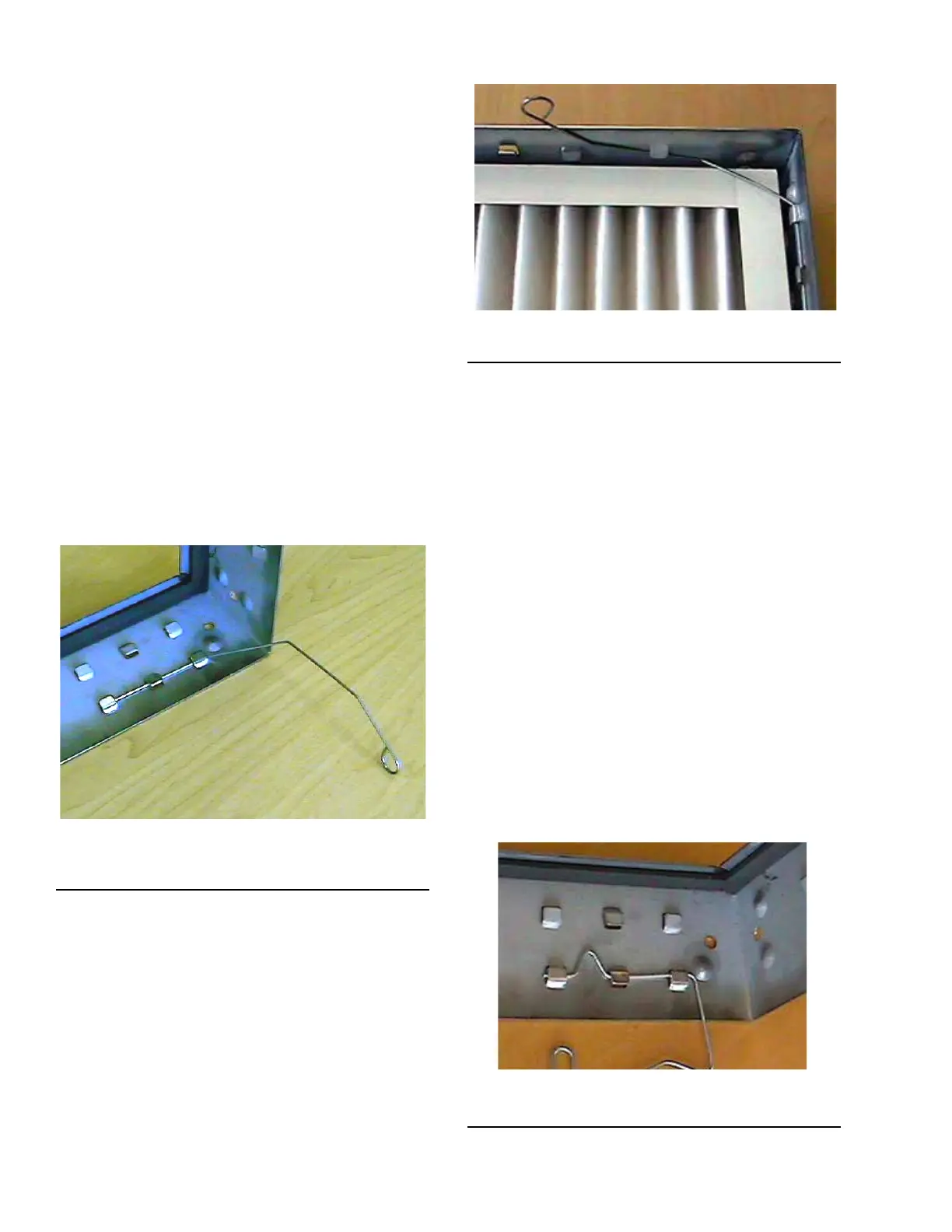

should be able to freely rotate as shown in Figure

148 on page 98.

4. The latch installation should be complete.

FIGURE 148 - CORRECTLY INSTALLED LATCH PIN

(P/N 026-35788-702)

LD10171

5. Install the other three latches into the corners.

6. Rotate all of the latches outward, and insert the

lterintotheframe.

7. Grasp the circular end of the latch, and rotate it

acrossthecornerofthelter.

8. Pushtheendofthelatchtowardsthelteruntilthe

latch catches beneath the knockout on the frame.

9. Repeat the process with the remaining latches.

10. The lter should now be securely installed into

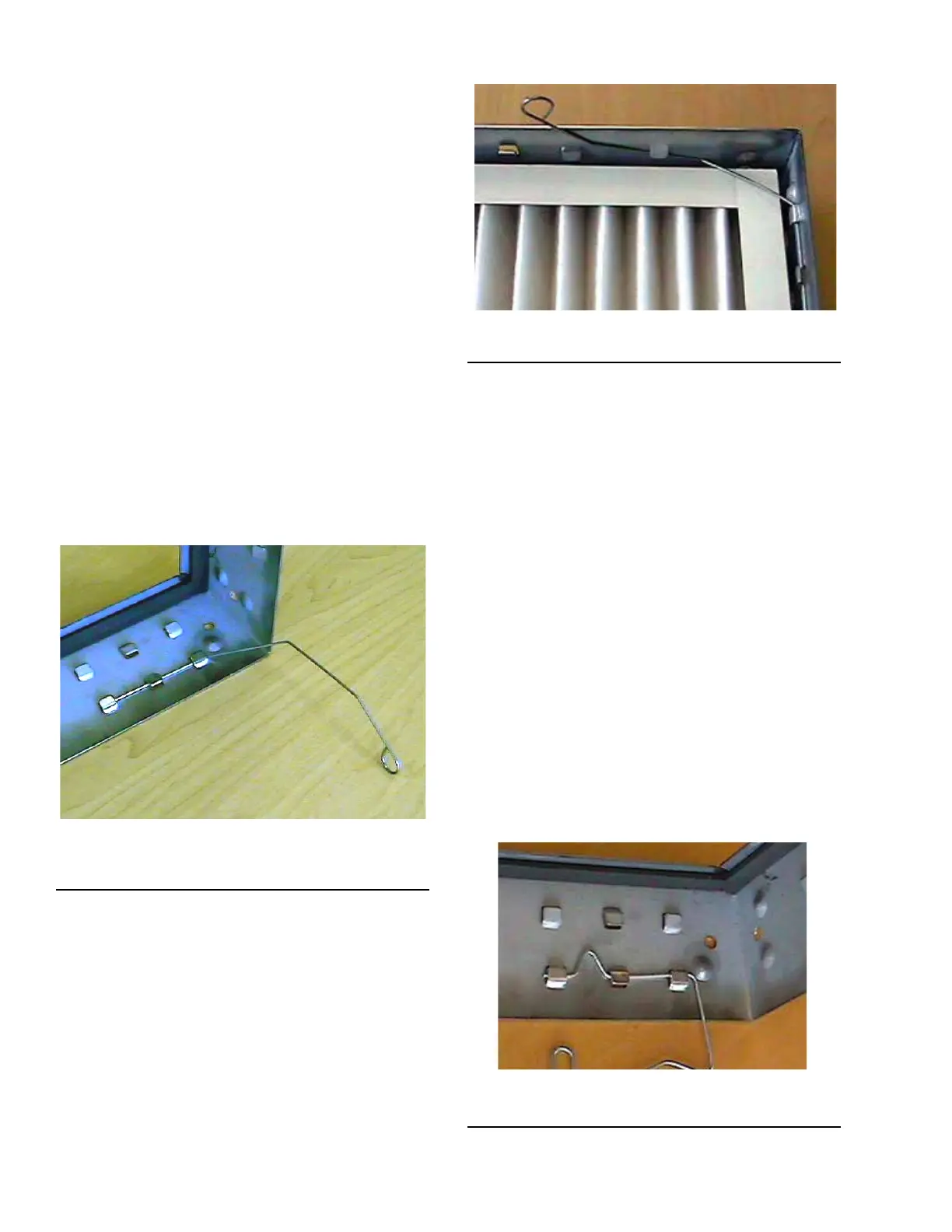

the frame as shown in Figure 149 on page 98.

FIGURE 149 - FULLY INSTALLED FILTER

LD10174

Installing a 4 in. Pleated Filter

Use the following instructions to install a 4 in Micro-

MAX filter into a 16 g galvanized holding frame with

four latches (P/N 026-35778-604), as shown in Figure

147 on page 95.

1. Install one latch at each corner (4 corners) of the

frame.Thelatchtsintotworowsofthreeknock-

outs. Use the row of knockouts closest to the gas-

ketfornominal1in.ltersorlterswitha13/16

in. single header. Use the second set of knockouts

fornominal2in.lters.

1. Insert the straight end of the latch between the two

knockouts furthest from the corner.

2. Using a moderate amount of pressure, force the

latch over the third knockout. The latch should

now be trapped within the three knockouts, but

should be able to freely rotate as shown in Figure

150 on page 98.

3. The latch installation should now be complete.

FIGURE 150 - CORRECTLY INSTALLED LATCH PIN

(P/N 026-35788-604)

LD10177

Loading...

Loading...