76 | 3DGence INDUSTRY F340

In factory each device is subject to the procedure of scanning the table. To provide the optimum print quality it is recommended to

repeat the procedure every several hundred hours of printer operation. It is also recommended to repeat the scanning procedure

in case of encountering problems with print adhesion to the working table or uneven material application by the printer while

printing the rst layers.

The 3DGence INDUSTRY printer is tted with advanced autocalibration algorithm and bed autocompensation. To provide a proper

autocompensation operation it is necessary to perform table scanning. Below we described the principle of operation for the

procedure.

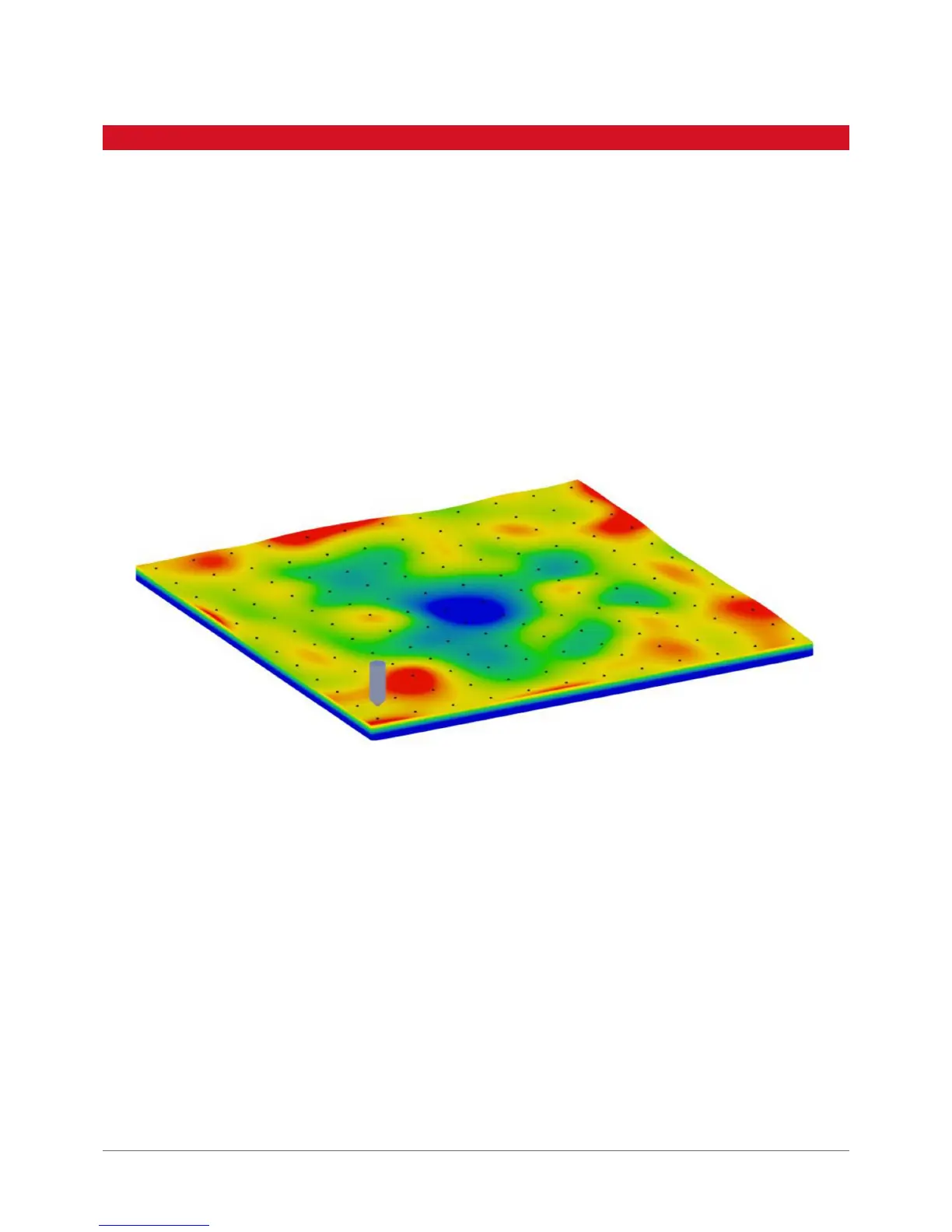

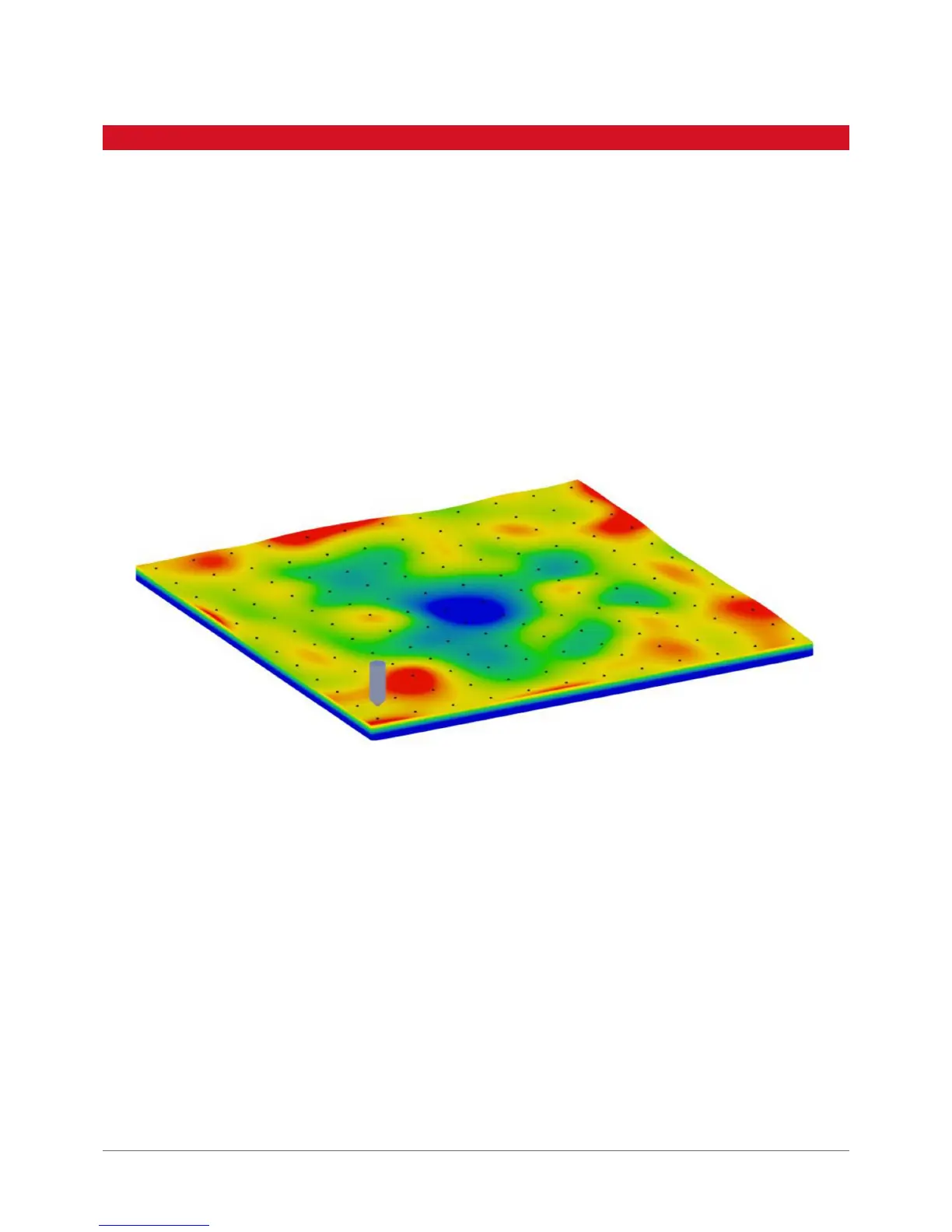

The autocalibration of the bed consists in automatic measurement of the printing bed surface in about 200 points with a pressure

sensor integrated into the printing module. Based on the measurement a virtual table curve map is created that makes up a

base for autocalibration and autocompensation. It is saved in the printer memory and is subject to change only after a complete

working scan is performed (g. 38).

Autocompensation of the bed consists in single-point measurement of the distance to bed and determining a correct distance to

start a job. This process is performed each time before printing. After setting a correct height over a single point, further print will

be performed by taking into account the table curve pattern – thanks to this the distance between the nozzle and the working

table is always the same and controlled in Z axis on a continuous basis.

VII ADDITIONAL INFORMATION

1. AUTOCALIBRATION AND AUTOCOMPENSATION

Fig. 38. Map of the curvature of the table result of autocalibration.

Loading...

Loading...