Refitting the axis 3 gearbox

Use this procedure to refit the axis 3 gearbox.

NoteAction

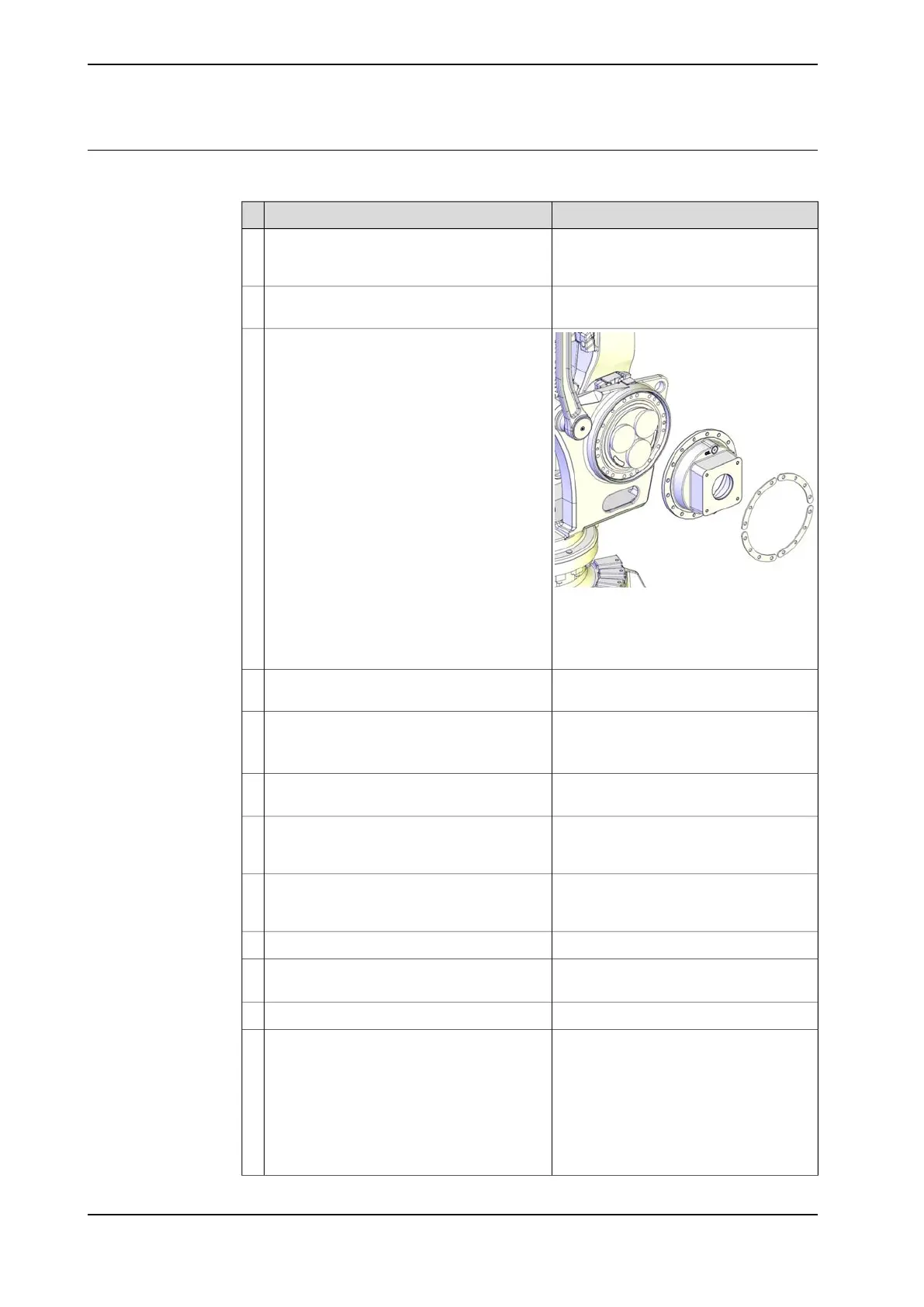

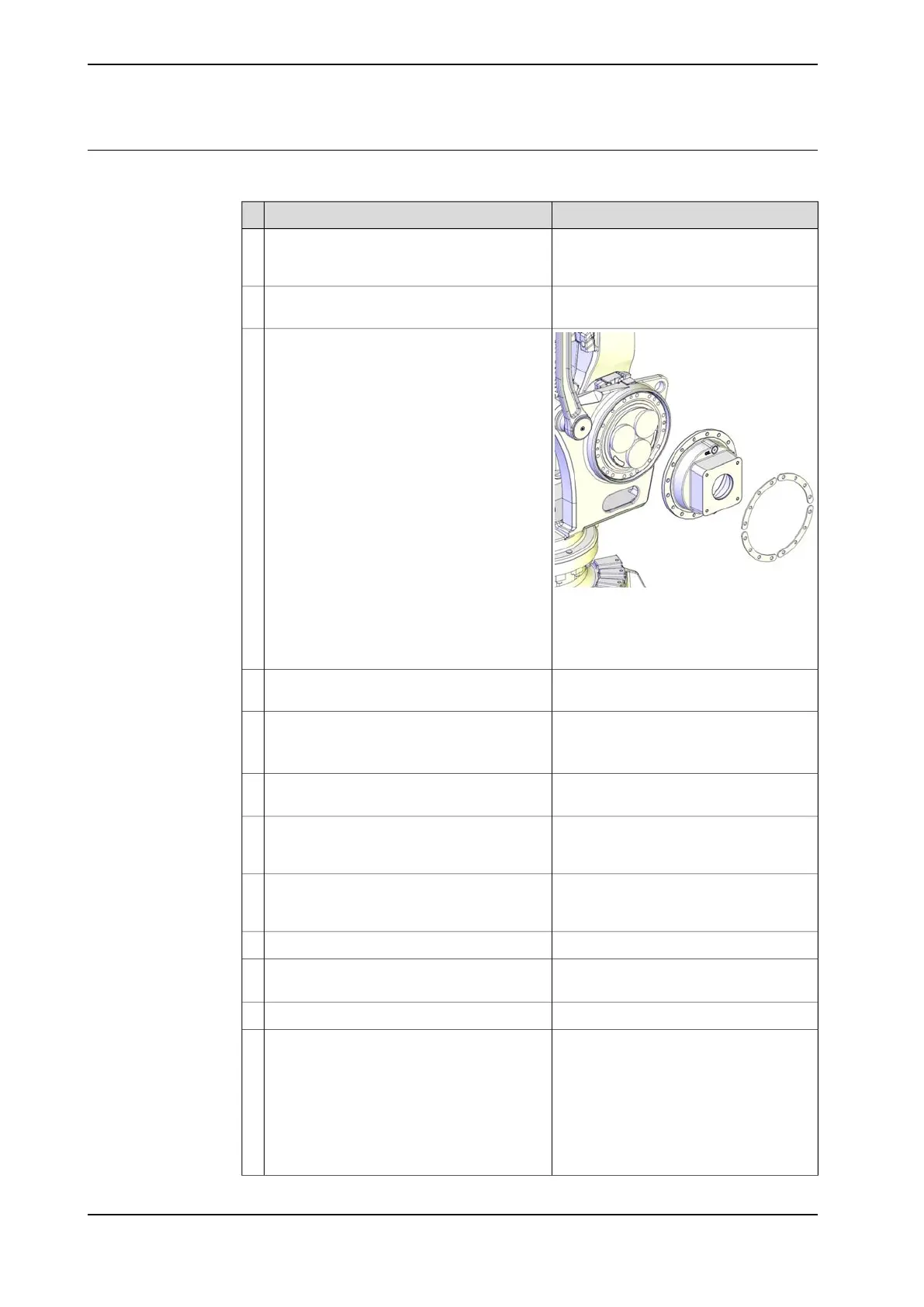

Slide the gearbox carefully on the guide pins

to its mounting position, using an overhead

crane (or similar)..

1

Use a crank to move the gearbox in order to

find the holes for the attachment screws.

2

xx1100000219

Secure the gearbox and the motor flange to

the frame with the attachment screws and

washers.

3

Attachment screws: M12x60 quality 12.9

gleitmo (16 pcs)

Tightening torque: 120 Nm

Remove the guide pins and replace them with

the remaining attachment screws.

4

Attachment screws: M12x40 quality 12.9

gleitmo (21 pcs)

Secure as many attachment screws that is

possible to fit in this position, in the parallel

arm and secure the axis 3 gearbox.

5

Tightening torque: 120 Nm

See Replacing motors, axes 2 and 3 on

page 294.

Refit the axis 3 motor.6

Tightening torque: 120 NmJog axes 2 and 3 to a position where the re-

maining attachment screws can be fitted and

secured.

7

Jog axis 3 (the parallel arm) very carefully to

the position where the parallel rod can be

refitted to the parallel arm.

8

See Replacing parallel rod on page 257.Refit the parallel rod.9

See Performing a leak-down test on

page 140.

Perform a leakdown test.10

Draining, axes 2 and 3 on page 128Refill the gearbox with oil.11

Pendulum Calibration is described in

Operating manual - Calibration Pendulum,

enclosed with the calibration tools.

Recalibrate the robot.12

Axis Calibration is described in Calibrat-

ing with Axis Calibration method on

page 357.

General calibration information is included

in section Calibration on page 347.

Continues on next page

336 Product manual - IRB 460

3HAC039842-001 Revision: P

© Copyright 2012-2018 ABB. All rights reserved.

4 Repair

4.6.3 Replacing the axis 3 gearbox

Continued

Loading...

Loading...