45

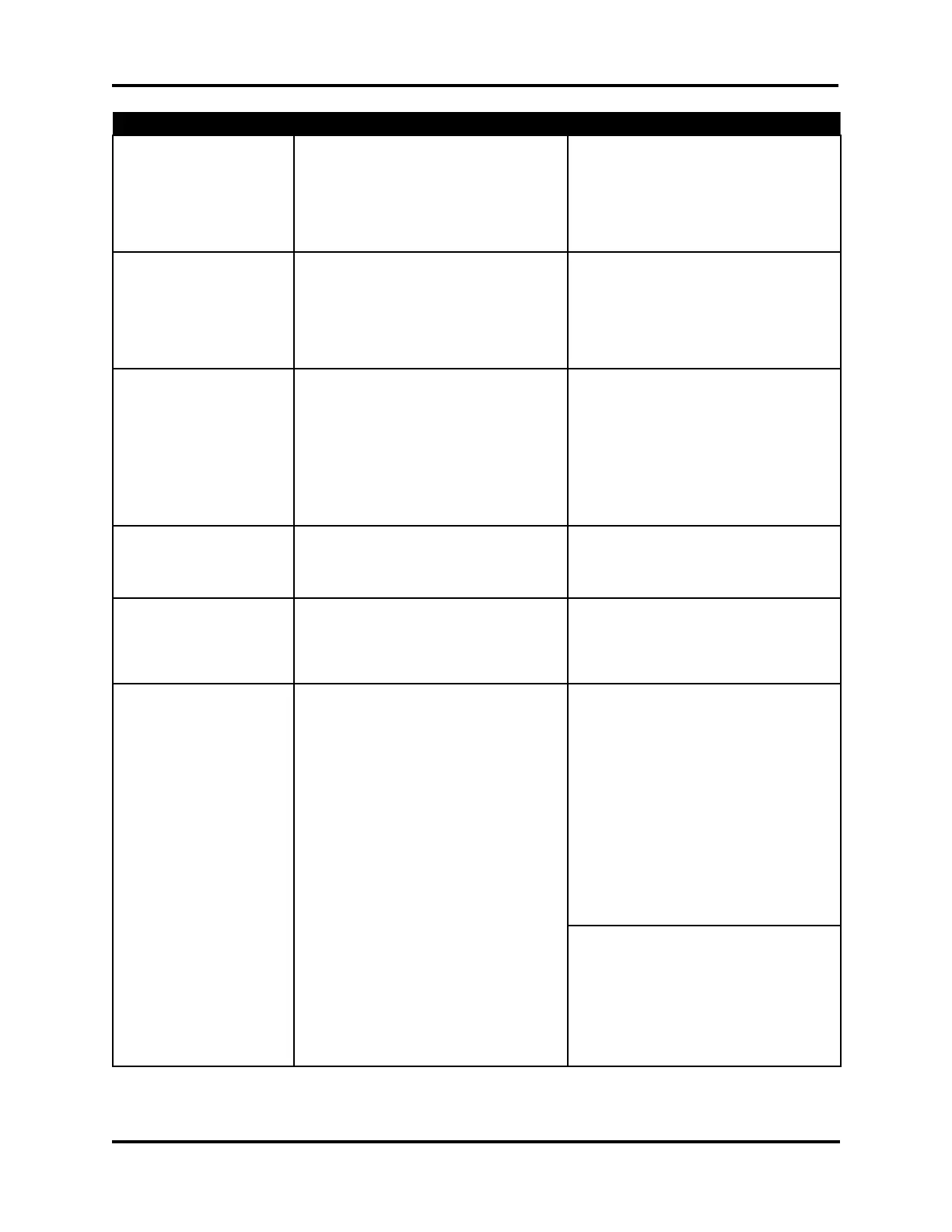

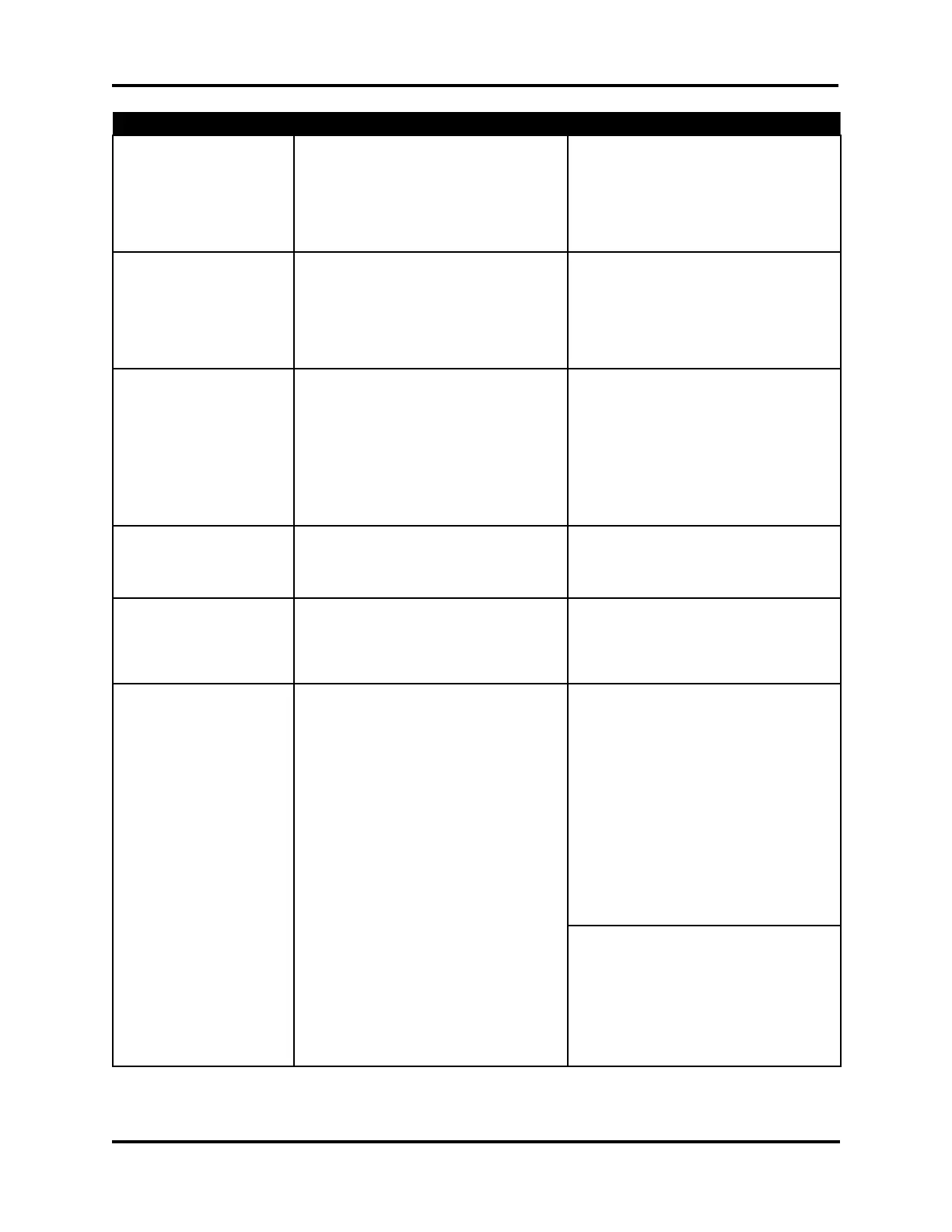

Troubleshooting Table Troubleshooting

Symptom Explanation Suggested Action

24. Keypad keys

unresponsive

Connections to the keypad may have

become disconnected, or the keypad

has failed.

1. Check circuit connections to

the keypad (refer to system

schematic).

2. Replace the keypad.

25. Low Battery The lithium battery contained

inside the NVRAM memory is too

low to maintain stored information,

calibration, and system settings. The

instrument will function normally as

long as the main power remains on.

Contact Advanced Instruments for

Hot-Line Service.

26. Low Fluid Level in

Freezing Chamber

The heat transfer fluid pump may

be malfunctioning, or there may be

a leak or obstruction in the fluid

system.

An insufficient amount of fluid is

being pumped with each head up/

down cycle.

3. Evaluate the functioning of the

heat transfer fluid pump per

the instructions found in the

Maintenance section.

4. If an obstruction is suspected,

refer to Osmometer/Cryoscope

Well Cleaning, located in the

Maintenance section.

27. Memory Allocation

Error

Internal memory management error,

allocated reserved memory conflict.

1. Turn power off, then on.

2. If problem persists, replace the

processor board.

28. “New Software

Version”

EPROM has been changed, or new

software has been downloaded.

1. Check system settings and

proceed.

2. If problem persists, replace

processor board.

29. “No Parameters in

RAM” “Parameter RAM

Failed”

The battery-backed RAM has lost its

data or has been cleared.

The instrument has lost the

calibration, data, and probe bin

numbers from memory.

This may occur during some

software updates.

1. Reset sample and block probe

bin numbers. Recalibrate the

instrument.

2. Reset the stir amplitude.

3. Reset the buzz point (3250 only).

4. Reset plateau mode/range.

5. Reset instrument serial number.

6. Reset any other custom settings

7. If problem persists, replace

processor board.

30. “No Plateau, Repeat

Test ”

The sample did not reach a valid

plateau.

1. Make sure the sample is not too

viscous.

2. Check the sample probe.

3. Make sure there is heat transfer

fluid in the cooling well.

4. Check buzz point setting.

Loading...

Loading...