Chapter 4 Angular Measurements

Angular Position Measurements

4-26 Measurements Reference Guide

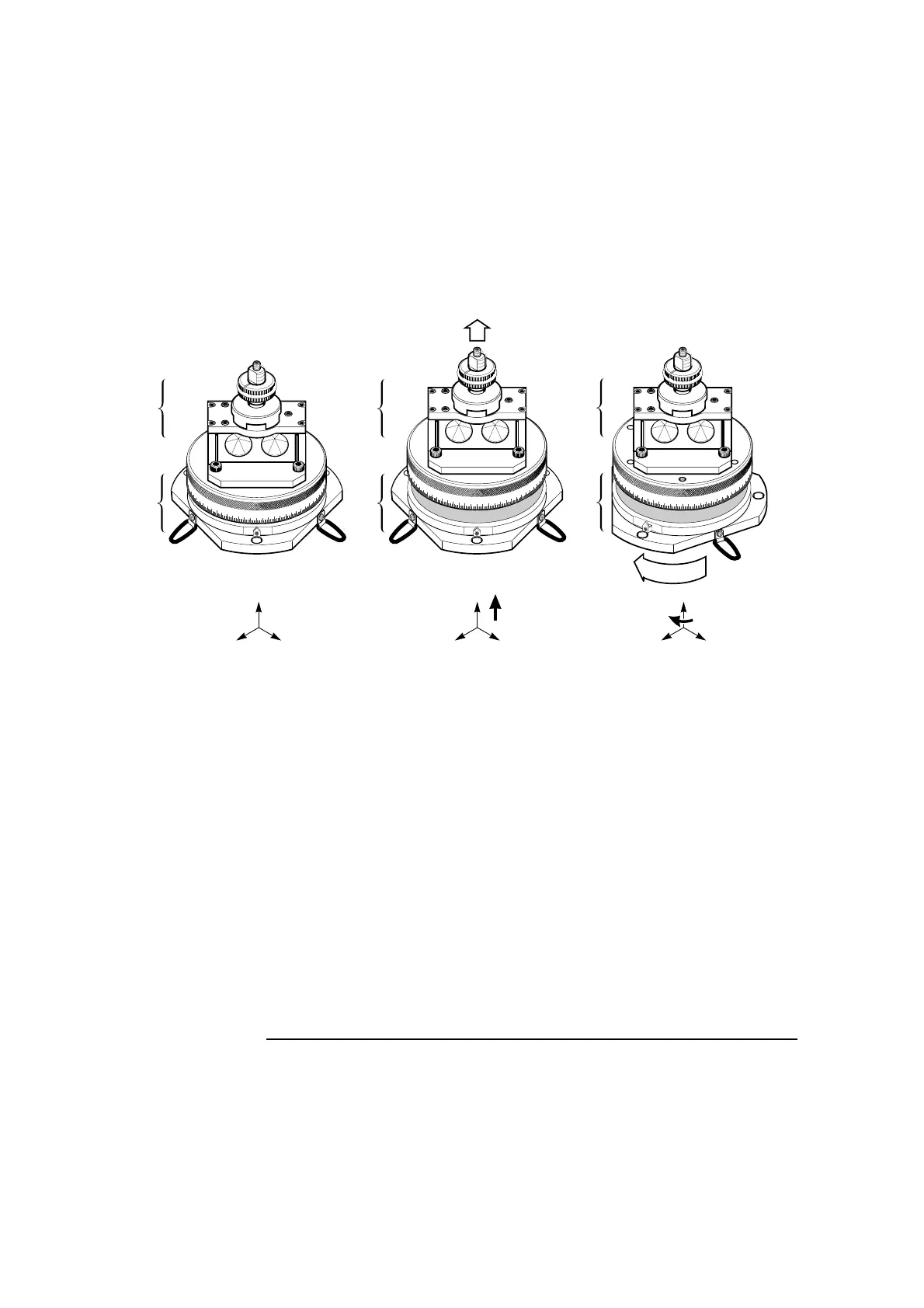

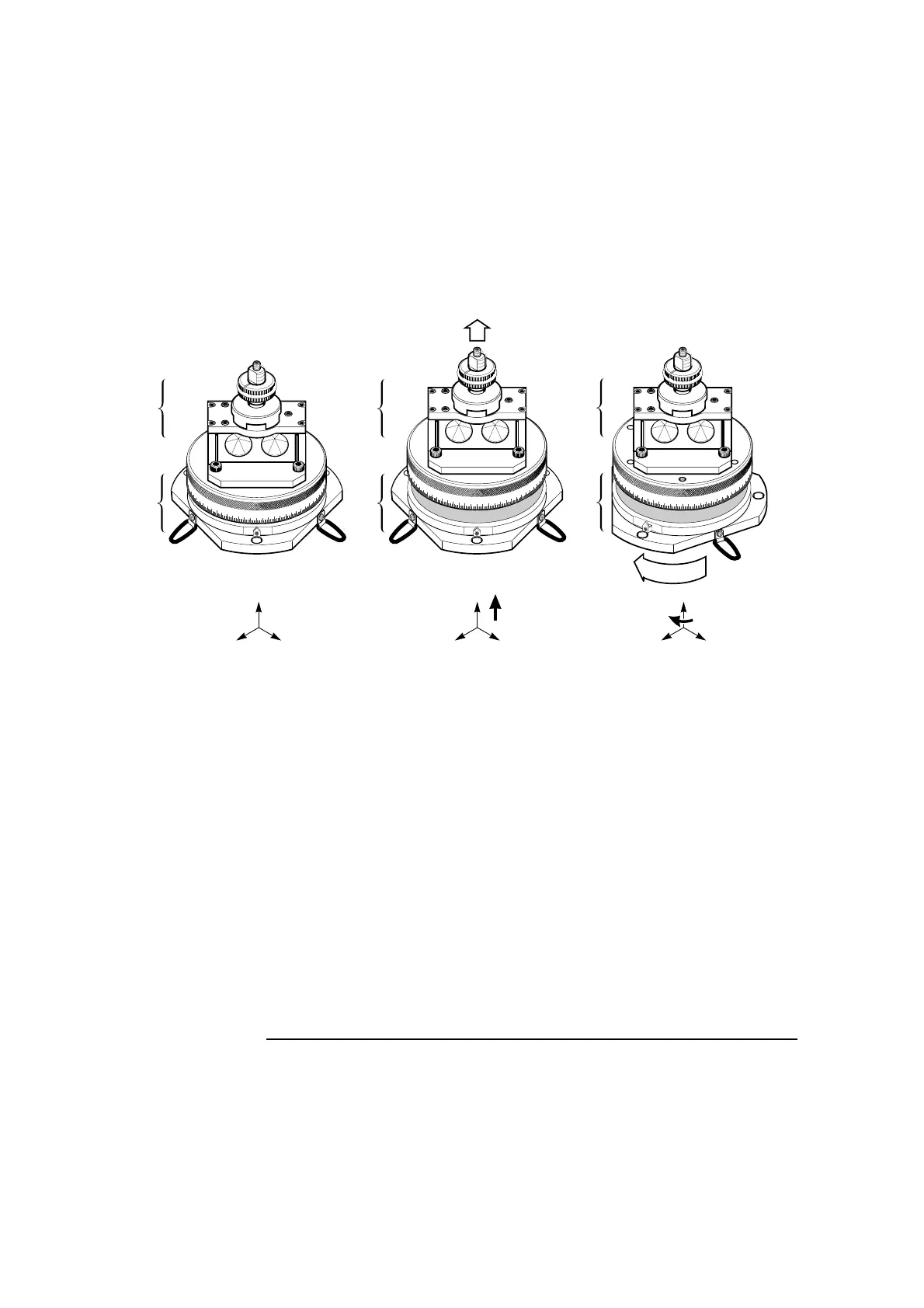

Figure 4-16A. Angular position measurements—principles (Part 1 of 2)

0

10

20

350

30

40

50

60

70

80

90

100

110

340

330

320

0

10

20

350

30

40

50

60

70

80

90

100

110

340

330

320

3

Y

ZX

1

Y

ZX

0

10

20

350

30

40

50

60

70

80

90

100

110

340

330

320

2

Y

ZX

1a

1b

2a

2b

3a

3b

1 Table “neutral” position 2 Table “disengaged” position 3 Table base rotated

1a No force on clutch

For the machine control

program shown in Figure 4-18,

the clutch is depressed 1 mm

from this position. This motion

ensures appropriate

engagement force between the

table’s top and base.

2a Lift top 3 mm to allow base to

rotate. First mm lift returns to

“neutral” position and re-

engages the clutch; remaining

2 mm provides clearance

between table’s top and base,

to allow base to rotate. Set the

machine’s reference point

(relative zero) for this axis after

you have performed this lift.

3a Table top has been disengaged, as

described in 2a.

1b Table top engaged with base 2b Top lifted to allow base to

rotate, as described above.

3b Machine part being calibrated is

rotated, turning the table’s base with it.

Loading...

Loading...