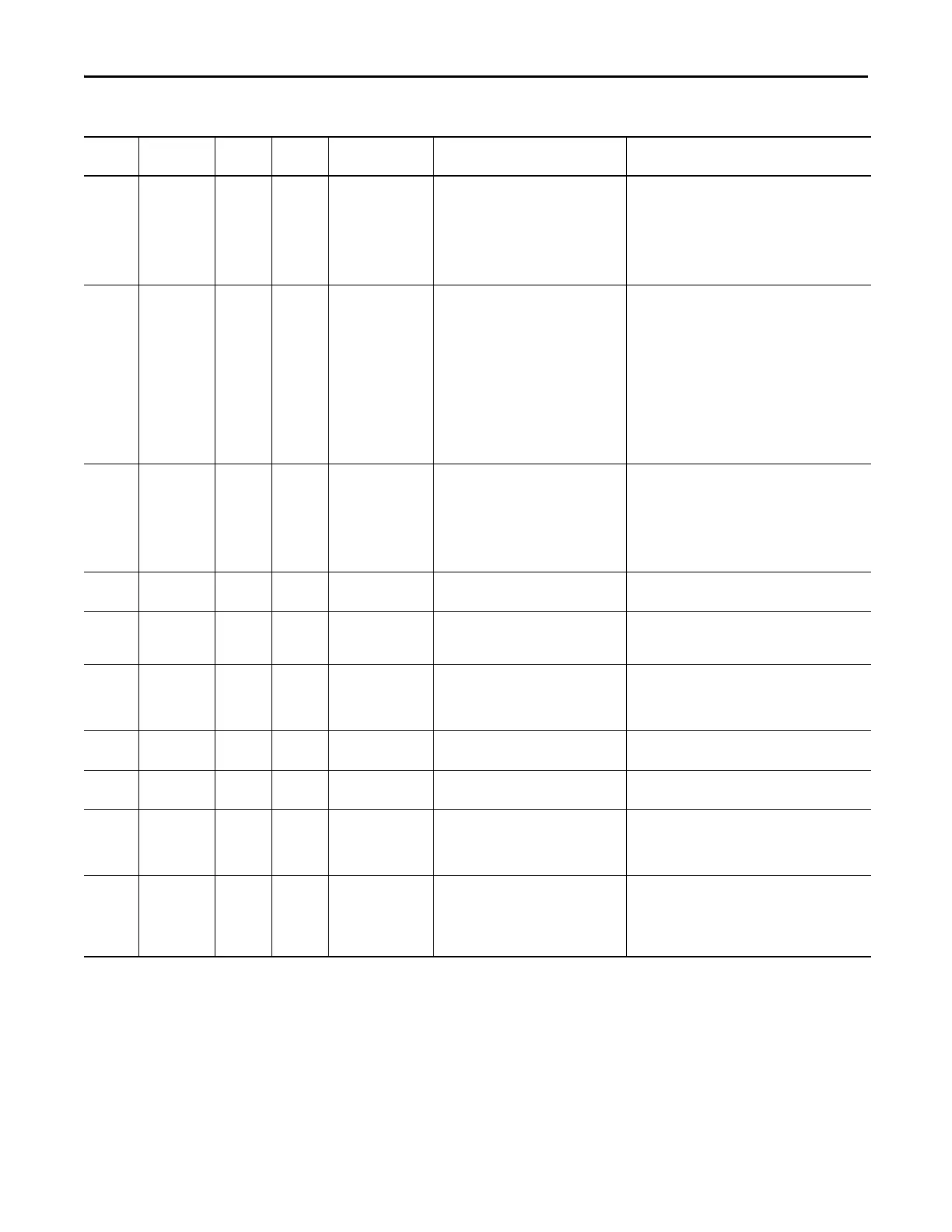

164 Rockwell Automation Publication 290E-UM001B-EN-P - June 2012

Chapter 5 Diagnostics

➊ In the case of a Disconnect open fault, reclosing the disconnect will cause a reset to be issued.

7YesNoOnParameter Sync (PF

4M Codes 48, 71

and 81)

This fault is generated during the

parameter synchronization procedure

between the Control Module and the

internal drive when the syncing process

fails resulting in the drive configuration

not matching the Control Module

configuration.

1. The most common cause of this fault is that the

disconnect has been opened, or that power has

been removed from the drive. To clear the fault,

repower the drive and activate a reset.

2. The drive may have been commanded to default

values. Clear the fault or cycle power to the drive.

8Drive

Controlled

No On DCBusOrDiscnnct ➊

(PF 4M Codes 3, 4

and 5)

This fault is a result of the drive’s Power

Loss (PF 4M Code 3), UnderVoltage (PF 4M

Code 4) and OverVoltage (PF 4M Code 5)

faults. When an Undervoltage occurs

because the Disconnect has been opened,

the condition will be diagnosed as an

“Open Disconnect” trip

1. The most common cause of this fault is that the

disconnect has been opened, or that power has

been removed from the drive. To Clear the fault,

repower the drive and activate a reset.

2. Monitor the incoming line for phase loss or line

imbalance, low voltage or line power interruption.

high line voltage or transient conditions. Bus

OverVoltage can also be caused by motor

regeneration.

3. Extending the [DecelTime1] Parameter 37 or

[DecelTime2] Parameter 70 may also help with this

fault.

9Drive

Controlled

No On Stall Trip

(PF 4M Code 6)

During starting the motor did not reach

running speed within the prescribed

period. This fault occurs when the drive

detects a motor stall condition during

acceleration.

1. Check for source of stall (for example, excessive

load, or mechanical transmission component

failure).

2. Increase [AccelTime1] Parameter 36 or

[AccelTime2] Parameter 69 or reduce load so drive

output current does not exceed the current set by

[CurrentLimit] Parameter 31.

10 Drive

Controlled

No On Over Temperature

(PF 4M Code 8)

This fault occurs when the drive detects a

heat sink over temperature condition.

Check for blocked or dirty heat sink fins. Verify that

ambient temperature has not exceeded 40° C (104° F).

11 No No On Ground Fault

(PF 4M Code 13)

This fault occurs a current path to earth

ground has been detected at one or more

of the drive output terminals.

Check the motor and external wiring to the drive

output terminals for a grounded condition.

12 No No On Restart Retries

(PF 4M Code 33)

Drive unsuccessfully attempted to reset a

fault and resume running for the

programmed number of auto retries.

Correct the cause of the fault and manually clear.

Check [AutoRestartTries] Parameter 84 and

[AutoRestartDelay] Parameter 85 meets application

needs.

13 No No On Drive Hardware Fault Failure has been detected in the drive

power section.

1. Cycle power.

2. Replace unit if failure can not be cleared.

14 No No On Output Short This fault is generated when a hardware

output short circuit condition is detected.

Correct, isolate or remove wiring error prior to

restarting the system.

15 Yes Yes Off User Defined This fault is generated either in response

to the rising edge of user input 0...5,

[Input00Function...Input- 05Function]

Parameter 58...63.

This fault is generated based on user configuration.

This fault may be reset after the condition that caused

it is removed. For example, the Auxiliary Input goes

low or the DeviceLogix logic drives the bit low.

16 No No On Hardware Fault Trip This fault indicates that a serious

hardware problem exists. This fault is

generated when either the PF 4M drive is

not detected or an invalid factory

configuration setting is detected.

Power cycle to correct. If fault persists the ArmorStart

LT requires replacement.

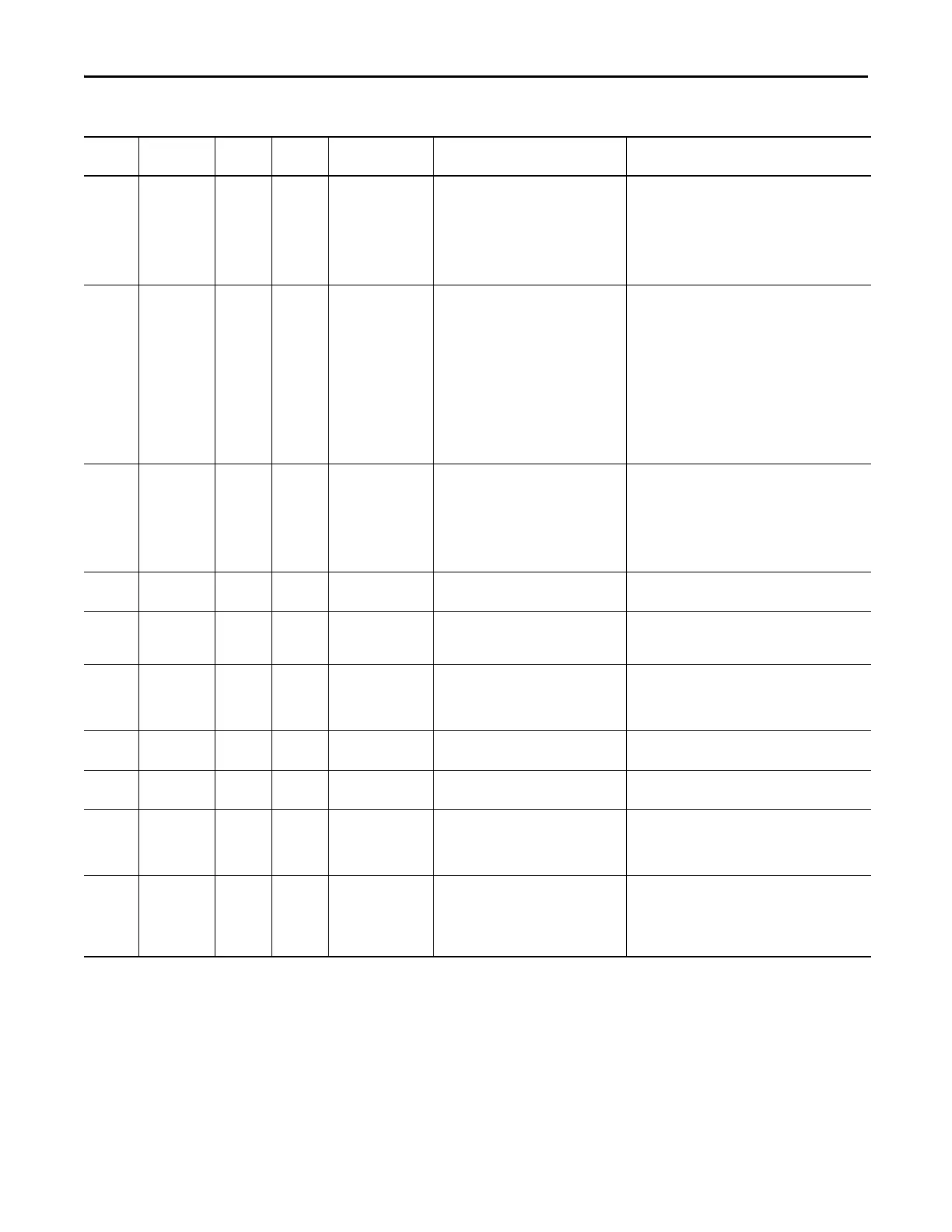

Table 29 - Fault LED Indicator for Bulletin 294E

Blink

Pattern

Auto-Reset

Capable Disable Default

Bulletin 294E

Trip Status Description Action

Loading...

Loading...