Settings

122 KE/KX/KG (RIGID) BAH0089-7 02.2020

8.5.1 Wedge ring roller KW / KWM

1. Uncouple the seed drill.

2. Using the tractor hydraulics, lift the soil

tillage implement just enough for the roller

to clear the ground.

3. Support the soil tillage implement against

unintentional lowering.

4. Loosen the bolt.

5. The distance between the scraper (Fig.

124/1) and the roller tube is 10 mm. Adjust

worn scrapers to the correct dimension or

replace.

6. Rotate the roller to check whether the dis-

tance is maintained at all points.

Fig. 124

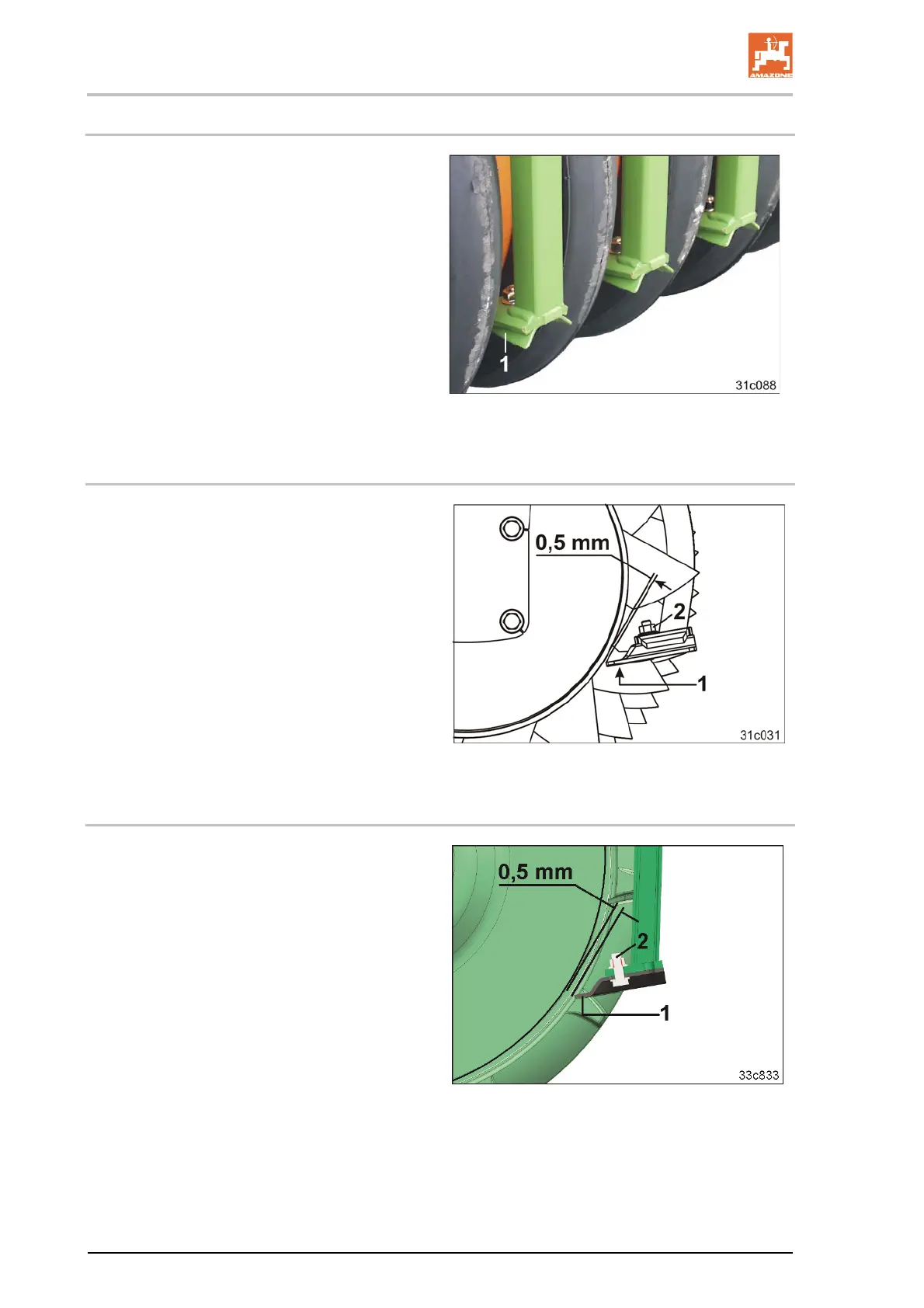

8.5.2 Tooth packer roller PW

1. Uncouple the seed drill.

2. Using the tractor hydraulics, lift the soil

tillage implement just enough for the roller

to clear the ground.

3. Support the soil tillage implement against

unintentional lowering.

4. Unscrew the screw (Fig. 125/2).

5. Screw on the scraper (Fig. 125/1) with a

distance of 0.5 mm to the roller tube.

6. Rotate the roller to check whether the dis-

tance of 0.5 mm is maintained at all points.

Fig. 125

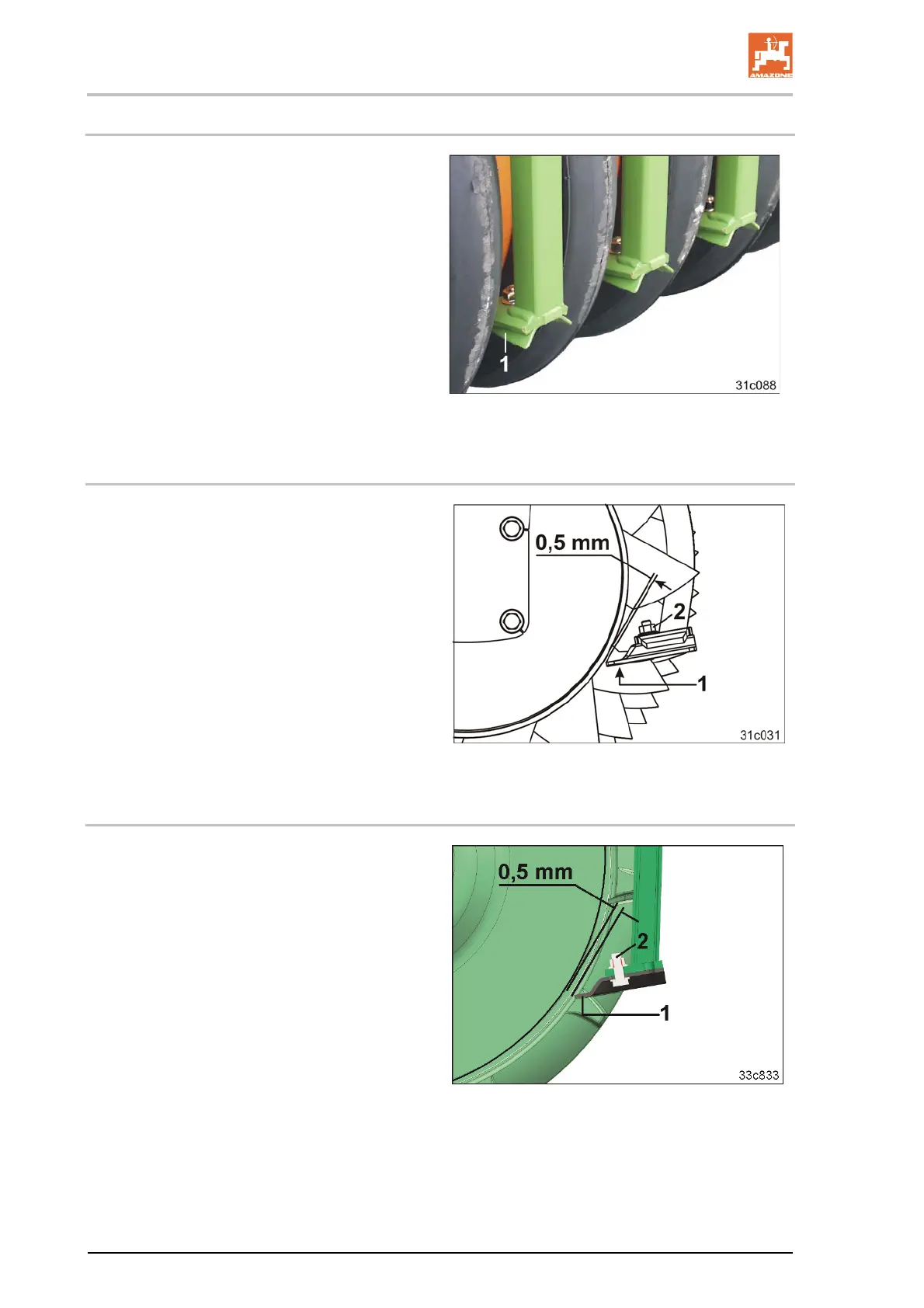

8.5.3 TRW trapeze ring roller

1. Uncouple the seed drill.

2. Using the tractor hydraulics, lift the soil

tillage implement just enough for the roller

to clear the ground.

3. Support the soil tillage implement against

unintentional lowering.

4. Unscrew the screw (Fig. 126/2).

5. Screw on the scraper (Fig. 126/1) with a

distance of 0.5 mm to the roller tube.

6. Rotate the roller to check whether the dis-

tance of 0.5 mm is maintained at all points.

Fig. 126

Loading...

Loading...