24

25

19

D

C

A

C

21

B

19

20

20

8

22

22

23

24

1-64

Released:01/2014

E-mail: service@amfreece.cz; webside: amfreece.com

Phone: +420 582 309 146; Fax: +420 582 360 606

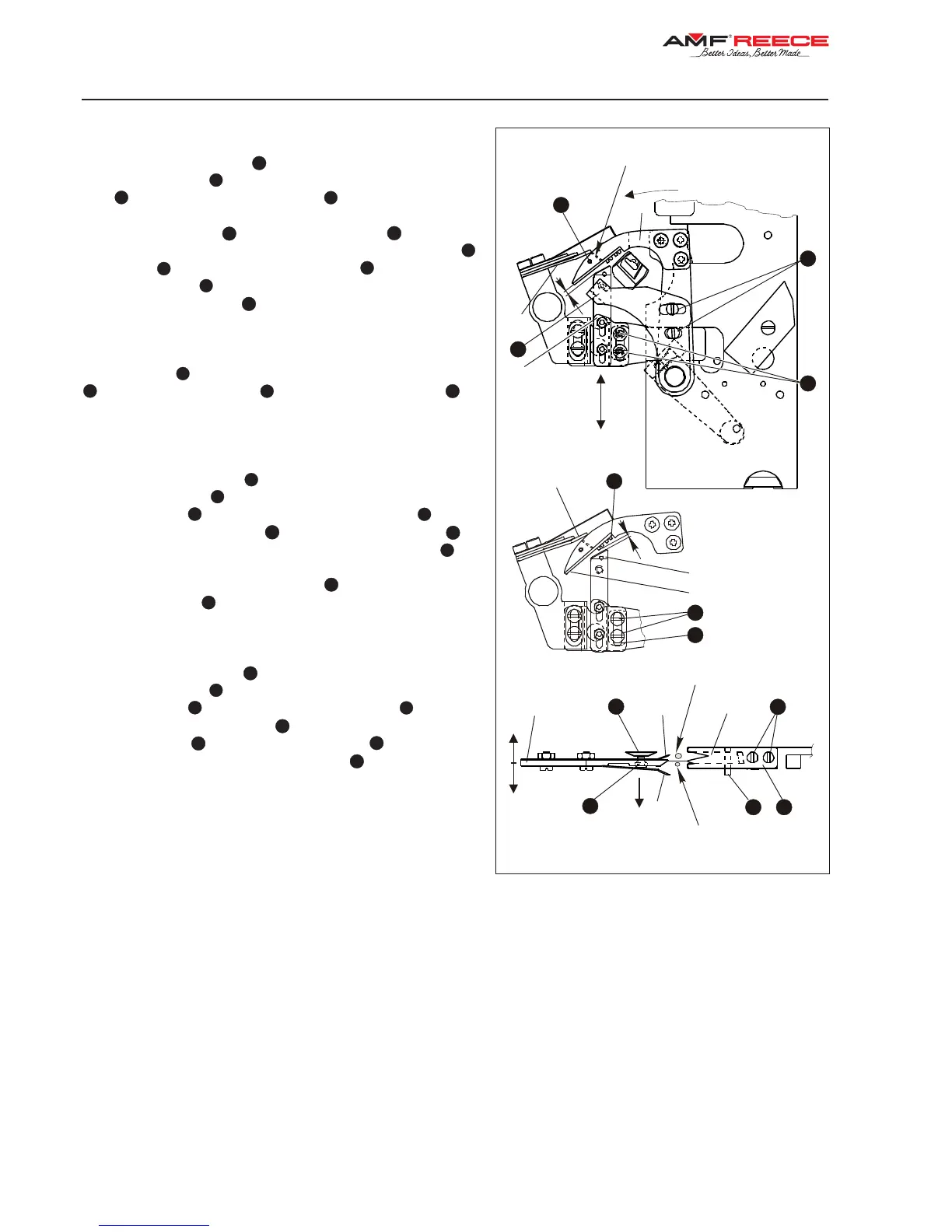

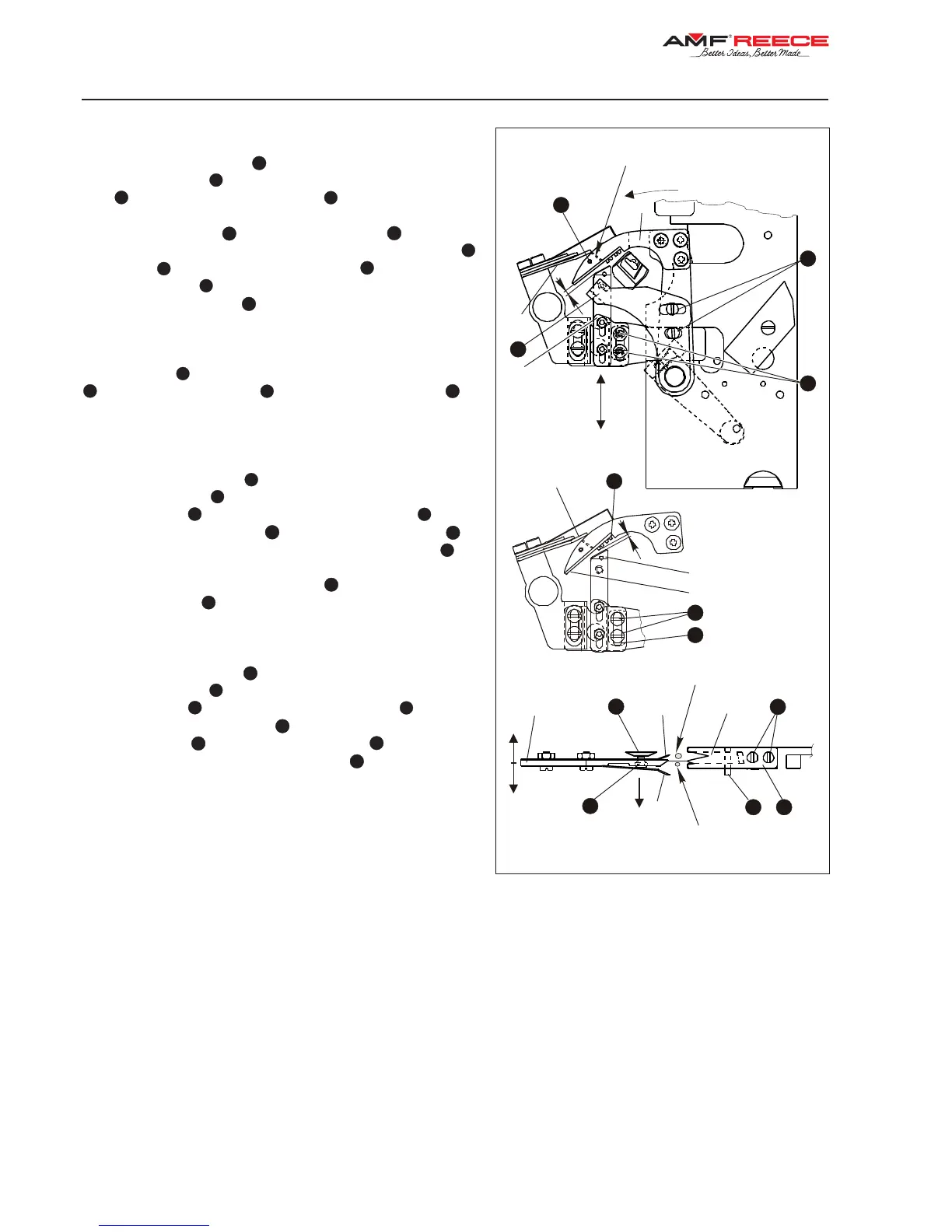

E - STANDARD MACHINE ADJUSTMENT

b) lower thread clamp xing plate adjustment - LTT

b.1. Loosen two screws

in direction Atoalignthexing knife

face

with knife blade section edge

. Then make as small

as possible clearance C (approximately 1mm) between the

thread catching plate

in direction

of arrow B. Check the clearance Dbetweenthexingknife

, whenthe xing knife face

is aligned with

mark on the knife

.

c) lower thread grasping opener - LTT

Turn the knife

in direction Atoalignthexing knife face

is

closed in this position and retains lower thread.

d) looper thread hauling — LTT

d.1. Loosen two screws

in direction of the arrow A to align the

xingknifeface

with the edge of the knife blade

. Align

thelowerthreadxingplate

with thread hauling plate

in

vertical direction - see picture. Then tighten the screws

.

d.3. Sew a sample buttonhole and check if the lower thread

is inserted in the lower thread clamp

and gimp is inserted

in the gimp clamp

.

e) lower thread grasping opener - LTT

e.1. Loosen two screws

in direction of arrow A to align the

xingknifeface

with knife blade section edge

. Turn the

lower thread grasping opener

so that the lower side (slant)

releases the pin

returns to the

closed position. Then tighten the screws

.

Blade section

Gimp

Lower thread

Loading...

Loading...