6 Parameter Settings and Functions

62 © Copyright Reserved Autonics Co., Ltd.

6.3.2.1 Hysteresis Settings

An ON/OFF control feature is used to define the control output ON/OFF points.

ON_Hysteresis sets the output on point and OFF_Offset sets the off point.

Setting hysteresis too low can result in hunting induced by disturbance (noise,

chattering, etc.). To minimize hunting, set ON_Hysteresis and OFF_Offset values

according to the heater or cooler's capacity and thermal characteristics, control

subject and sensor response characteristics, installation conditions, and other

defining factors.

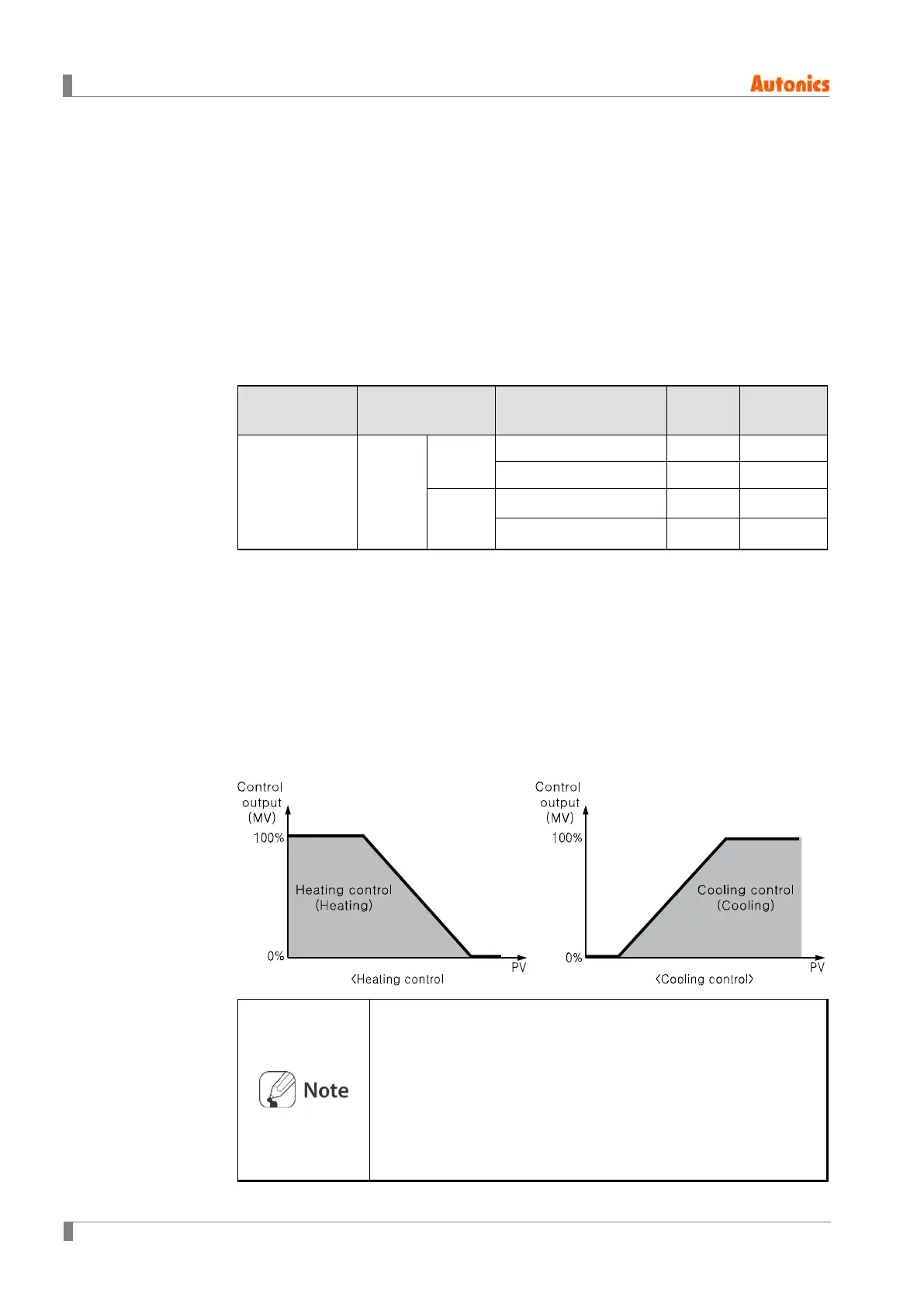

Group

Preceding

Condition

Parameter Range

Factory

Default

Control

Operation

Group

Heating

and

Cooling

Heating

Heating_ON Hysteresis 1~100 2

Heating_OFF Offset 0~100 0

Cooling

Cooling_ON Hysteresis 1~100 2

Cooling_OFF Offset 0~100 0

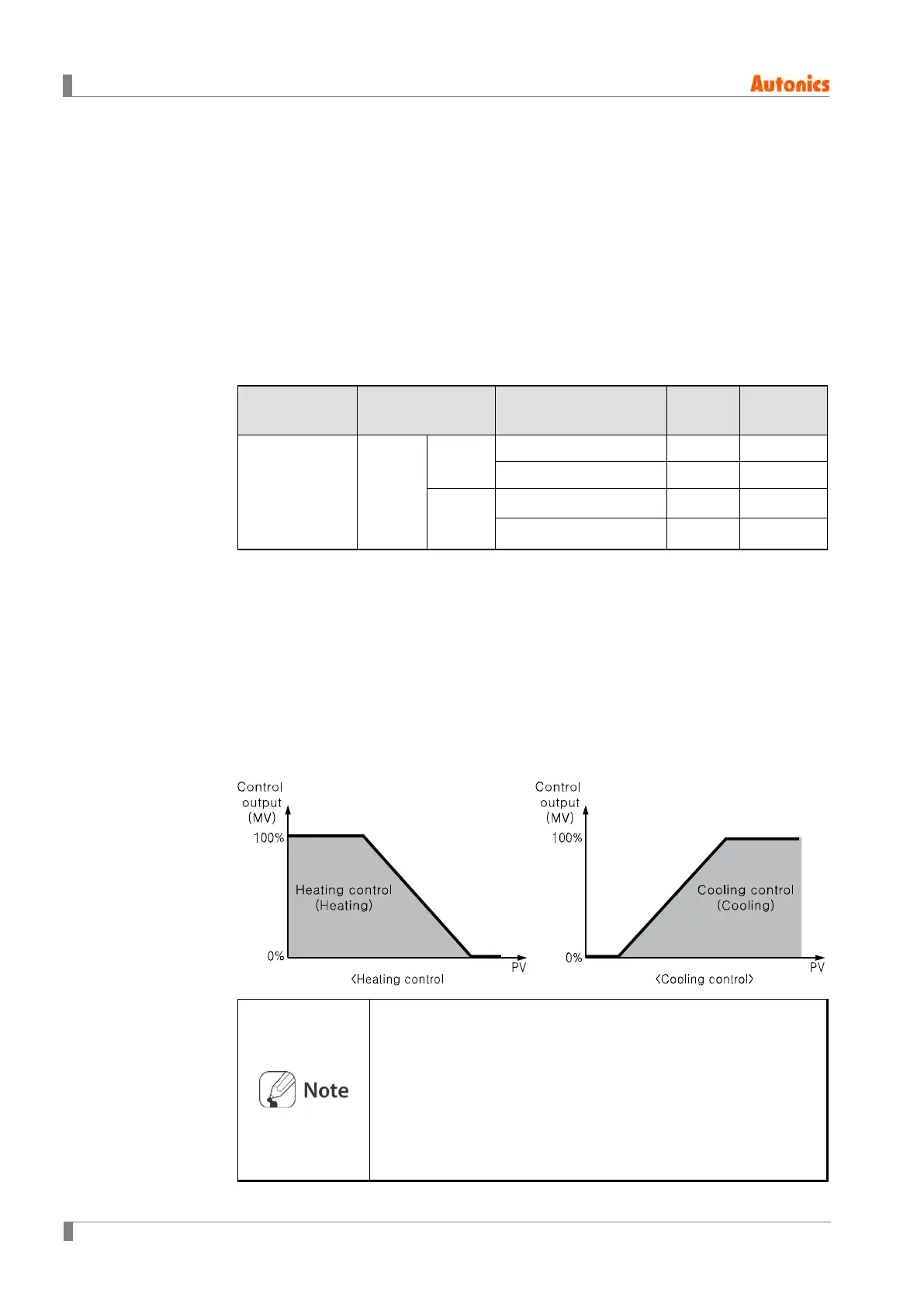

6.3.3 PID Control

PID control is a combination of proportional (P), integral (I), and derivative (D)

controls and offers superb control over control subjects, even with a delay time.

Proportional control (P) implements smooth, hunting-free control; integral control (I)

automatically corrects offsets; and derivative control (D) speeds up the response to

disturbance. Through these actions, PID control realizes ideal temperature control.

How to apply PID control

Proportional (P) control: Set both integral and derivative times to

0 after PID control is selected.

Proportional-Integral (PI) control: Set the derivative time to 0

after PID control is selected.

Proportional-Derivative (PD) control: Set the integral time to 0

after PID control is selected.

When using the multi-SV function, the same PID time constant

will be applied to SV0 to SV3.

Loading...

Loading...