Meter Orientation

Mag meters can operate accurately in any pipeline orientation and can measure volumetric flow in forward and reverse

directions, as long as the pipe is completely full.

OTE: N A "Forward Flow" direction arrow is printed on the detector label.

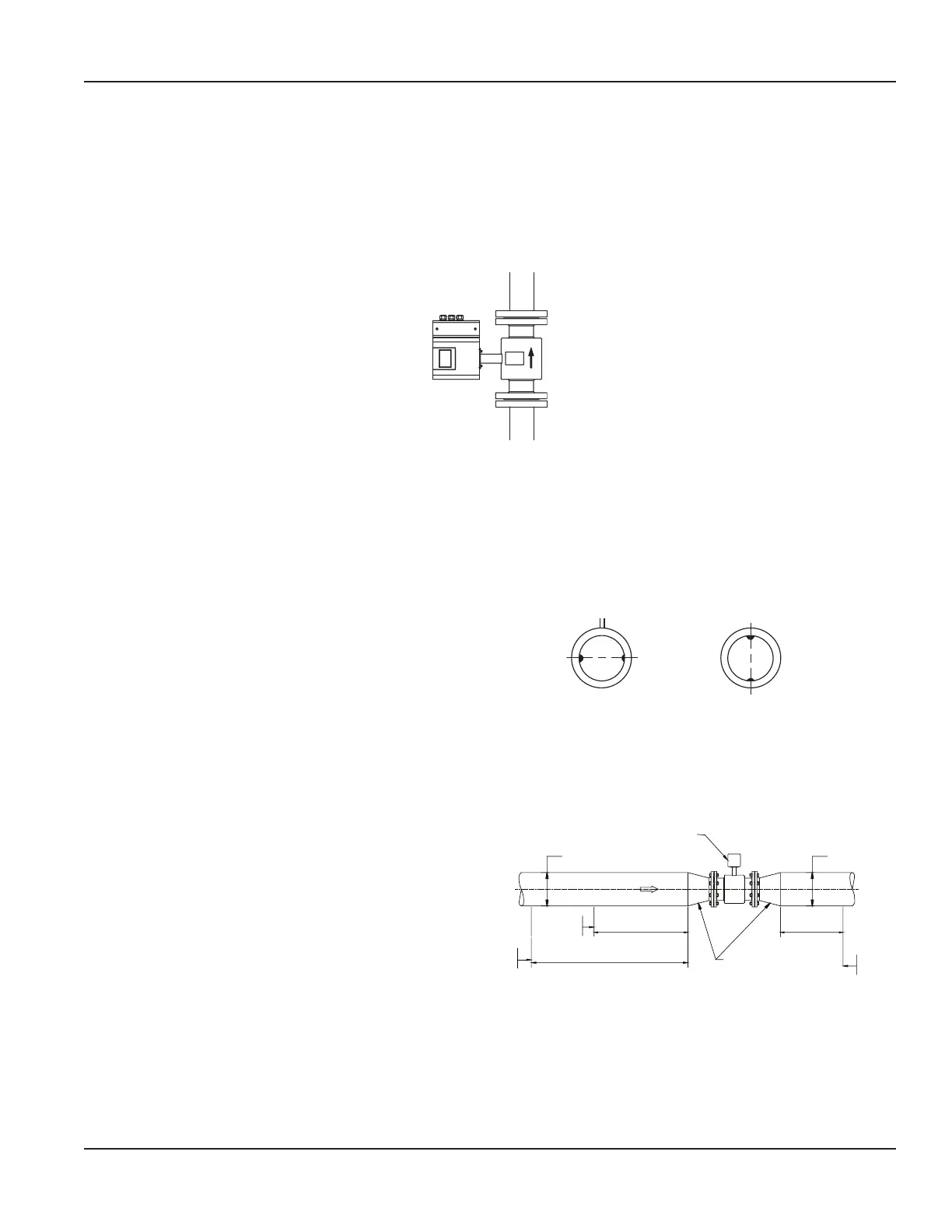

Vertical Placement

Mag meters perform best when placed vertically, with liquid flowing upward and meter electrodes in a closed, full pipe.

Figure 6: Vertical placement

Vertical placement allows the pipe to remain completely full, even in low flow, low pressure applications, and it prevents

solids build-up, sediment deposit and accumulation on the liner and electrodes.

OTE: N Carefully observe the “Forward Flow” label on the meter body and install the meter accordingly. When installed

vertically, rotate amplifier so that cable glands are facing down.

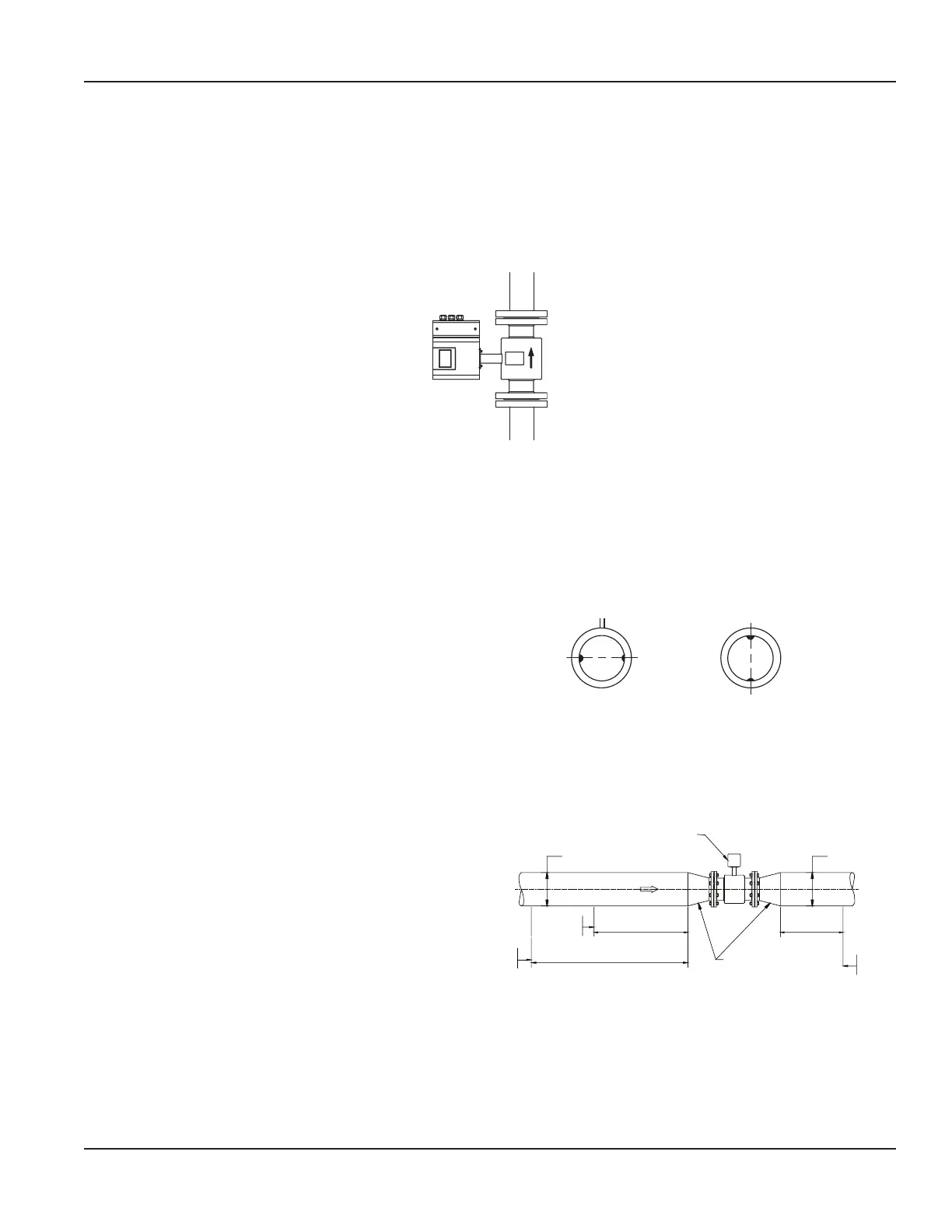

Horizontal Placement

M5000 meters are equipped with an Empty Pipe

Detection feature. If an empty pipe electrode mounted

in the pipe is not covered by fluid for five seconds, the

meter displays an Empty Pipe Detection condition. The

meter sends out an error message and stops measuring

flow. When the electrode is again covered with fluid,

the error message disappears and the meter resumes

measuring.

Electrode

Plane

Plane

Figure 7: Horizontal placement

When installing the meter on a horizontal pipe, mount the detector to the pipe with the flow-measuring electrode axis in a

horizontal plane (three and nine o’clock). This placement helps prevent solids build-up, sediment deposit and accumulation

on the electrodes.

Straight Pipe Requirements

Sufficient straight-pipe runs are required at the

detector inlet and outlet for optimum meter accuracy

and performance. An equivalent of 3…7 diameters of

straight pipe is required on the inlet (upstream) side to

provide a stable flow profile. Two diameters are required

on the outlet (downstream) side.

FORWARD FLOW

MINIMUM STRAIGHT PIPE

MINIMUM STRAIGHT PIPE

ELBOW

TEE

GATE VALVE

(FULLY OPEN)

MINIMUM STRAIGHT PIPE

CHECK VALVE

GLOBE VALVE

Y VALVE

PUMP

ELBOW

TEE

ANY VAL

3 x D

7 x D

2 x D

D (Pipe Size) D (Pipe Size)

MINIMUM PIPING REQUIREMENT

STANDARD CONCENTRIC

REDUCERS

(NO DISTANCE REQUIRED)

Figure 8: Straight pipe requirements

Meter Location, Orientation and Applications

MAG-UM-00219-EN-17 Page 11 June 2021

Loading...

Loading...