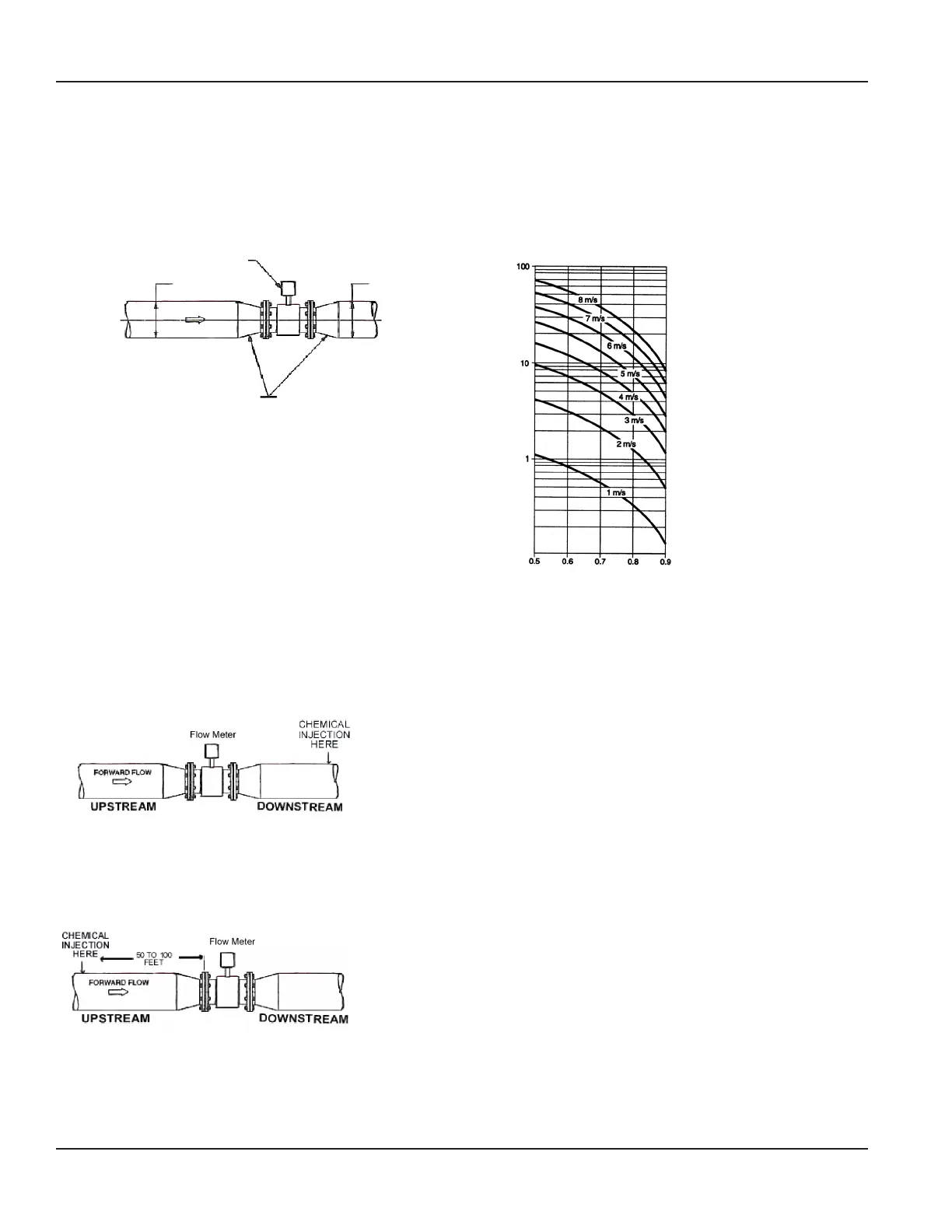

Pipe Reducer Requirements

With pipe reducers, a smaller meter can be mounted in larger pipelines. This arrangement may increase low-flow accuracy.

There are no special requirements for standard, concentric pipe reducers.

Custom fabricated pipe reducers must have a maximum slope angle of 8 degrees to minimize flow disturbances and excessive

loss of head. If this is not possible, install the custom pipe reducers as if they were fittings and install the required amount of

straight pipe.

Forward Flow

Flow Meter

D (Pipe Size)

Standard Concentric

Reducers

(No Distance Required)

Custom Fabricated

Reducers

(8 Degree Slope Angle)

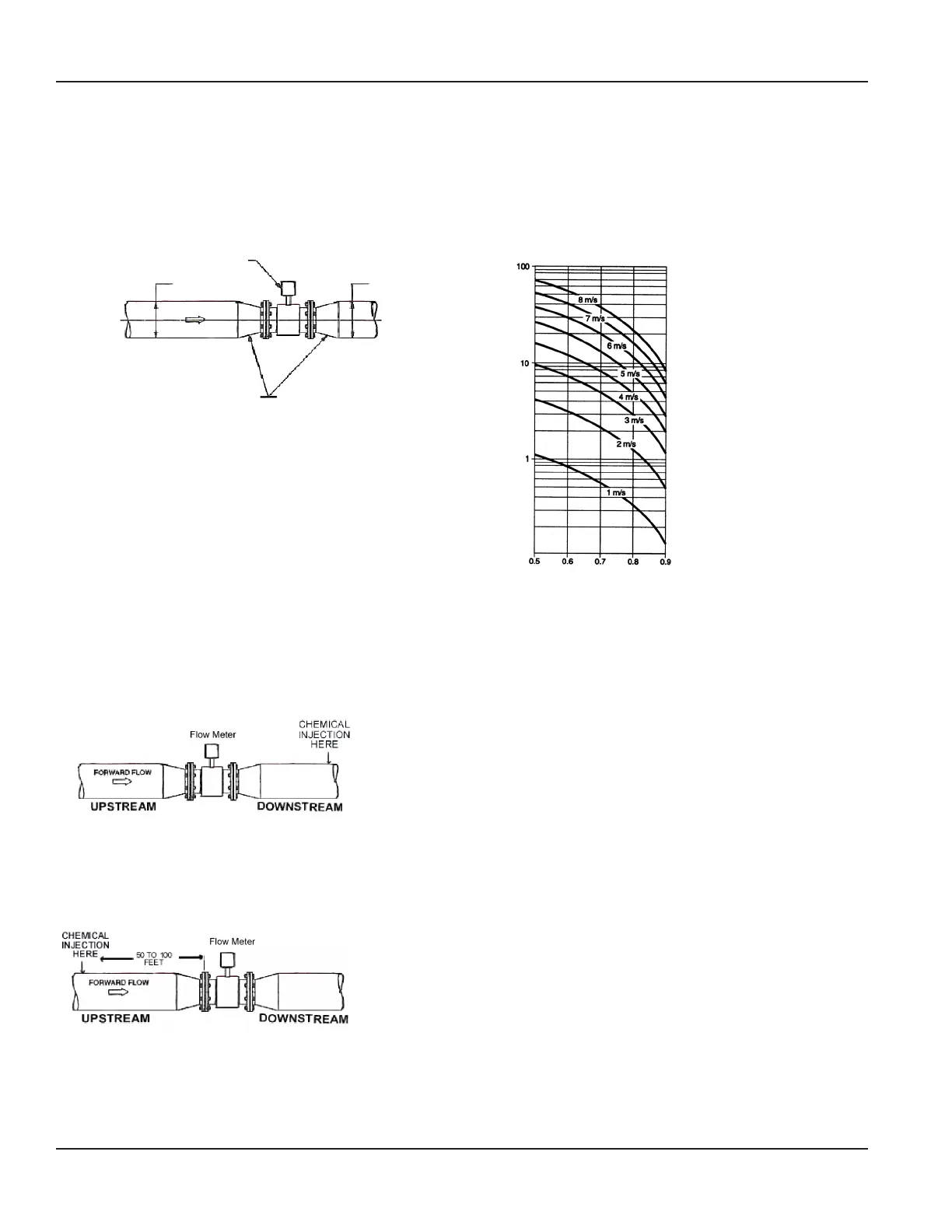

Diameter Ratio d/D

Pressure Drop in mbar

Figure 9: Pipe reducer requirements

Figure 10: Pressure loss chart

Chemical Injection Applications

For water line applications with a chemical injection point, install the meter upstream of the injection point. This eliminates

any meter performance issues.

Figure 11: Chemical injection point downstream of meter

If a meter must be installed downstream of a chemical injection connection, the distance between the flange and the

injection point should be between 50 and 100 feet (15 and 30 meters). The distance must be long enough to allow the water

or chemical solution to reach the meter in a complete, homogeneous mixture.

Figure 12: Chemical injection point upstream of meter

If the injection point is too close, the meter senses the two different conductivities for each liquid. This can cause inaccurate

measurements. The injection method—spaced bursts, continuous stream of drips, liquid or gas—can also affect downstream

readings by the meter.

Meter Location, Orientation and Applications

MAG-UM-00219-EN-17Page 12 June 2021

Loading...

Loading...