Assembly and Operation

A: R82GB0EA.PMD

B: R82DE0EA.PMD

E: 170403 /T. Wenger

G: 020403 / TCS

Section - 5

Page - 3

?

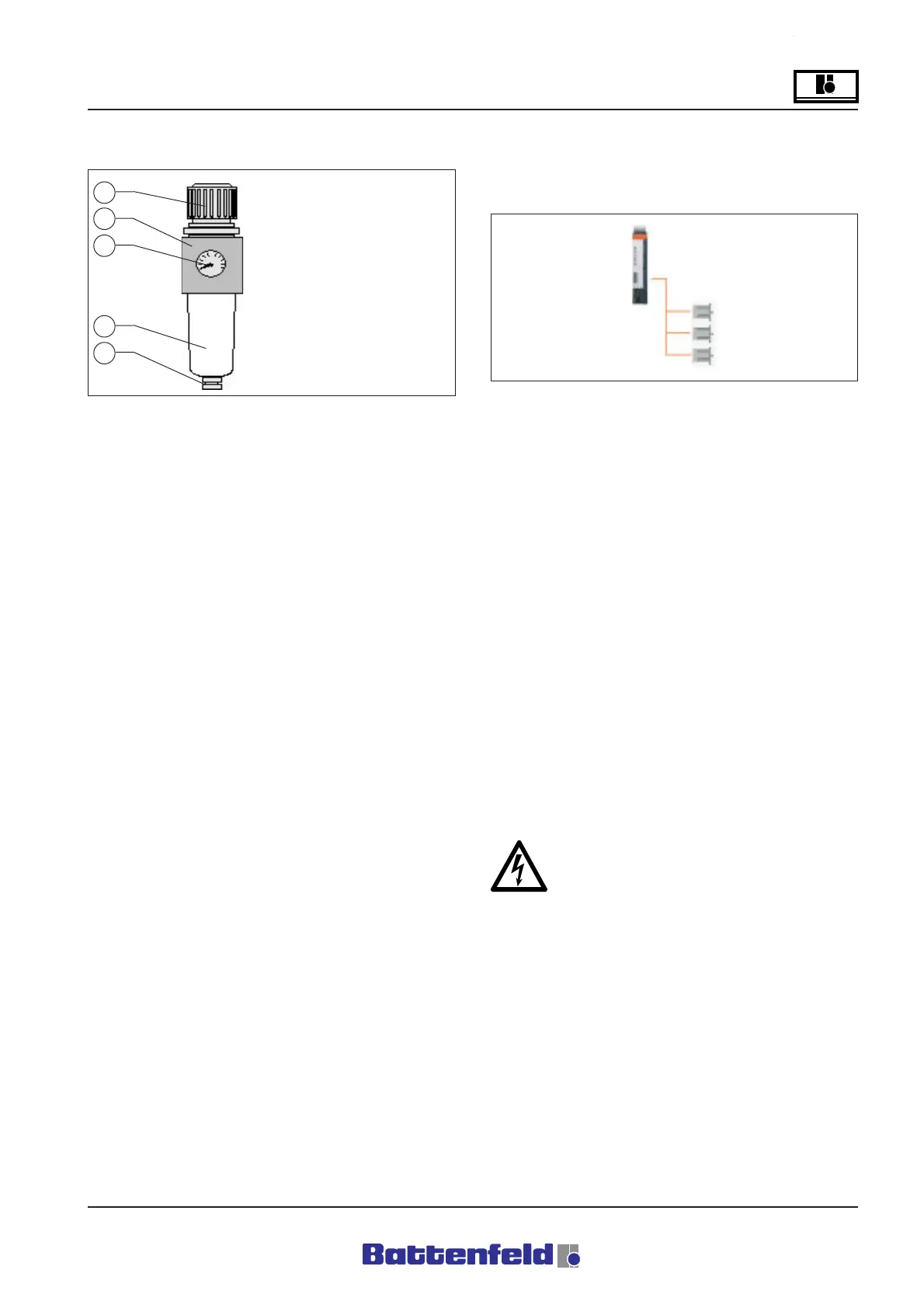

1 - Pressure control valve

adjusting knob

2 - Condensate drain

3 - Pressure gauge

4 - Condensate tank

5 - Drain plug

1

2

3

4

5

R8B2_133.PDF

R8B2_013.PDF

5.2.3 Maintenance unit

The cleaner removes any liquids and solid

materials in the compressed air flow and

regulates the air pressure.

The cleaner may only be used with properly

processed compressed air which does not

contain any aggressive agents.

A filter and a water separator remove any solid

particles and water from the compressed air.

This protects the downstream pneumatic

elements from premature wear.

Attention!

The robot system pneumatics may only be

operated using oil-free air!

5.3. Electrical systems

5.3.1 Electric motors

General:

The three linear axes on the 3-axis handling

device are driven by three motors which are

controlled by a digital servo booster. (B&R/

Type:8V1090.00-2)

Axis change-over:

The motors are activated together with the required

digital inputs/outputs. (e.g. HW limit switch)

The drive is not controlled when it is not moving.

The holding brake keeps the axis in position when

the servo booster is not activated.

The booster communicates with the CP276

controller via CAN. (refer to Section 5.4.2 PCS)

Connections are specified in Section 4.2 Transport

and Installation – Electrical connections.

Electrical components may only be serviced

by qualified electricians!

Loading...

Loading...