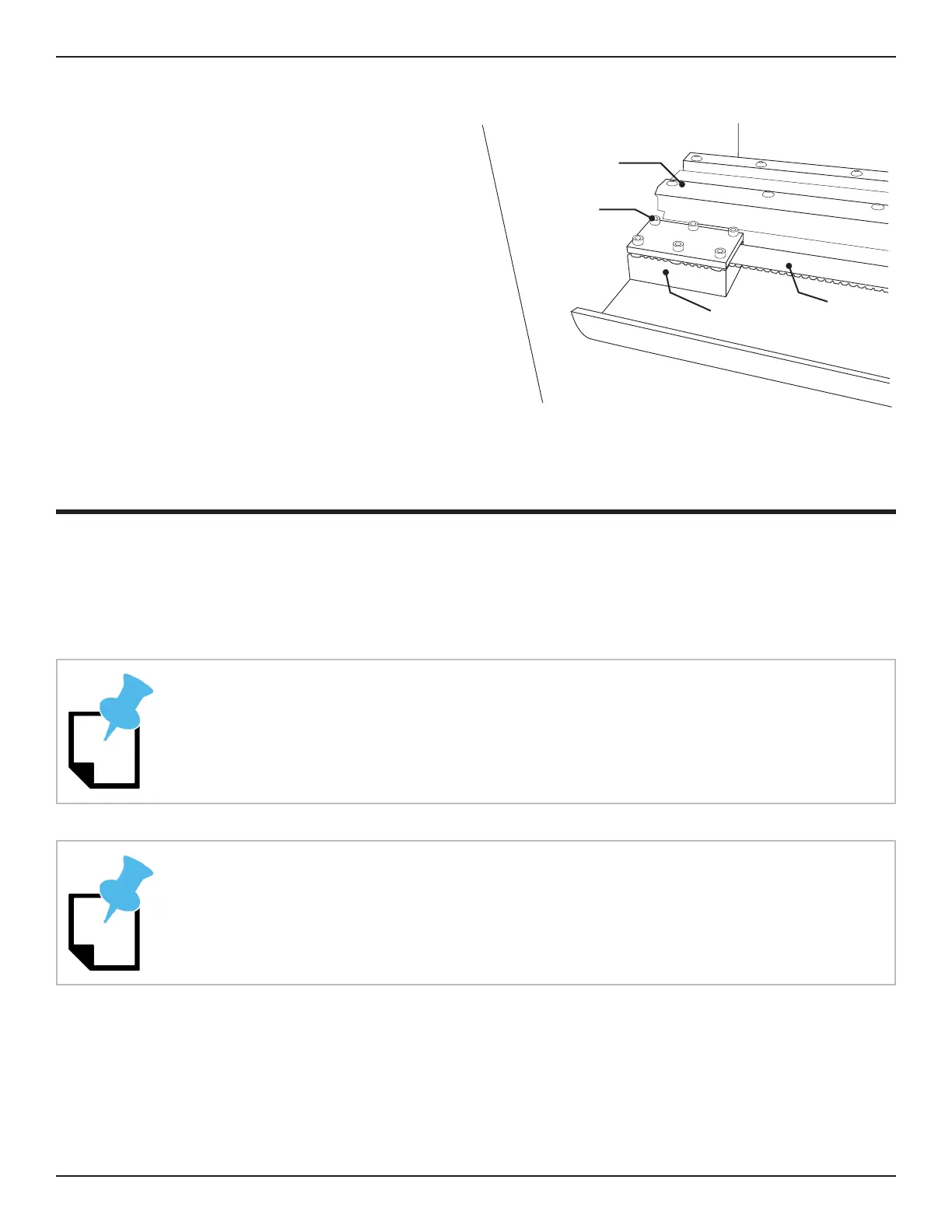

1.4.3 Drive Belt Clamp

Before tensioning the Drive Belt, ensure

it is secured in the rear Clamp Block

properly. The Drive Belt should be straight

within the Drive Belt Clamp. The Drive

Belt should be positioned in the Clamp

Block so it is butting up against the Clamp

Block fasteners, as far away from the Rail

as possible. The Clamp Block should be

securely tightened by hand.

1.5 Drive Belt Tension Procedure

The Operator should ensure the Drive Belt is tensioned properly. If Drive Belt tension is not

set to specication it can result in inconsistent machine operation. It is important to tension the

Drive Belt to ensure consistent operation of the Dragon A400. Before setting Drive Belt tension

ensure all steps in section 1.4 have been performed.

The Drive Belt Tension procedure is also outlined in the Dragon A400 Assembly

Manual, Chapter 4, section 4.3.

When checking or adjusting the Drive Belt ensure the Trolley is positioned at the

mid-way point on the Rail.

Belt Clamp

Belt

Belt Clamp

Bolts

Rail

12 Bend-Tech Dragon A400

Start-Up and Training

Setup Inspection

01

Loading...

Loading...