28 Bend-Tech Dragon A400

Assembly Manual

Drive Belt Installation

04

The Installer should remove the shrink wrap and unroll the Drive Belt while slowly walking

toward the Tail of the machine. Avoid twisting the Drive Belt as it is unrolled. Once the Drive

Belt is fully unrolled, ensure it is not twisted and that the Drive Belt is in proper position along

the entire length of the machine.

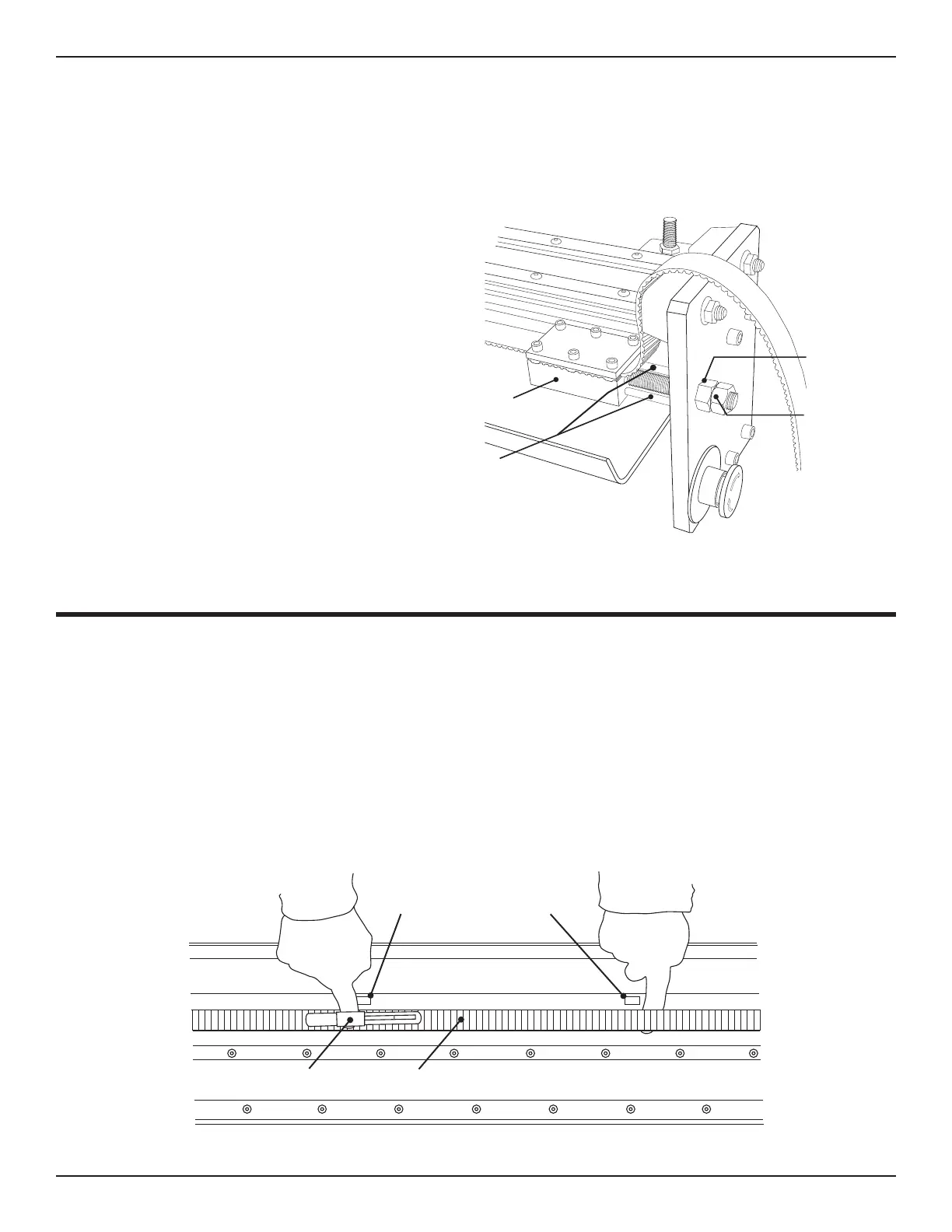

Insert the Drive Belt Clamp Block

into the mounting pins at the Tail of

the machine, feeding the Drive Belt

adjustment threaded stud through

the hole. Thread one of the nuts

onto the adjustment stud and snug

4.3 Tensioning the Drive Belt

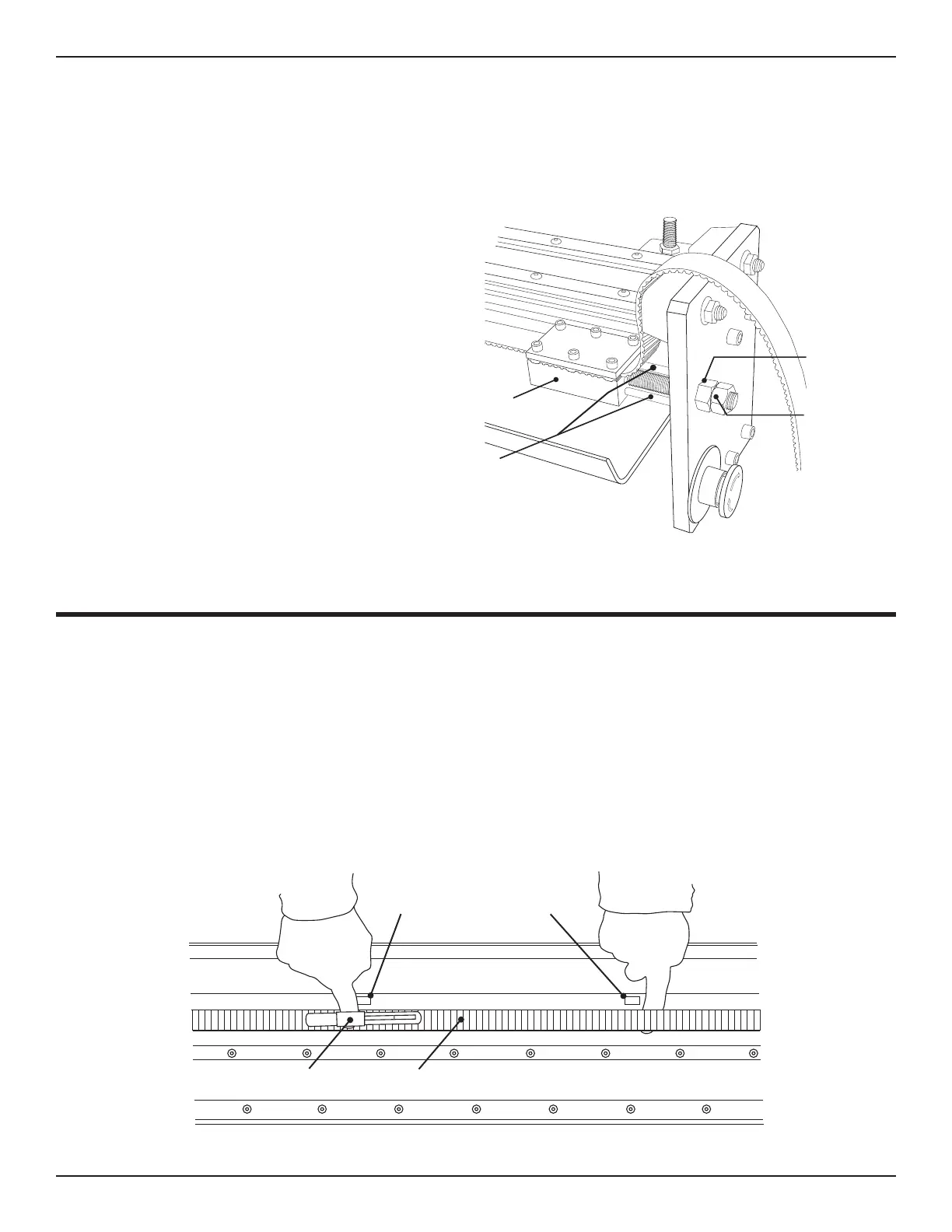

When checking the Drive Belt tension ensure the Trolley is positioned at the mid-way point on

the Rail. Lay a tape measure on the cable track with 0 on the tape positioned where the Drive

Belt enters the Drive Belt Clamp Block. Using the Belt Tension Tool from the Miscellaneous

box, position the tool one foot from the Drive Belt Clamp Block.

with the left hand.

Mounting Pins

Rear Belt Clamp

Tension Nut

Locking Nut

1 ft. 2 ft.

Belt Tension Tool Belt

1 ft. 2 ft.

Loading...

Loading...