24 ATICS-2-ISO_D00046_04_M_XXEN / 03.2021

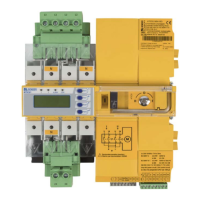

System description

3.5.2 IT system monitoring

Insulation monitoring

The integrated insulation monitoring device measures the insulation resistance on AC IT systems, which

may also contain DC voltage components. Adaptation to the system leakage capacitances occurs auto-

matically. The measuring time increases as the system leakage capacitances increase.

Load current measurement

The load current on the IT system is measured using an STW2 measuring current transformer.

Temperature monitoring

The temperature in the transformer winding is measured via PTC thermistors.

Evaluation

If any of the measured values does not fall within the limits, an alarm is triggered. A message appears

on the LCD, the "ALARM" LED lights up, the alarm relay trips (if set) and this alarm is forwarded to other

Bender devices (such as an alarm indicator and test combination) via the BMS bus.

Locating current injector

When an insulation fault is detected in an IT system, the integrated locating current injector generates

a defined locating current signal to locate the insulation fault. The locating current is limited to max.

1 mA. This function can be enabled or disabled (see chapter „Settings menu 4: IT system“ on p. 71).

I

Caution! The locating current flowing between the IT system and earth can cause controller

faults in sensitive parts of the system, such as PLC or relay. It must therefore be ensured that the

locating current is compatible with the monitoring system.

3.5.3 Monitoring the device functions

The control circuits are designed in such a way that, even though it is almost certain that a particular

fault will occur, it cannot cause the power supply at the output of the automatic transfer switching de-

vice to fail.

ATICS® tests the position of the switch as well as coils 1 and 2 of the switch once a day at around

12:00 pm.

Loading...

Loading...