63 MT55 Operation & Maintenance Manual

LIFT ARM BY-PASS CONTROL

Inspection

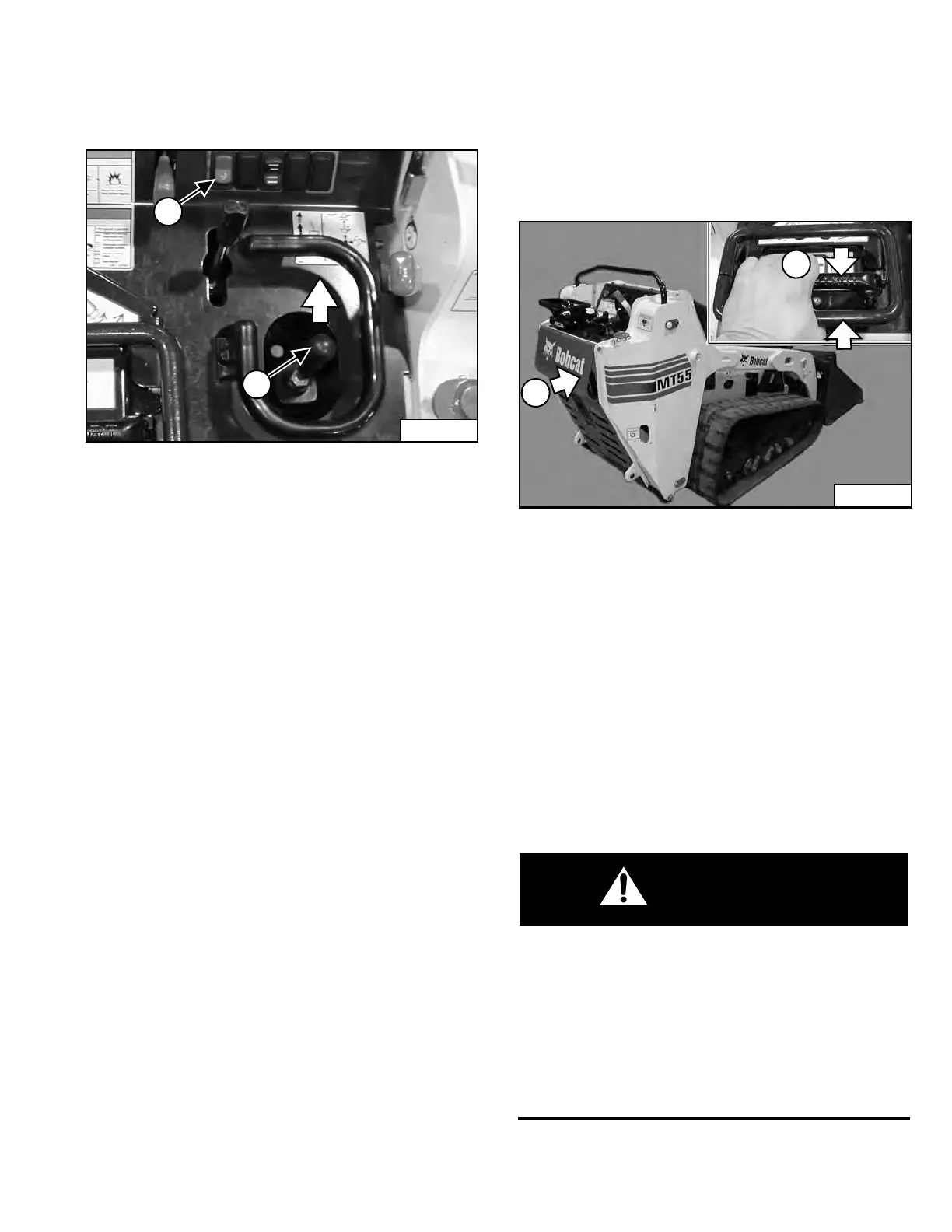

Figure 69

1. Stand in the operator's position, start the engine and

raise the lift arms about 914, mm (3 ft) off the ground.

Stop the engine. Engage the parking brake.

2. Make sure the area around the machine is clear of

bystanders.

3. Press and hold the switch for the lift arm by-pass

(Item 1) [Figure 69].

4. Move the lift arm control lever forward slightly (Item 2)

[Figure 69]. The lift arms should slowly lower. See

your Bobcat dealer for repair if by-pass does not

function correctly.

REVERSE STOP PANEL

Inspection

The Reverse Stop Panel will stop the mini track loader

from moving backward when the panel is pushed

forward.

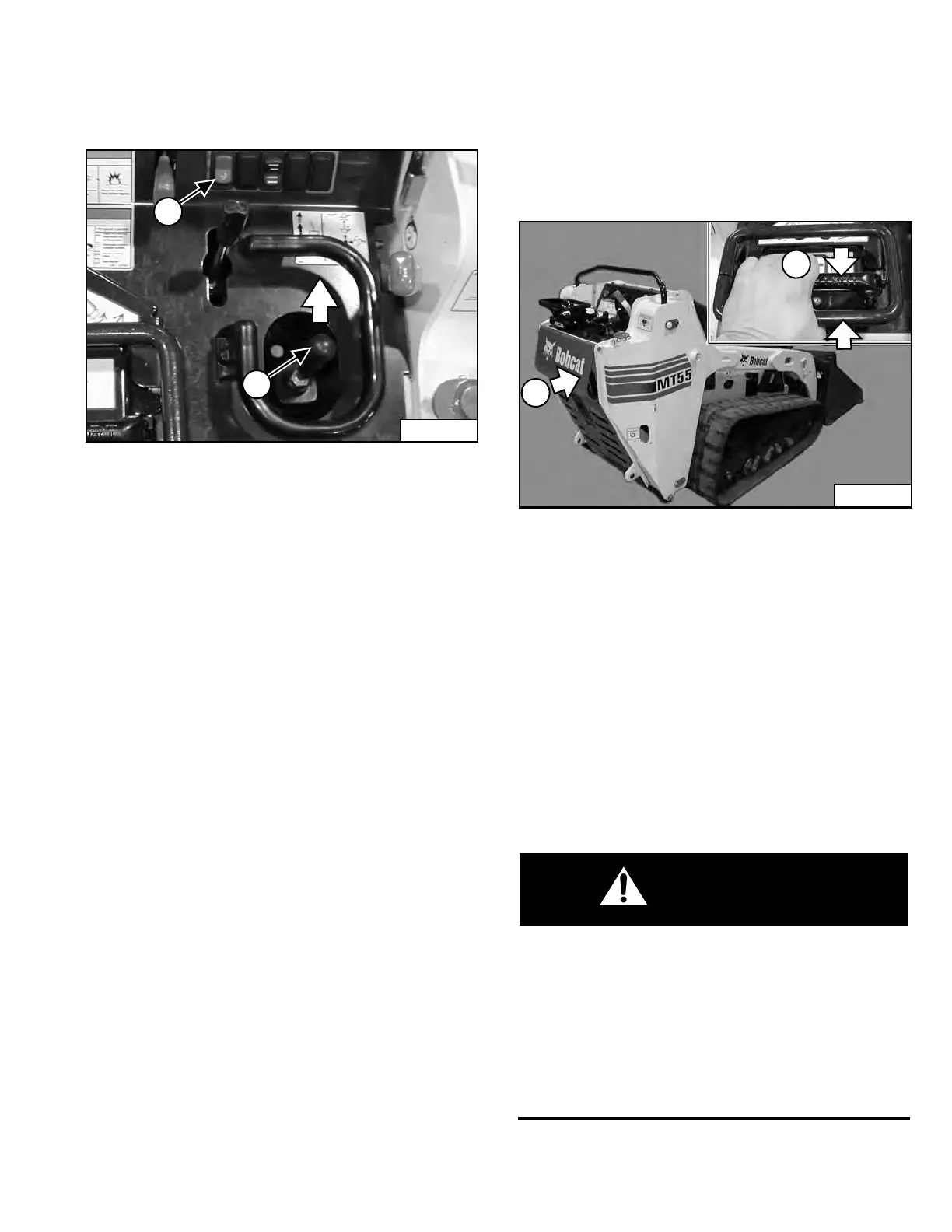

Figure 70

1. Make sure the area around the machine is clear of

bystanders.

2. Start the engine and use one hand to drive the

machine backward (Item 1) [Figure 70].

3. Use your other hand to push the Reverse Stop Panel

forward (Item 2) [Figure 70].

The mini track loader must stop backward movement

when the Reverse Stop Panel is pushed forward.

When the Reverse Stop Panel is fully pressed, the mini

track loader will stop moving in the reverse direction and

will start to move slowly in the forward direction.

If the Reverse Stop Panel does not function correctly, see

your Bobcat Dealer for adjustment.

The Reverse Stop Panel, Neutral Start Interlocks, and

Lift / Tilt Lockouts must function properly.

• The Reverse Stop Panel must stop mini loader

from moving backward when panel is pushed

forward.

• The Lift / Tilt Lockouts must deactivate the lift

and tilt functions when engine is off.

If any of these do not function properly, contact your

dealer for service. DO NOT modify system.

W-2559-0207

Dealer Copy -- Not for Resale

Loading...

Loading...