100-214-276 Rev. 3 4-11

2000X aed Actuator Chapter 4: Installation and Setup

Instruction Manual Installation Requirements

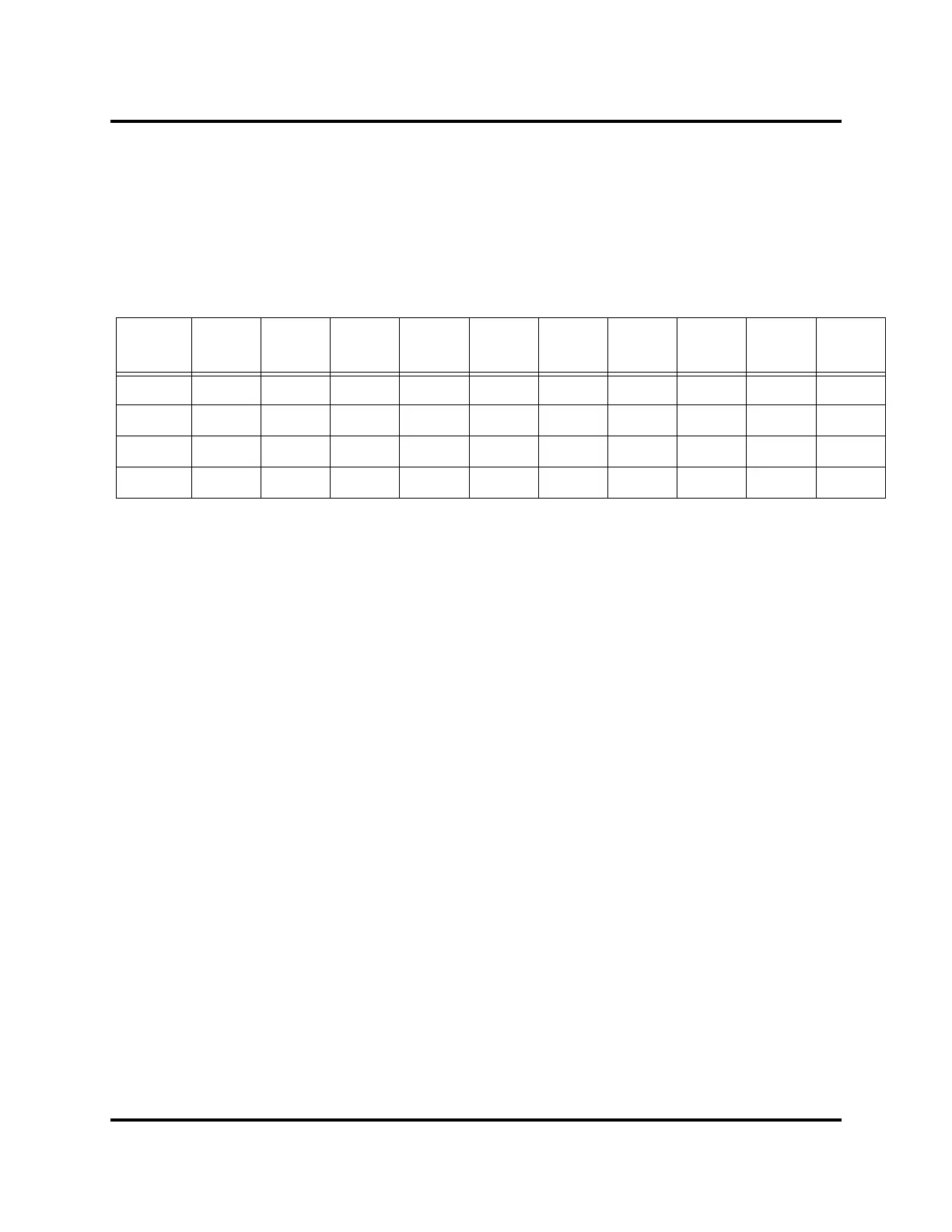

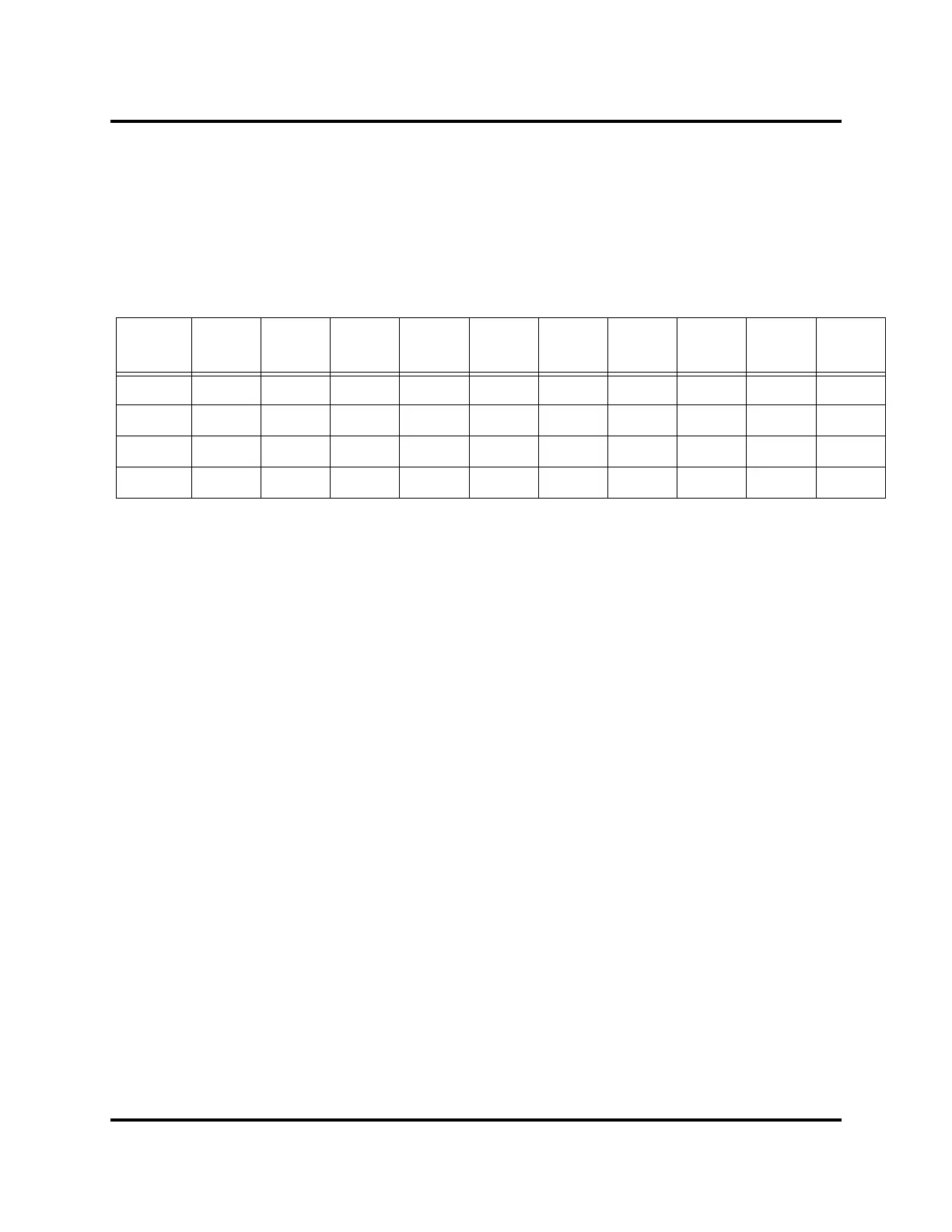

4.4.4 Air Cylinder Consumption

Cubic Feet of air per minute per inch of stroke length (each direction)

Use the table above to calculate the air used by the air cylinder.

Add 0.034 cubic foot per second (2CFM) of actual weld time to account for converter cooling air

per weld cycle.

Example:

3.0" 2000X aed actuator running at full pressure (100psi) and stroke length (4") at a cycle rate of

20 parts per minute = 0.0319 CFM per inch of stroke (from table) x 8" (total strokeis 4" down and

4" back) equals 0.2552 CFM per stroke.

Weld time is 1 second so: 0.034 x 1 = 0.034 CFM for cooling.

Add 0.2552 CFM for cylinder to 0.034 CFM for cooling equals 0.2892 CFM per cycle.

Multiply by 20 (parts per minute) for a total of 5.784 CFM.

The example

above is to be considered a worst case condition for a welder to run at.

The 2000Xf/aef welding system is unique since it’s pneumatics are used in a differential mode of

operation. For this reason, use the 100psi values from the above table to be on the conservative

side for sizing airflow, rather than on the actual force values. Be sure to add the converter cooling

value, 0.034.

Air

Pressure

10 20 30 40 50 60 70 80 90 100

1.5" 0.00174 0.00243 0.00312 0.00381 0.00450 0.00513 0.00590 0.00660 0.00730 0.00800

2" 0.00317 0.00437 0.00557 0.00677 0.00800 0.00930 0.01040 0.01170 0.01300 0.01420

2.5" 0.00490 0.00680 0.00870 0.01060 0.01250 0.01440 0.01630 0.01830 0.02040 0.02230

3" 0.00680 0.00960 0.01240 0.01520 0.01800 0.02080 0.02350 0.02670 0.02910 0.03190

DOC EXPIRES 12PM 7/24/2012. Article or Material must comply with the requirements

stipulated by RoHS in its current version

Loading...

Loading...