6-MAINTENANCE

Tracktension

WARNING

Tip-overhazard!

Onlyraisethetrackaslittleasnecessary.

Failuretocomplycouldresultindeathorseriousinjury.

W0276A

Checkthetracktensionevery50h

NOTICE:ifthetracksaretootight,theywearquickly.Iftracksarenottightenough,theywearquicklyandtheycan

catchonthesprocketwheelorslideofftheidlerwheelorthesprocketwheel.Cleanthetracksafterwork.

Tocheckthetrackstension,proceedasfollows:

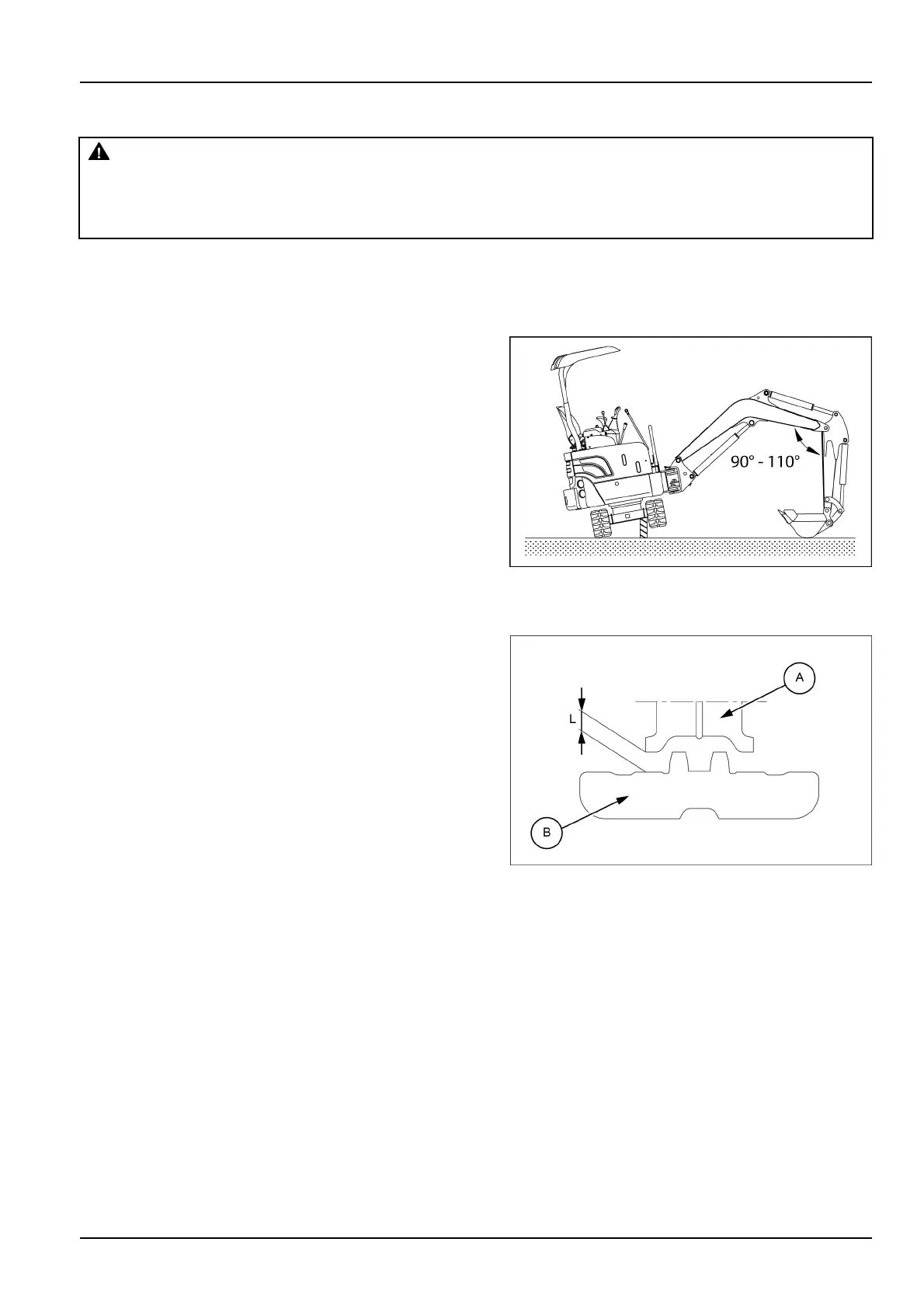

1.Swingtheupperstructureperpendiculartotheun-

dercarriage.Lowertheattachmenttotheground,

thenlowertheboomuntilthetrackisraisedoffthe

ground.Placeablockundertheundercarriageand

raisetheattachmentofftheground.

2.Settheenginespeedlevertothemaximumspeed

position.

3.Operatethetravelcontrollevertomovetheraised

trackforwardandbackwardandshakeoffthemud.

4.Repeatthesameoperationsfortheothertrack.

SMIL16MEX2515AA1

Checkingthetension

1.Stoptheengine,thenremovethekeyfromthe

starterswitch.

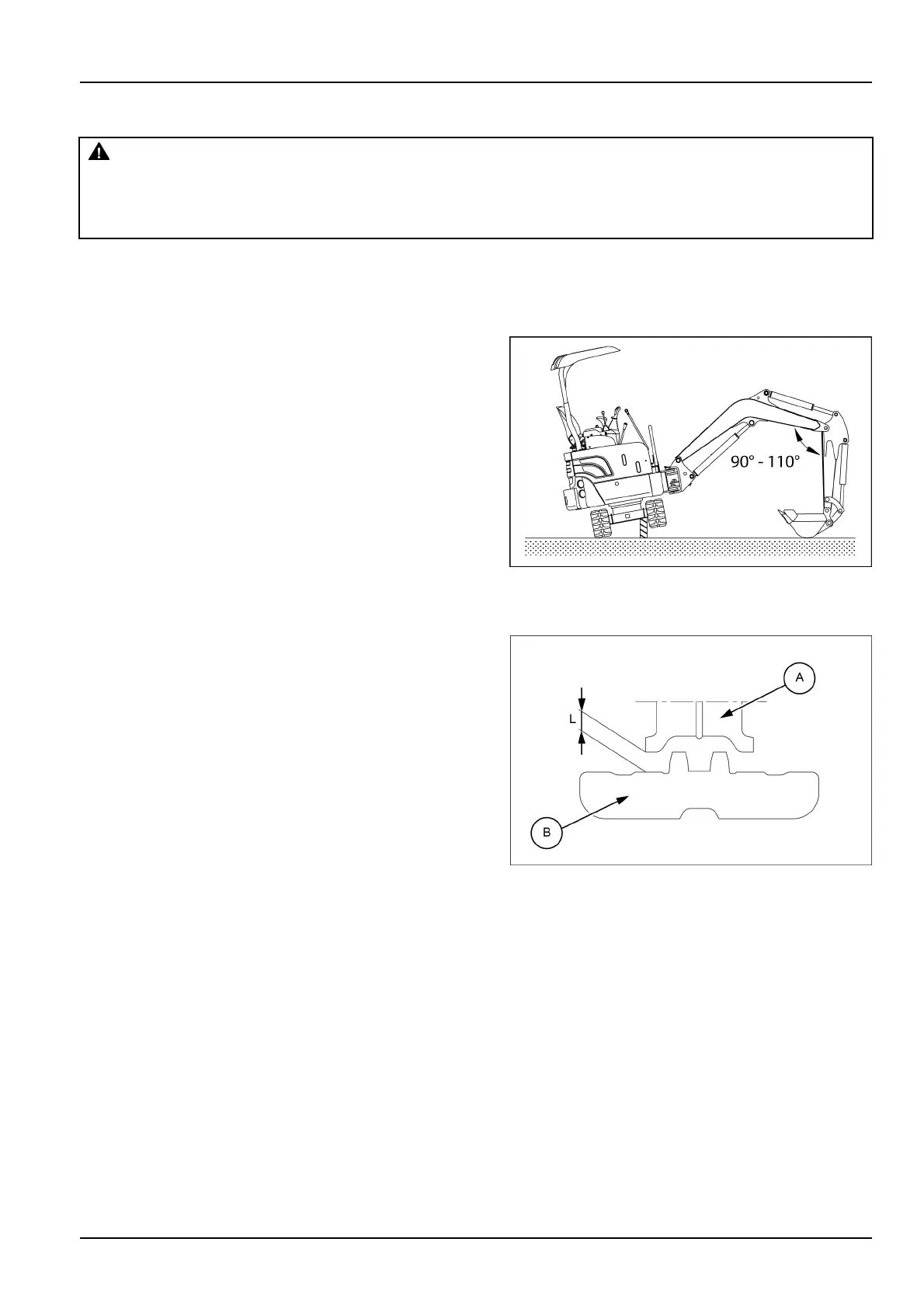

2.Atthecenterofthetrack,measuretheslack(L)

betweenthebottomofthelowerroller(A)andthe

rubbertrackshoe(B).

SMIL16MEX0423AB2

3.Thevalueoftheslackmustbewithin5–10mm

(0.2–0.4in).

4.Adjustthetensionasnecessary,thenlowerthe

tracktotheground.

5.Repeatthesameoperationsfortheothertrack.

Adjustingthetension

Toincreasethetension:

1.Cleanthegreasettingadapterandthegrease

tting.

2.Connectthegreasepump.Injectthegreaseto

obtaintherightamountoftracktension.

3.Removethegreasepumpandcleanthegrease

tting.

4.Repeatthesameoperationsfortheothertrack.

6-29

Loading...

Loading...