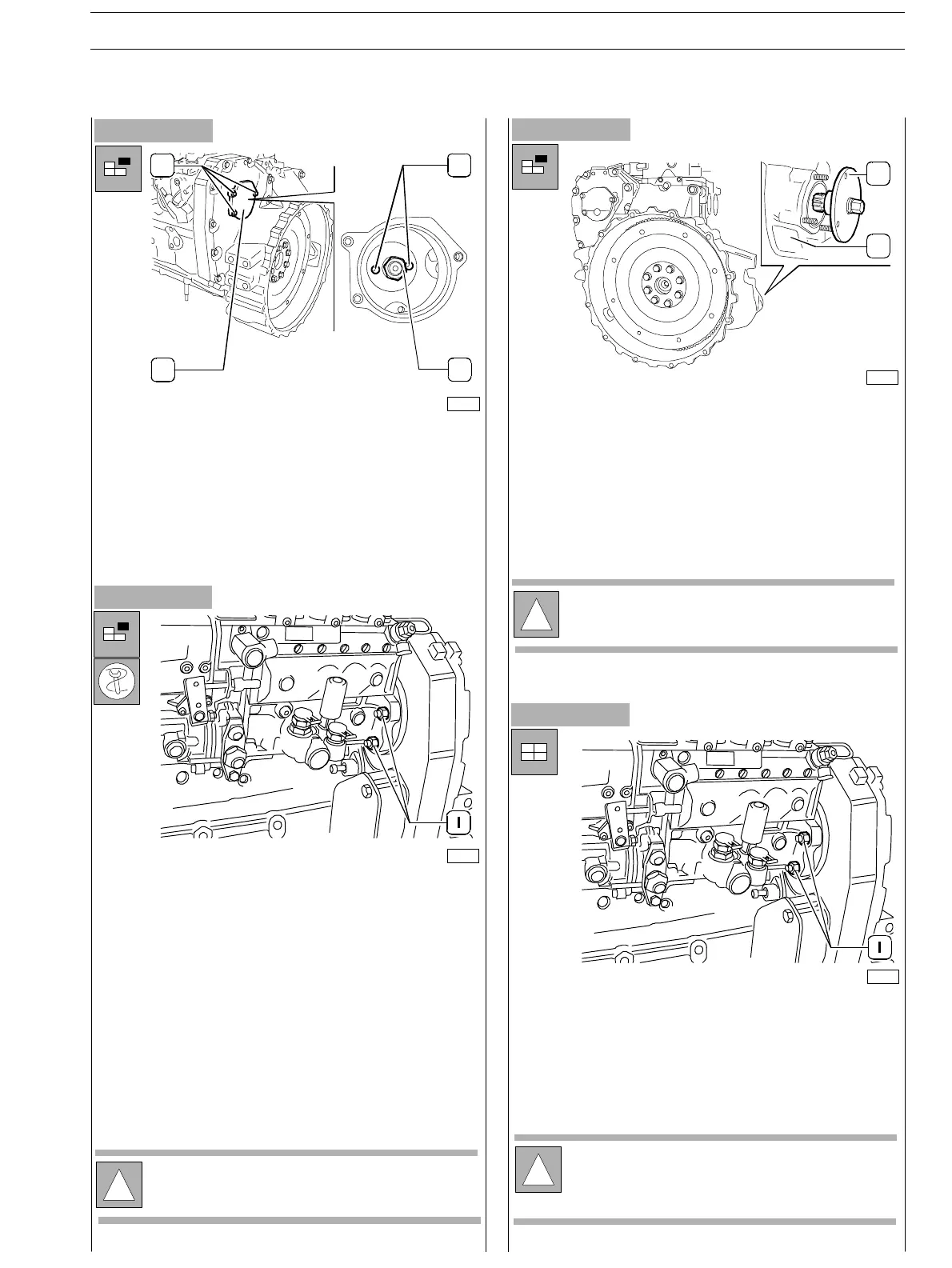

Figure 206

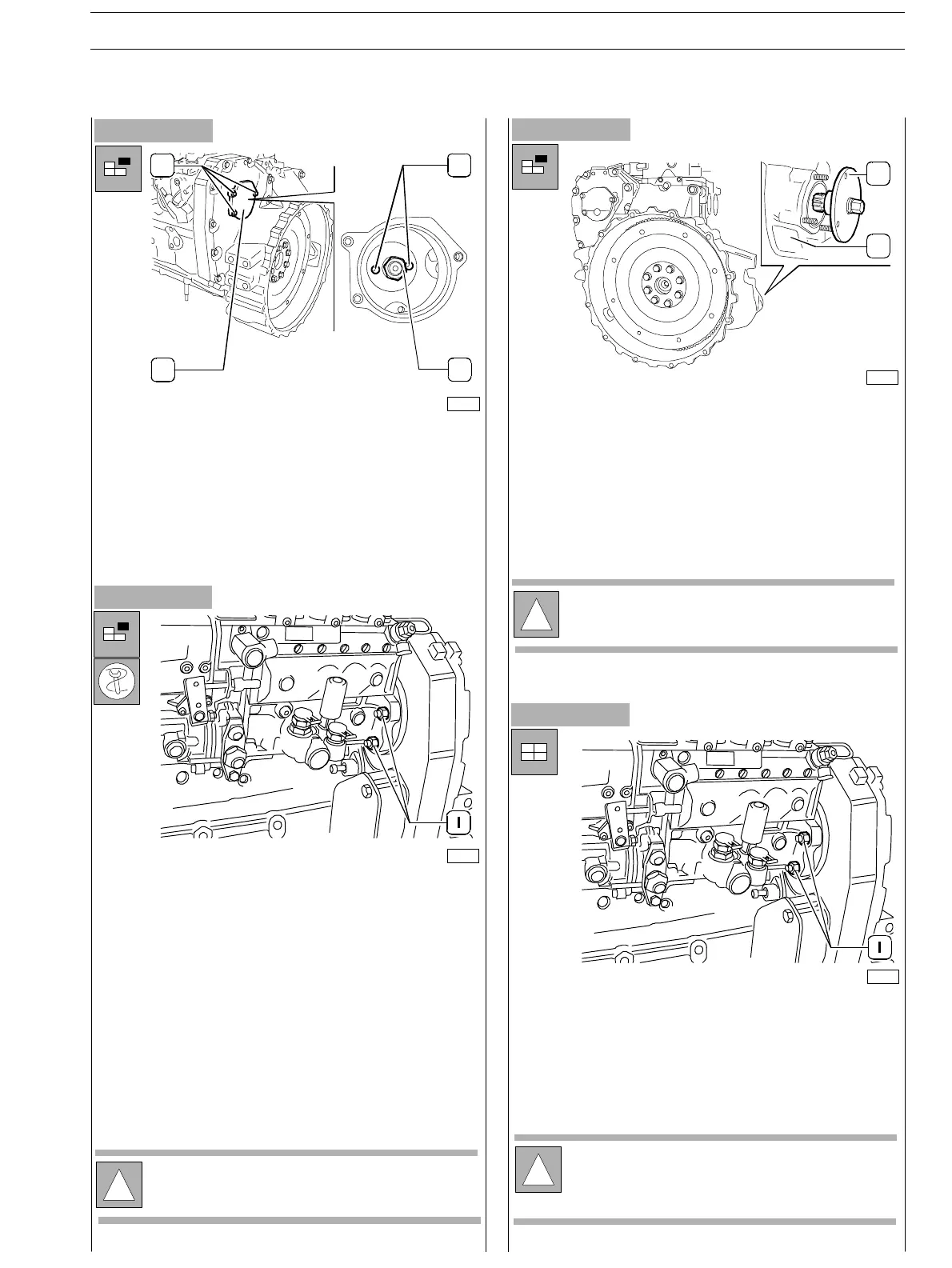

Figure 207

- From the pump side, loosen the fixing nuts (1) without

removing them in order to enable moving the pump

backwards using 380000979 extractor.

-

Assemble the 380000979 extractor throughout the two

threaded ports (4, Figure 206) and withdraw the gear

from the pump shaft.

-

Hold the feed pump using acceptable tools and unscrew

completely the fixing nuts.

- Withdraw the pump from the holding studs together

with the gasket.

Figure 208

- From timing side, remove the cover (2) loosening the

screws (1) in order to have access to the union fixing nut

(3) to the pump driving gear.

- Loosen the fixing nut (3) and remove the relating washer.

When assembling the feed pump to the engine, it is n ecessary

to meet the P.M.S. requirements for the N.I. cylinder.

-

Use the 380000988 tool (2) on the flywheel box (I)

to car ry out flywheel rotation and operate using the pin

as previously described.

Figure 209

!

Hold the pump driving gear to avoid interference or

cr awling during timing gear rotation.

1

23

4

75693

76133

75714

1

2

76133

!

In these conditionsthe pump is pre−set and can be

assembled to the engine further.

-

Hold the feed pump using acceptable tools and assemble

it (pre set pump) to the engine in its housing: insert the

camshaft capule into the port of the pump’s driving gear

(not provided with key).

- Tighten the fixing nuts (1) centering and locking the

pump’s flange within the slot.

!

The gasket removed during pump disassembly shall

not be utilised again.

Always use original spare parts.

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

67

ED. FEBUARY 2003

zs

Loading...

Loading...