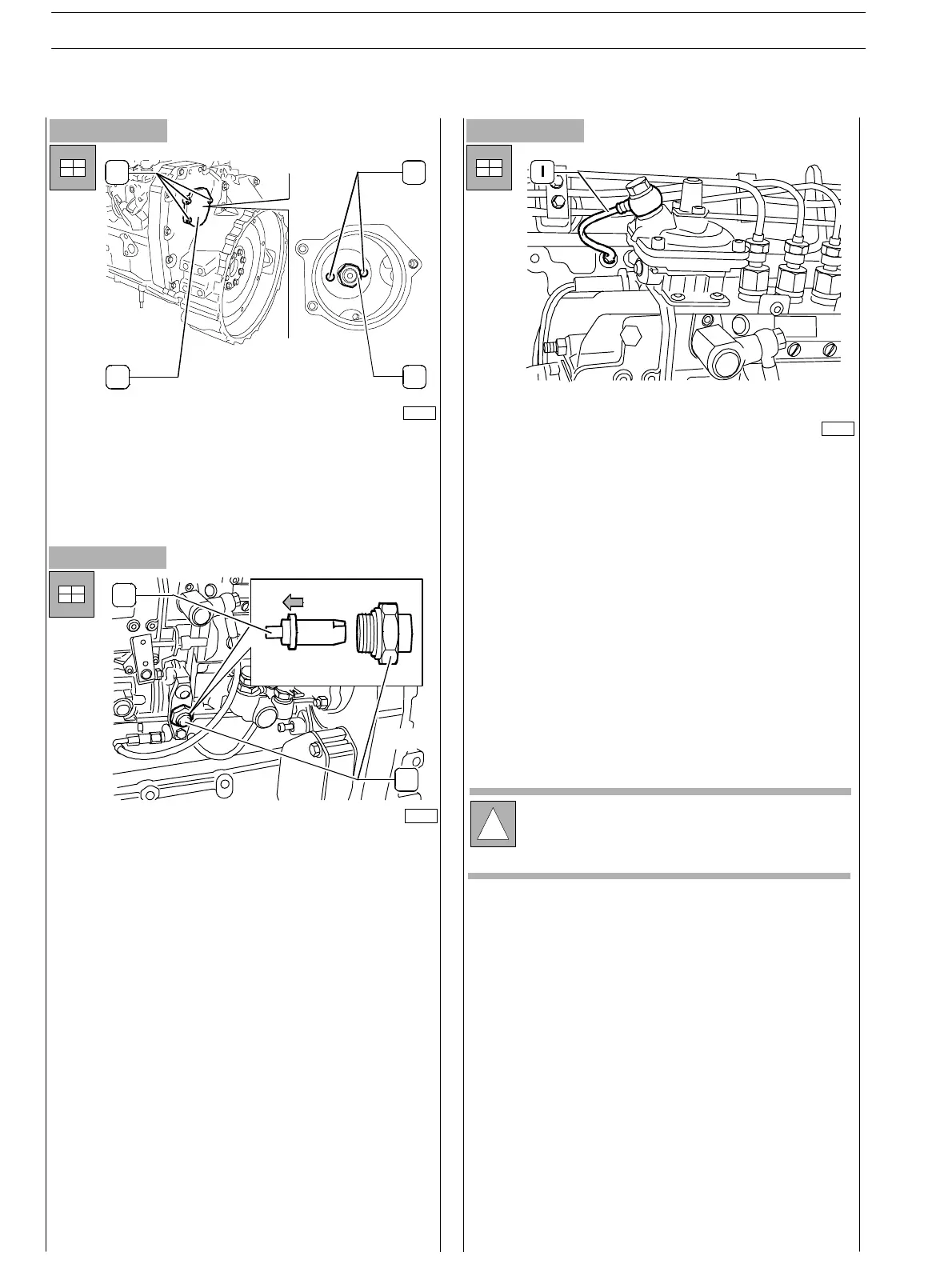

Figure 210

- Assemble the cover (2, Figure 210) including gasket and

tighten the screws (1,Figure210).

- Pull the pin outwards setting the camshaft gear free.

-

Remove the 380000988 tool locking flywheel rotation;

place the starter in its housing.

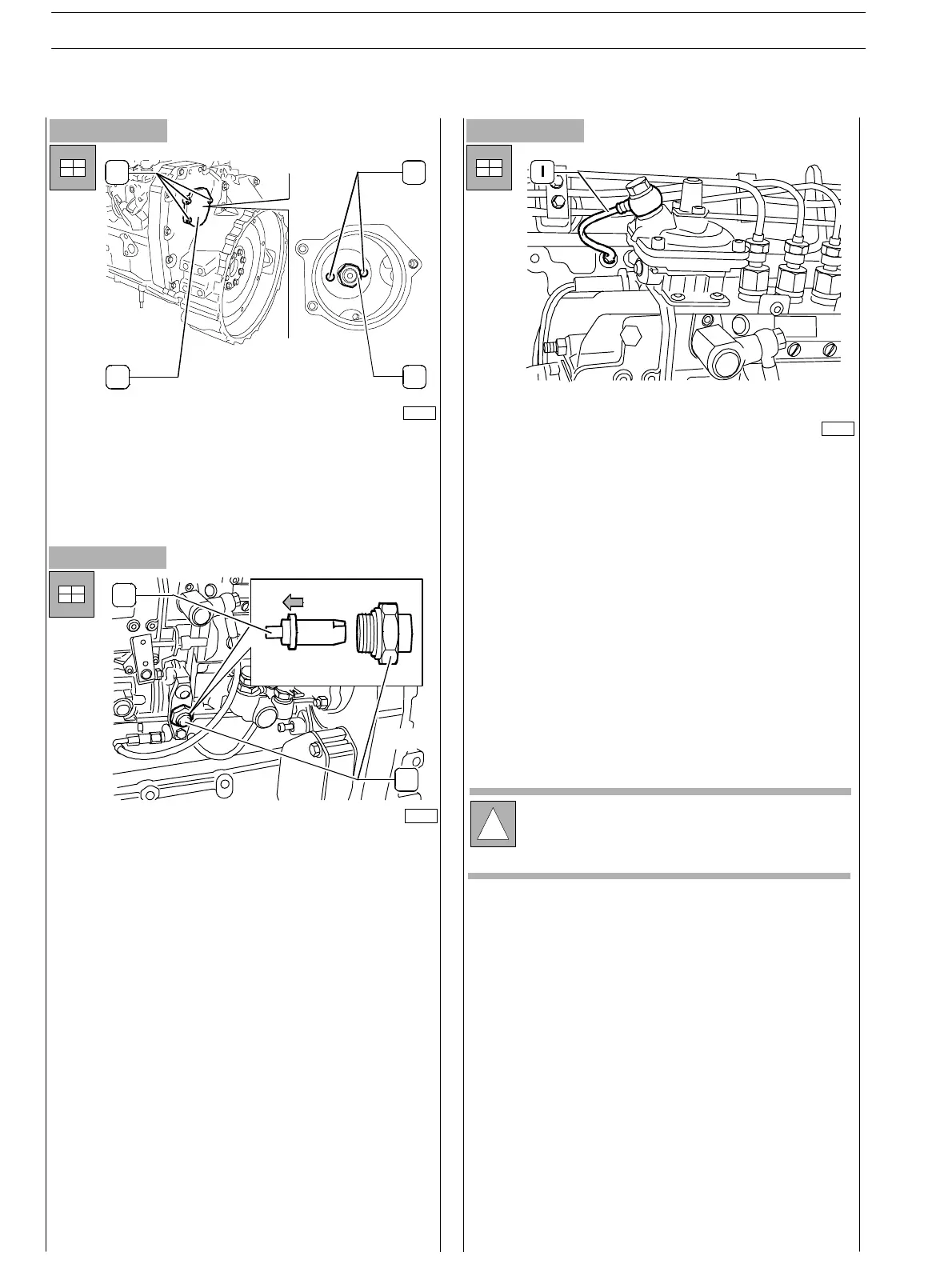

- Connect all pipelines (from pumping elements to

injectors, bleeding recovery pipes from in jec t ors to

pump, LDA pipeline (1) and feed provided by priming

pump and lubrication pipelines).

- Connect electrical switch devices to engine stop.

Figure 211

Figure 212

1

23

4

75715

- On th e timing side, throughout the specially appointed

port, fit the washer and screw up the fixing nut (3) to the

pump shaft. Lock the nut to the 90−95 Nm c o uple.

!

In case pump removal has been carried out while the

engine was assembled, connect acceleration cable.

76134

- Remove th e hexagon shaped cap (1) from the speed

gauge box and with draw locking pin (2) from the

camshaft.

- Tur n th e locking pin (2) upsidedown an d place it in its

housing: this operation enables free rotation of the

pump’ s camshaft.

- Assemble the hexagon shaped cap (1) to the speed

gauge box.

76139

1

2

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

68

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...