Figure 71

Figure 72

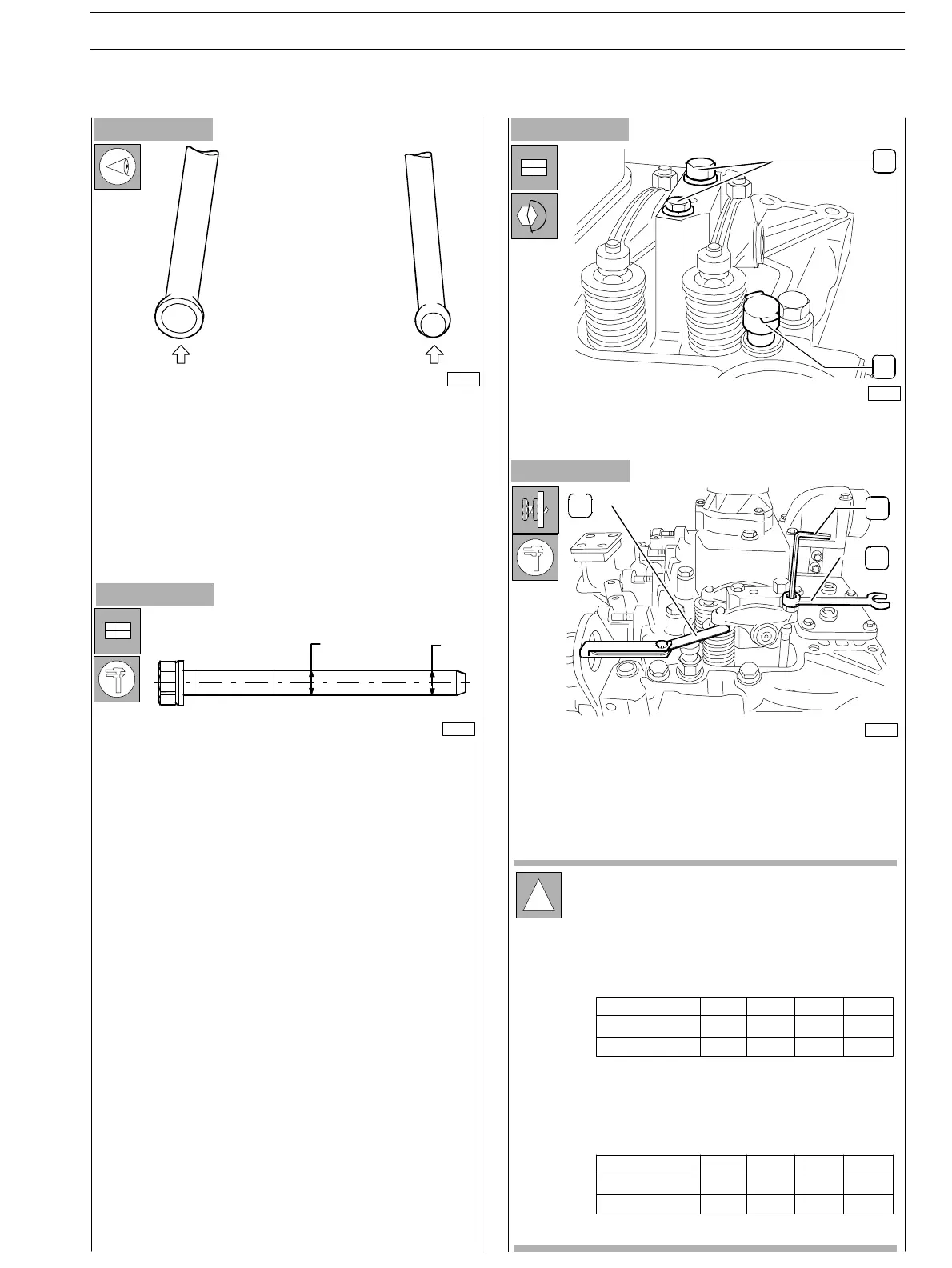

- Tighten the screws (2) to the prescribed couple and

assemble water temperature sen sor (1).

!

In order carry out a quicker adjustment of the

working slack between rocker arms and valves,

proceed as following:

Rotate the engine drive shaft, balance the valves of

cylin der 1 and adjust the valves identified by star

symbol, as indicated in the following table:

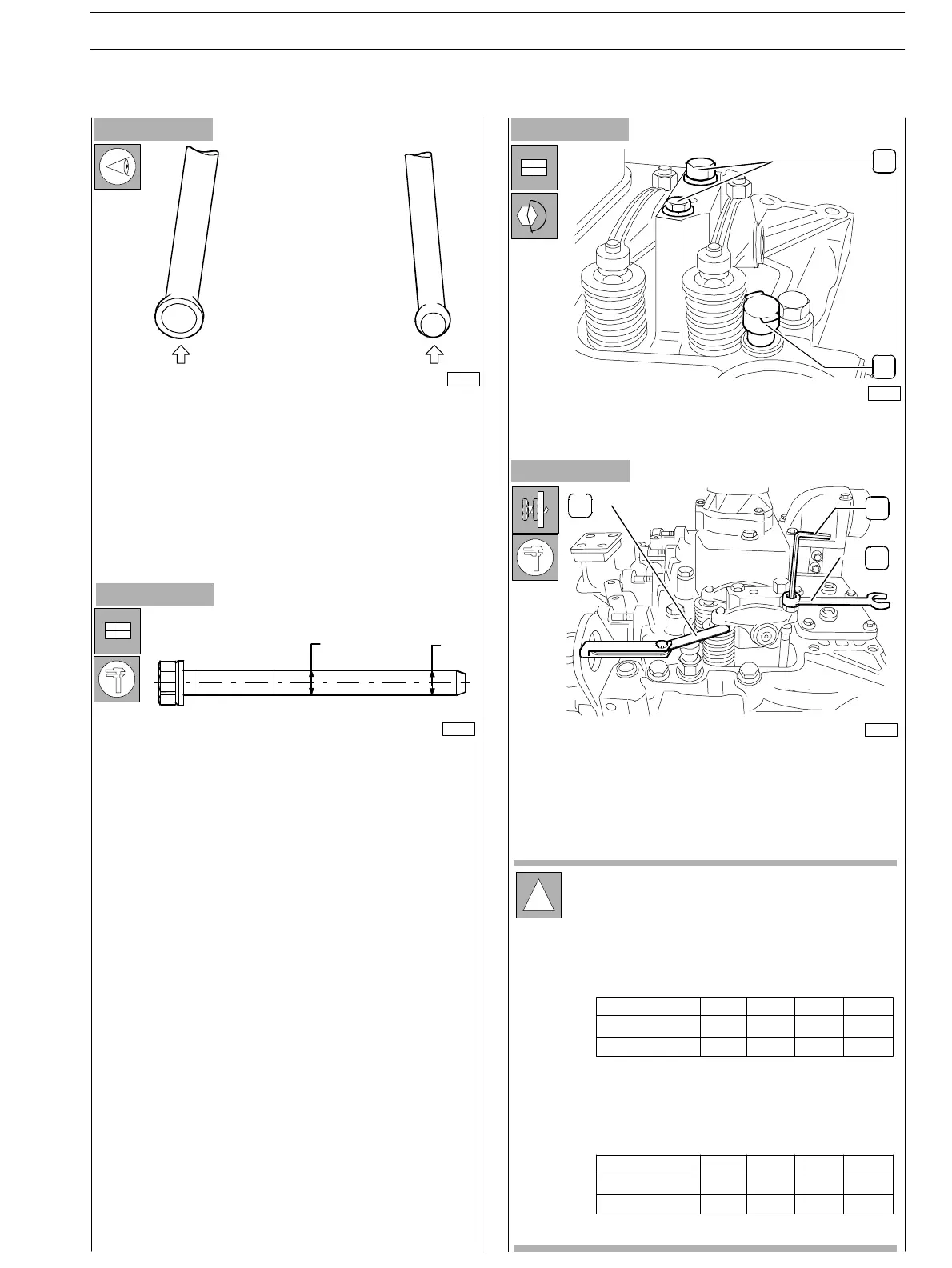

Before executing assembly, check the Rocker Arm driving

rods: these shall not be deformed; the spherical ends in

contact with the Rocker Arm adjustment screw and with the

tappet (arrows) shall not present evidence of seizure or

wear: in case of detection proceed replacing them.

The rods driving the suction and exhau st valves are identical

and therefore interchangeable.

Figure 73

Adjust the slack between rocker arms and valves using socket

wrench (1), point wren ch (3) and feeler gauge (2).

Correct working slack is:

− suction valves 0.30 0.05 mm

− exhaust valves 0.55 0.05 mm.

Figure 74

32655

D1D2

75703

- Insert the tappet driving rods and the Rocker Arm unit.

Before usin g the fixing screws again, measure them twice

as indicated in the picture, checking D1 and D2

diameters:

if D1 − D2 < 0,1 mm the screw can be utilised again;

if D1 − D2 > 0,1 mm the screw must be replaced;

1

2

75683

75806

2

1

3

Cylinder n°

Suction

Exhaust

1

234

−

*

**

*

−

−−

Cylinder n

Suction

Exhaust

1

234

−

*

**

*

−

−

−

Rotate th e engine drive shaft of 360 deg., balance the

valves of cy linder 4 and adjust the valves identified by

star sy mbol, as indicated in the following table:

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

27

ED. FEBUARY 2003

Loading...

Loading...