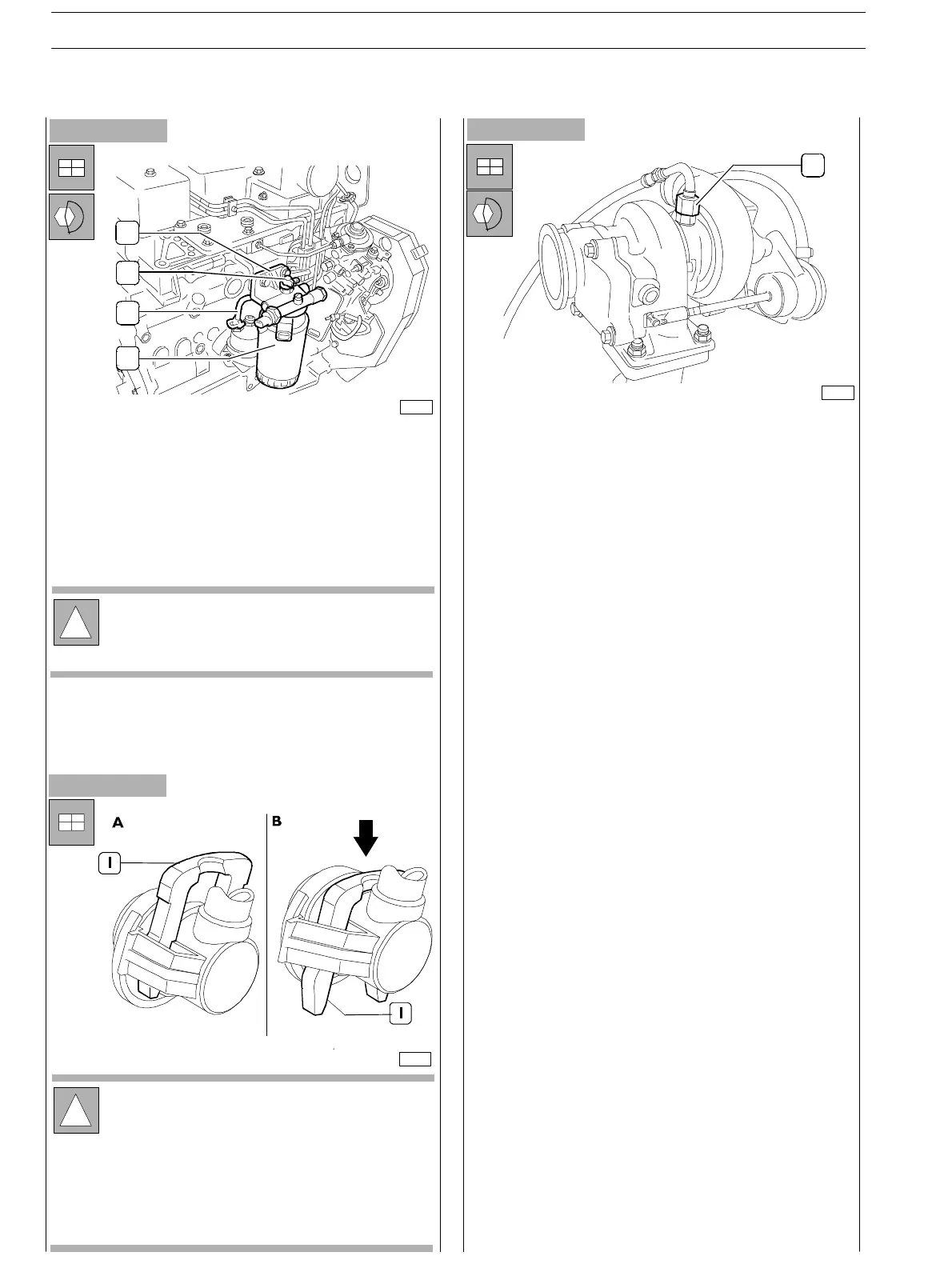

Figure 87

- Assemble the fuel filter bearin g (4) to the bracket fixed

to the engine head.

- Conn ec t the fuel pipelines (2 and 3) respectively from

priming pump to filter bearin g and from this last one to

feed pump.

-

Using acceptable tools assemble fuel filter (I).

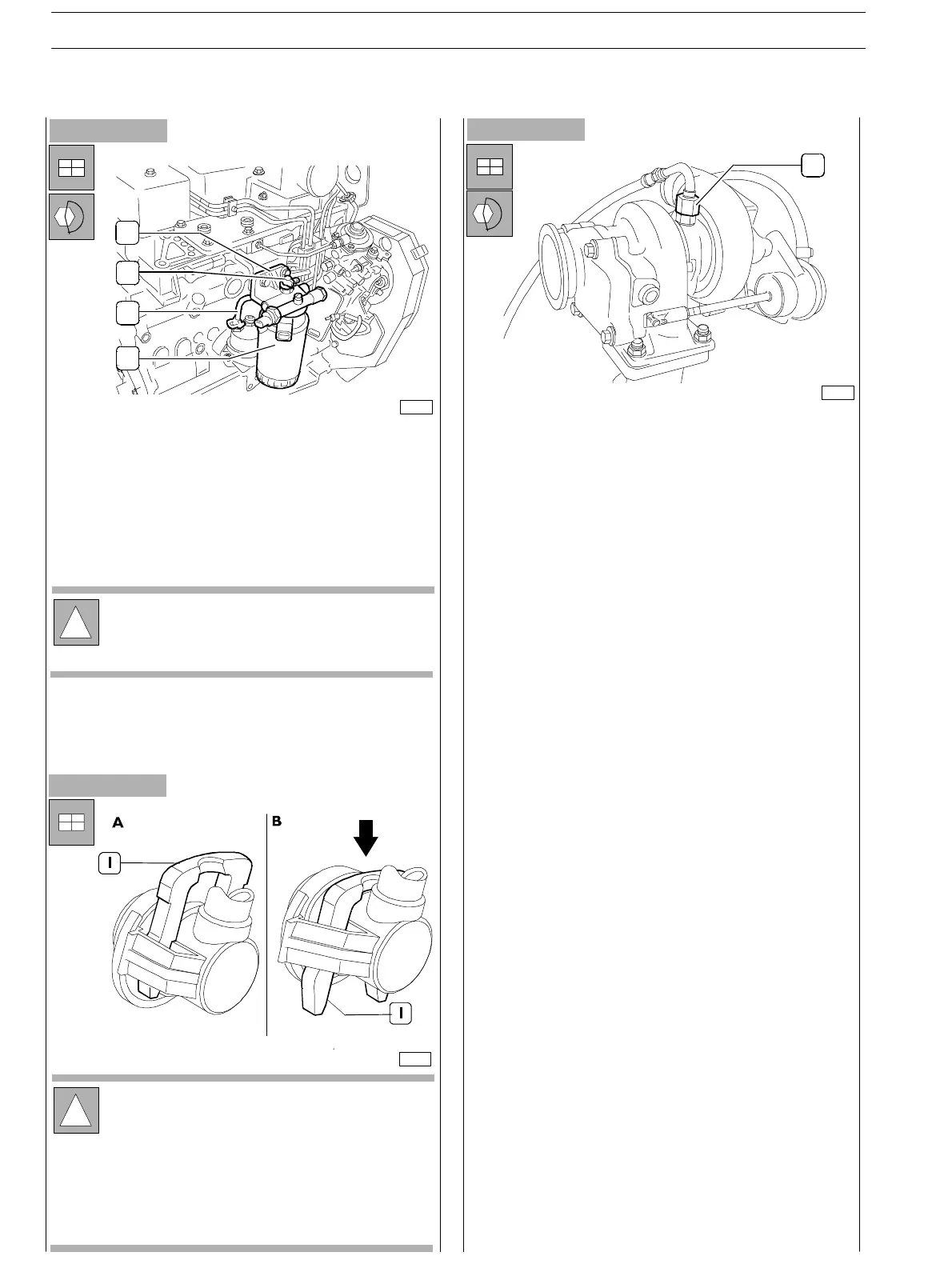

Figure 88

Proceed assembling the turbocharger :

- Hold the turbochar ger and place it on th e exhaust

manifold after having interposed the gasket.

- Screw up the fixing nuts of the turbocharger to the

exhaust manifold tightening them to the prescribed

couple.

- Tighten the lubrication pipe fixing rin g. O per ate in t he

same way on the other end of the pipe. Connect it to

the upper part of the heat exchanger.

To complete engine assembly it is necessary to remove it

from the turning stand.

-

Using acceptable tools, hold the engine and loosen

the screws fixing the brackets to the turning stand.

- Disassemble the br ackets from the engine after having

properly put it on a wooden bearing.

Figure 89

!

The filter shall be priory filled with fuel t o facilitate

feed system b leed operations.

1

2

3

4

75676

70126

!

To connect fuel pipelines (2 and 3, Figure 87) in low

pressure from the relating connection unions it is

necessary to press the locking fastener (1) as shown

in picture B.

After having connected the pipeline, reset the

fastener (1) into block position as shown in picture

A.

75675

1

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

32

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...