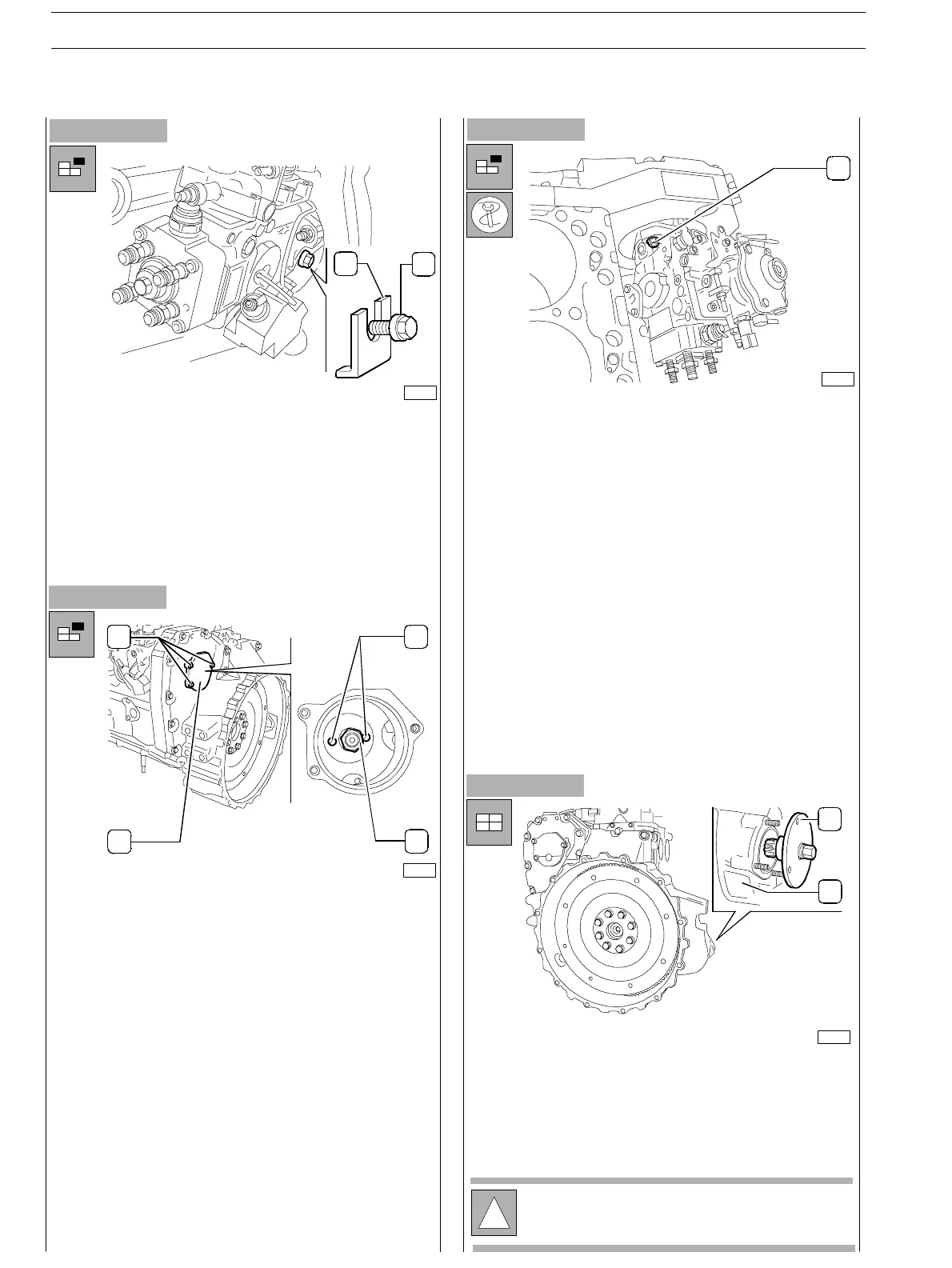

Figure 96

- Part ially loosen the lateral sc rew (2) loc king the pump

shaft and remove the slip washer (2). Absolutely keep

the slip wash er (it is recommended to fix it with stripe

or wire to the pump).

- Tighten the lateral screw (1) blocking rotation of the

pump shaft.

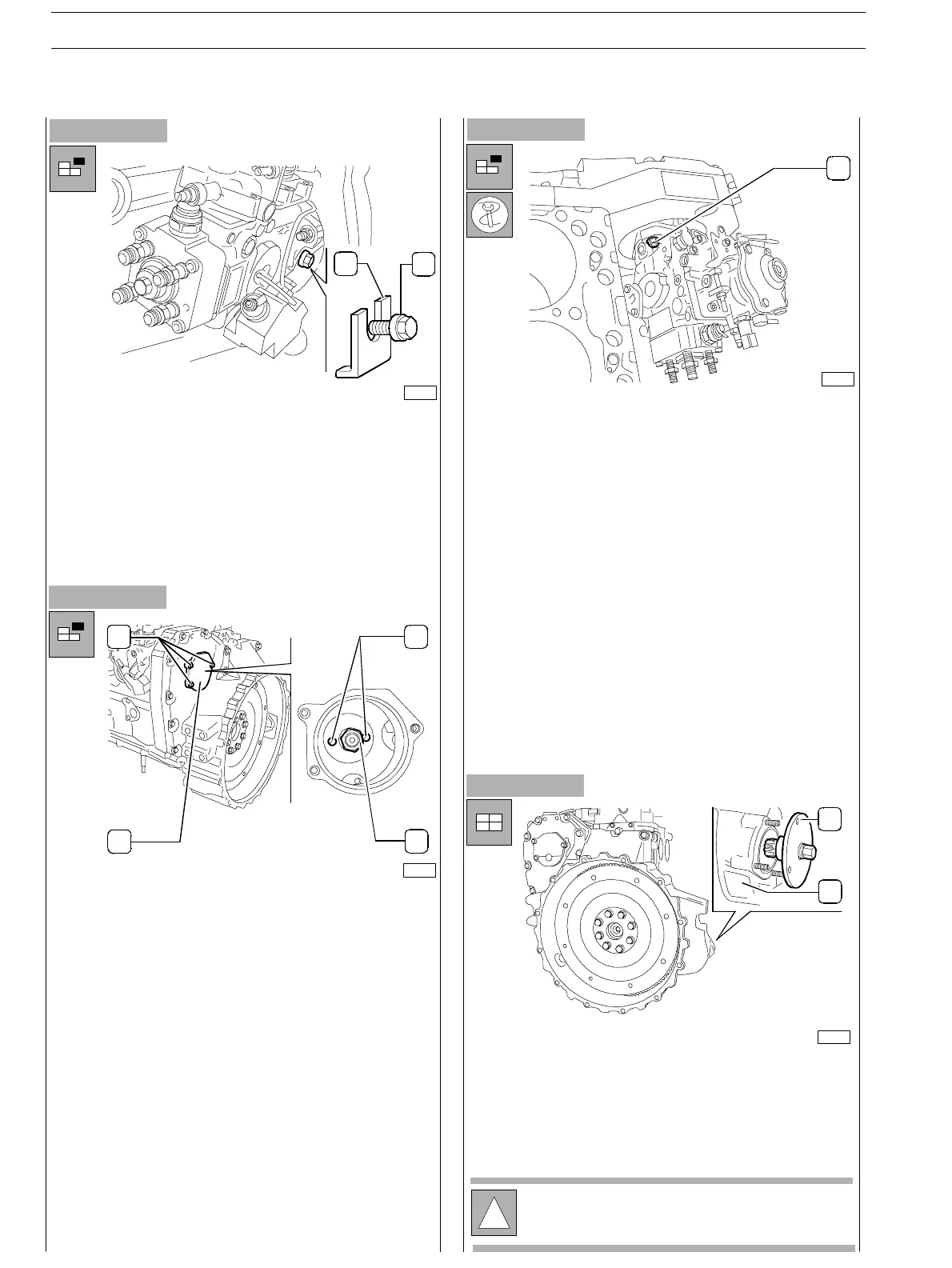

Figure 97

- From the pump side, loosen the fixing nuts (1) without

removing them in order to enable moving the pump

backwards using 380000979 extractor.

-

Assemble the 380000979 extractor throughout the two

threaded ports (4, Figure 97) and wit hdraw the gear

from the pump shaft.

- Proper ly h old the feed pump and loosen c ompletely the

fixing nuts.

- Withdraw the pump from the studs, together with the

gasket.

Figure 98

- From timing side, remove the cover (2) loosening the

screws (1) in order to have access to the union fixing nut

(3) to the pump driving gear.

- Loosen the fixing nut (3) and remove the relating washer.

When assembling the feed pump to the engine, it is n ecessary

to meet the P.M.S. requirements for the N.I. cylinder.

-

Use the 380000988 tool (2) on the flywheel box (I)

to car ry out flywheel rotation and operate using the pin

as previously described.

Figure 99

!

Hold the pump driving gear to avoid interference or

cr awling during timing gear rotation.

75721

2

1

1

23

4

75693

1

75694

75714

1

2

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

36

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...