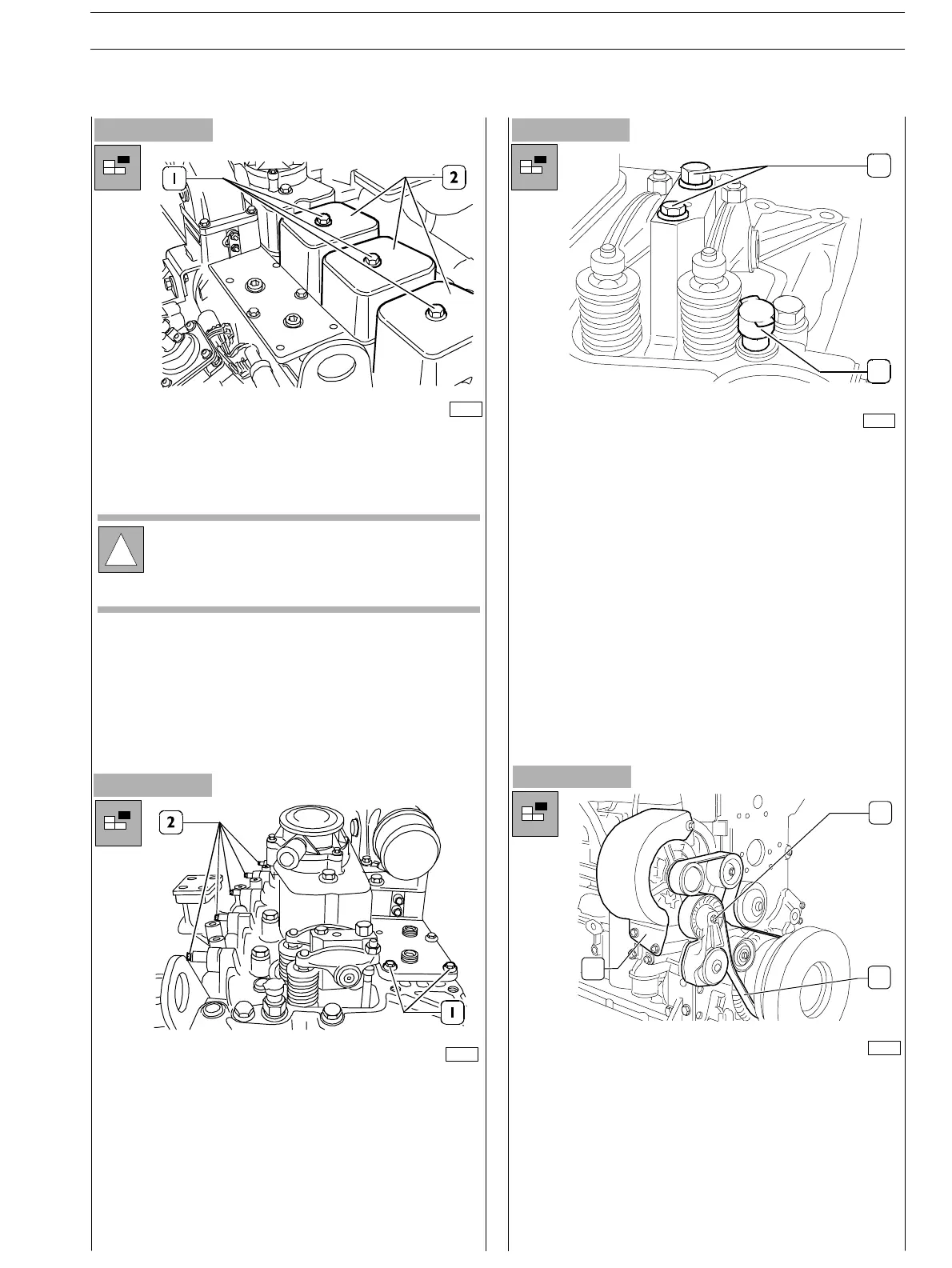

Figure 119

Figure 120

- Remove tappet caps:

Loosen the fixing screws (1) an d lift the caps (2);

remove the gaskets.

- Disassemble suction and exhaust manifolds: loosen the

screws (1) fixing t h e suction manifold plate to the

cylinder head (some of them have already been

screwed−out sinc e fixing the pipe brackets to th e

injectors); from the exhaust manifold side loosen the

eight (2) fixing screws; remove t he gasket s .

- Disassemble rocker arm bearings; loosen the two fixing

screws (2) and remove the complete rocker arm bearing;

withdraw tappet rods. Repeat the operation for all the

remaining roc ker ar m bearings.

- Disassemble water temperature transmitter (1).

!

On the central cap there is a blow−by valve for the

lubrication oil vapours.

All the gaskets shall always be replaced durin g

assembly.

76149

76151

Figure 121

75683

1

2

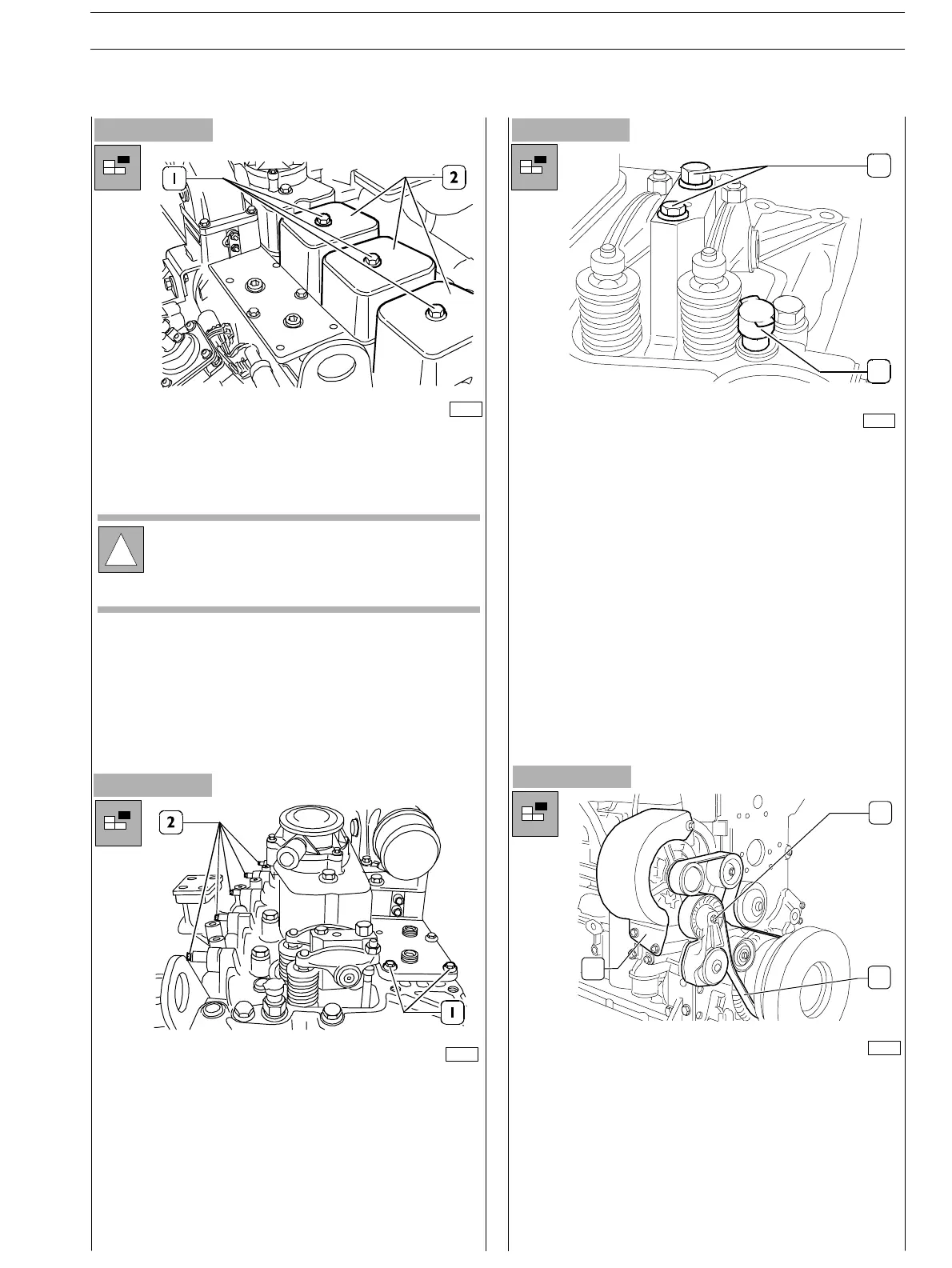

Figure 122

74171

- Unloose the screws fixing the alternator’s protection to

thesupportandremoveit.

- Workon the drive belt tensor (1) and extract the belt (3)

from the belt pulleys, from the water pump ones and

from the belt rebound pulleys.

- Disassemble the belt tensor.

- Unloose the screw fixing the alternator to the upper

bracket.

2

3

1

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

43

ED. FEBUARY 2003

zs

Loading...

Loading...