SECTION 58 -- ATTACHMENTS AND HEADERS -- CHAPTER 2

58-23

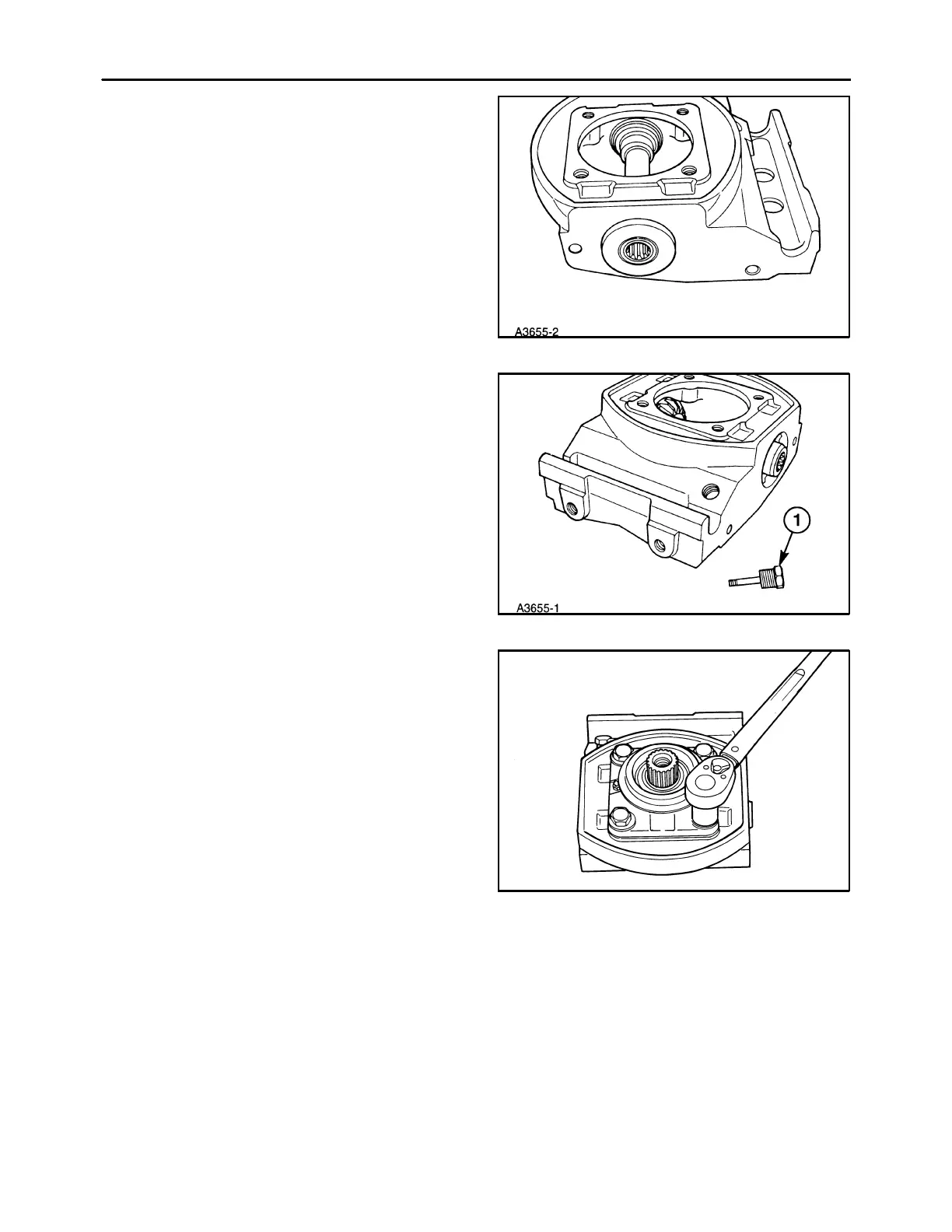

6. Apply grease to the sealing lip on the shaft seal,

and press them into place on each side of the

housing.

NOTE: The seal must be pressed into place with a

seal installing tool or suitable substitute. The seals

must be flush with the side of the housing, and square

to the shaft. If the seal is driven in with a hammer, it

will be distorted and leak, causing disc module

failure.

50

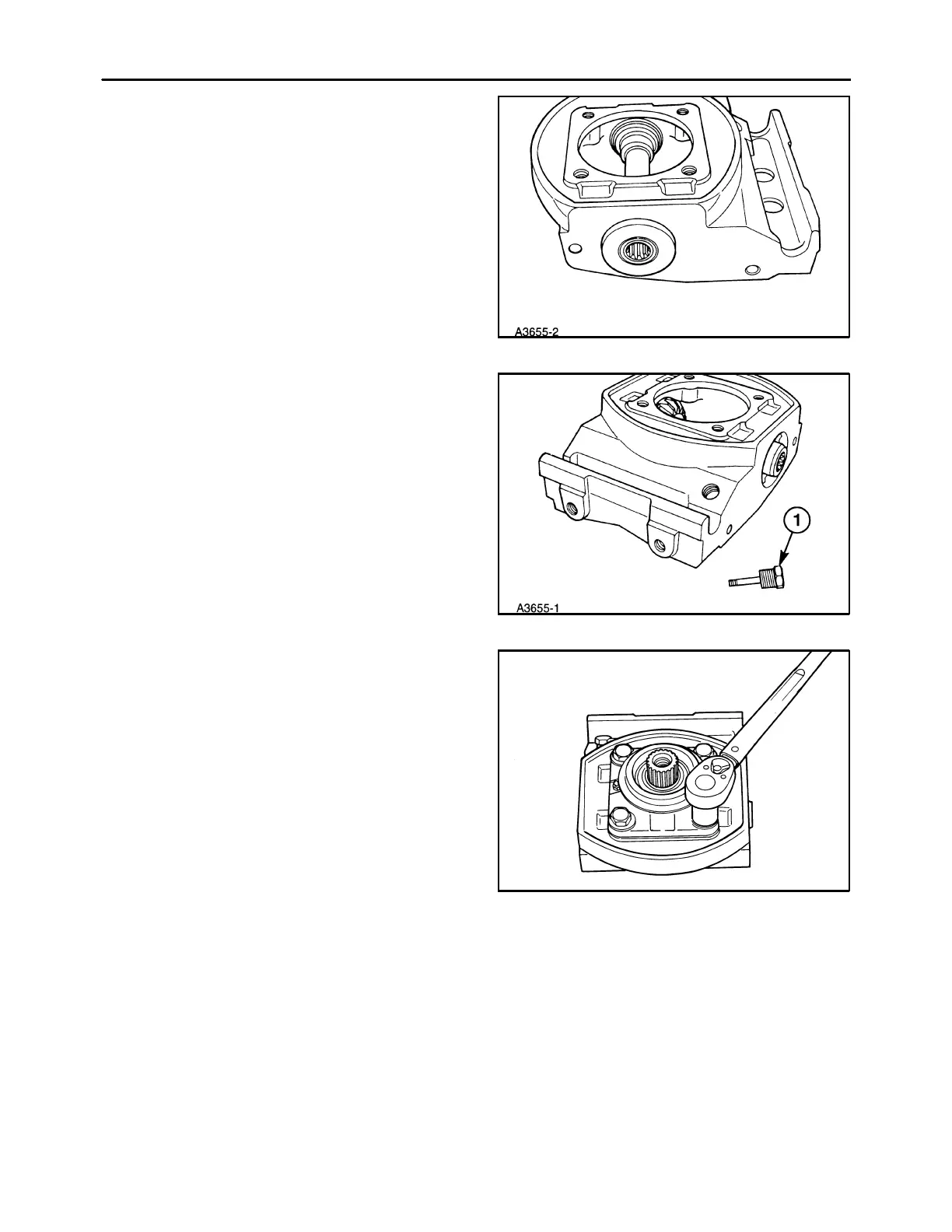

7. Apply silicone sealant to the threads of the drain

plug and check plug, and install them into the

housing. Pour 300 ml of API GL5 80W90 gear oil

through the top opening into the lower module.

51

8. Apply a thin bead of silicone sealant to the seal-

ing flange of the new top cap assembly, and posi-

tion it on the lower module assembly with the

breather facing to the right. Apply silicone sealant

to the end of the threads of the top cap retaining

bolts, install them and torque to 83 ft lbs (113

N⋅m).

Do not install the disc hub onto the top cap at this

time, unless it is desired to check backlash. To

check backlash, the disc hub must be installed

and torqued to 150 ft. lbs. (224 N⋅m) to seat bevel

shaft against bearings and housing.

Acceptable backlash is 0.005″ to 0.011″. If back-

lash is unacceptable, recheck assembly of the

disc module.

19985741

52

Loading...

Loading...