SECTION 58 -- ATTACHMENTS AND HEADERS -- CHAPTER 2

58-32

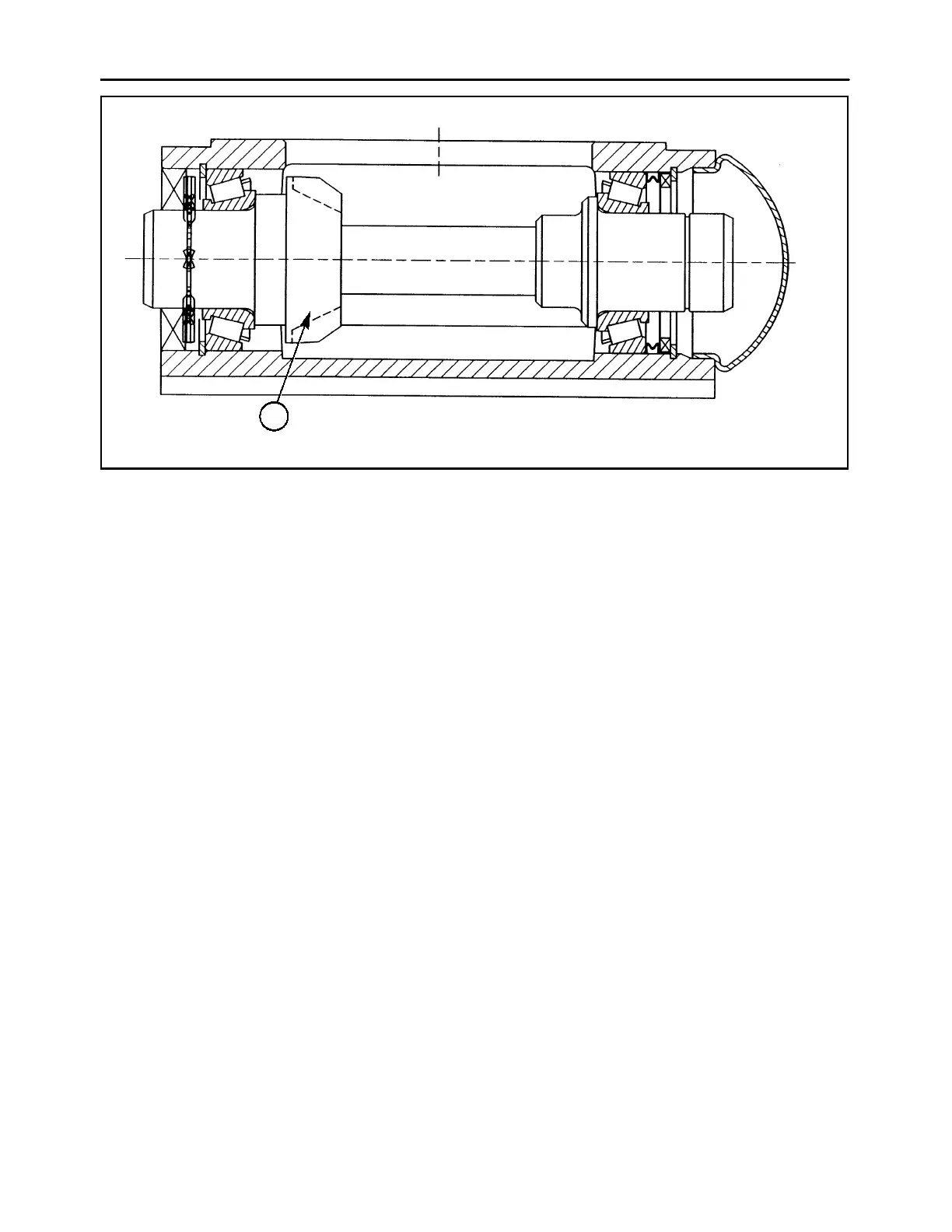

CUTAWAY VIEW FROM FRONT OF MODULE

1

75

DRIVE MODULE - ASSEMBLY

The drive module must be assembled with the pinion

gear, 1, positioned to the right side of the housing, as

viewed from the rear, in order to ensure the cutter bar

is driven in the correct direction. The drive module is

serviced using the same lower pinion kit as the disc

modules; all parts are fully interchangeable, but the

drive module does not use a slinger or seal on the left

end of the pinion shaft.

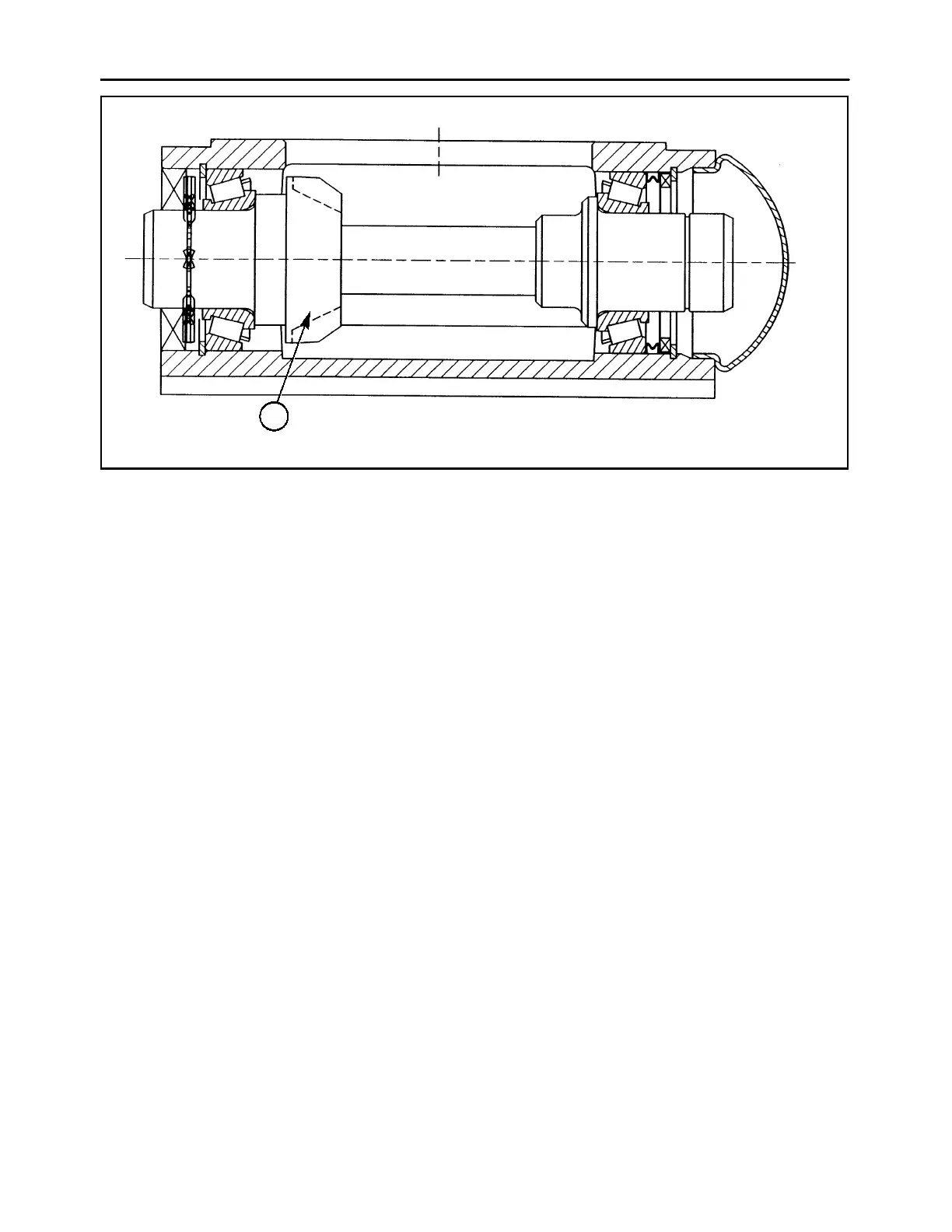

The backlash between the pinion gear and the bevel

gear on the output shaft of the bevel gearbox is con-

trolled by the precision machining of the drive module

and bevel gearbox housings, the use of precision

forged gears, and the use of low tolerance bearings,

which are manufactured to provide a specific “stack

height”, or combined thickness. It is not necessary to

check the backlash of the gearset after the bevel

gearbox is reassembled onto the drive module.

NOTE: The low tolerance bearings are manufac-

tured for a specific “stack height”. Do not mix old and

new bearing components or substitute with “jobber”

bearings.

Loading...

Loading...