SECTION 58 -- ATTACHMENTS AND HEADERS -- CHAPTER 2

58-2

INTRODUCTION

The MDX71 disc mower uses a 5 disc cutter bar to

provide a 6′ 8″ width of cut.

The MDX81 disc mower ses a 6 disc cutter bar to pro-

videa7′ 10″ width of cut.

The MDX91 disc mower uses a 7 disc cutter bar to

provide a 9′ 2″ width of cut.

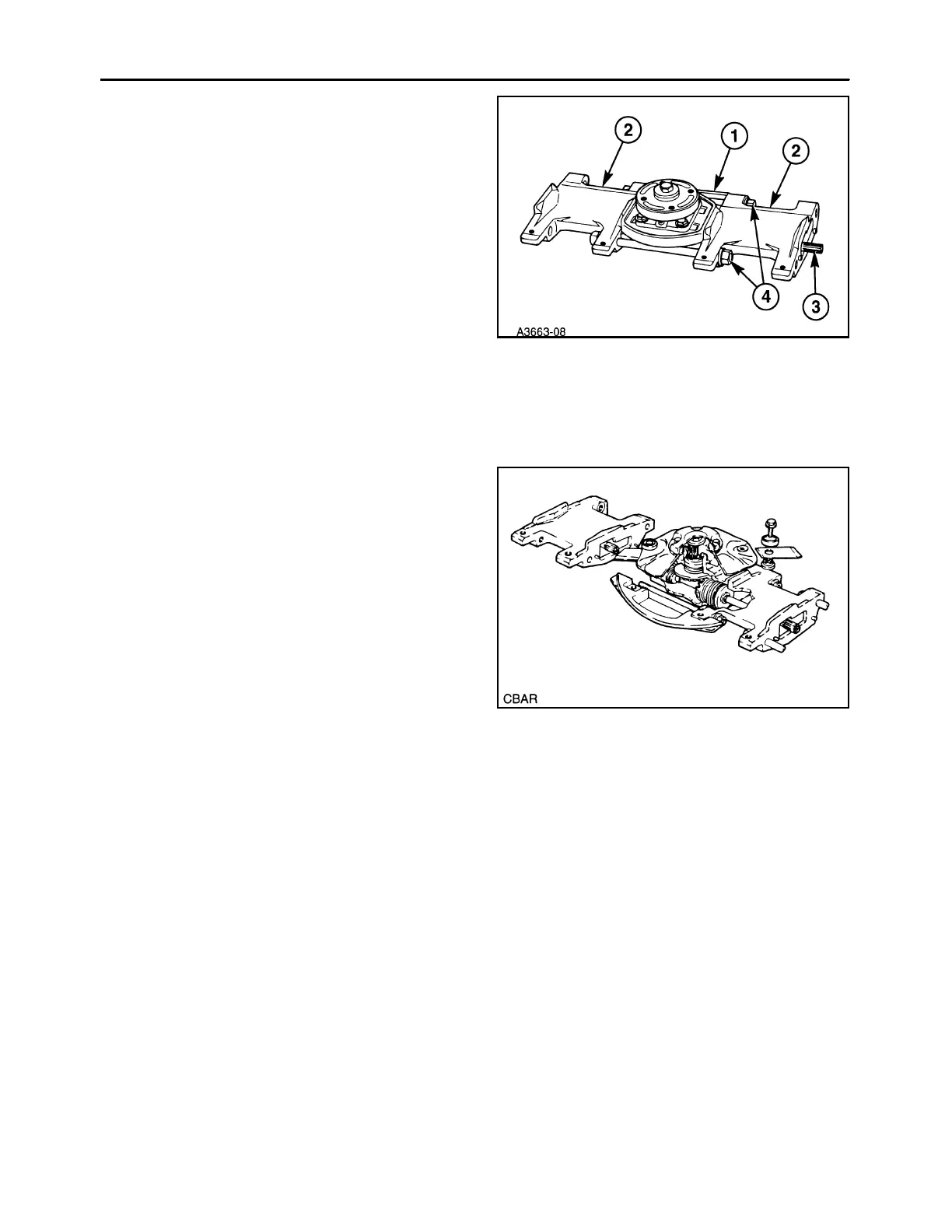

The disc cutterbar is designed and produced, and is

based on a true modular design. Gearbox modules,

1, are connected by independent, hardened alloy

steel drive shafts, 3, running through spacer mod-

ules, 2, and the entire cutter bar is assembled using

high strength tie bolts, 4, to clamp the disc modules

between the spacers. In the unlikely event of cata-

strophic failure, damage is contained to one module,

which can be easily replaced without disturbing other

modules.

1

Each disc module is a separate gear case with its

own oil sump, and utilizes precision forged gears for

strength. Each module consists of a top cap assem-

bly and a lower module assembly.

The top cap assembly consists of the top cap hous-

ing, a bevel gear shaft, a matched bearing set and a

disc hub. The top cap assembly can be removed

from the module for servicing, without disassembling

the cutter bar.

The lower module assembly consists of the lower

module housing and the pinion shaft and bearing as-

sembly. Because the pinion shaft runs at 5400 RPM,

steel slingers are mounted at each end to splash oil

on the shaft seals for lubrication and cooling.

The direction of rotation of the disc module is deter-

mined by the installation of the pinion shaft. If the pin-

ion shaft is installed with the gear positioned on the

right side of the housing, the disc will rotate clock-

wise. Installing the pinion shaft with the gear to the

left will rotate the disc counterclockwise.

2

Loading...

Loading...