SECTION 00 -- GENERAL INFORMATION -- CHAPTER 2

00-10

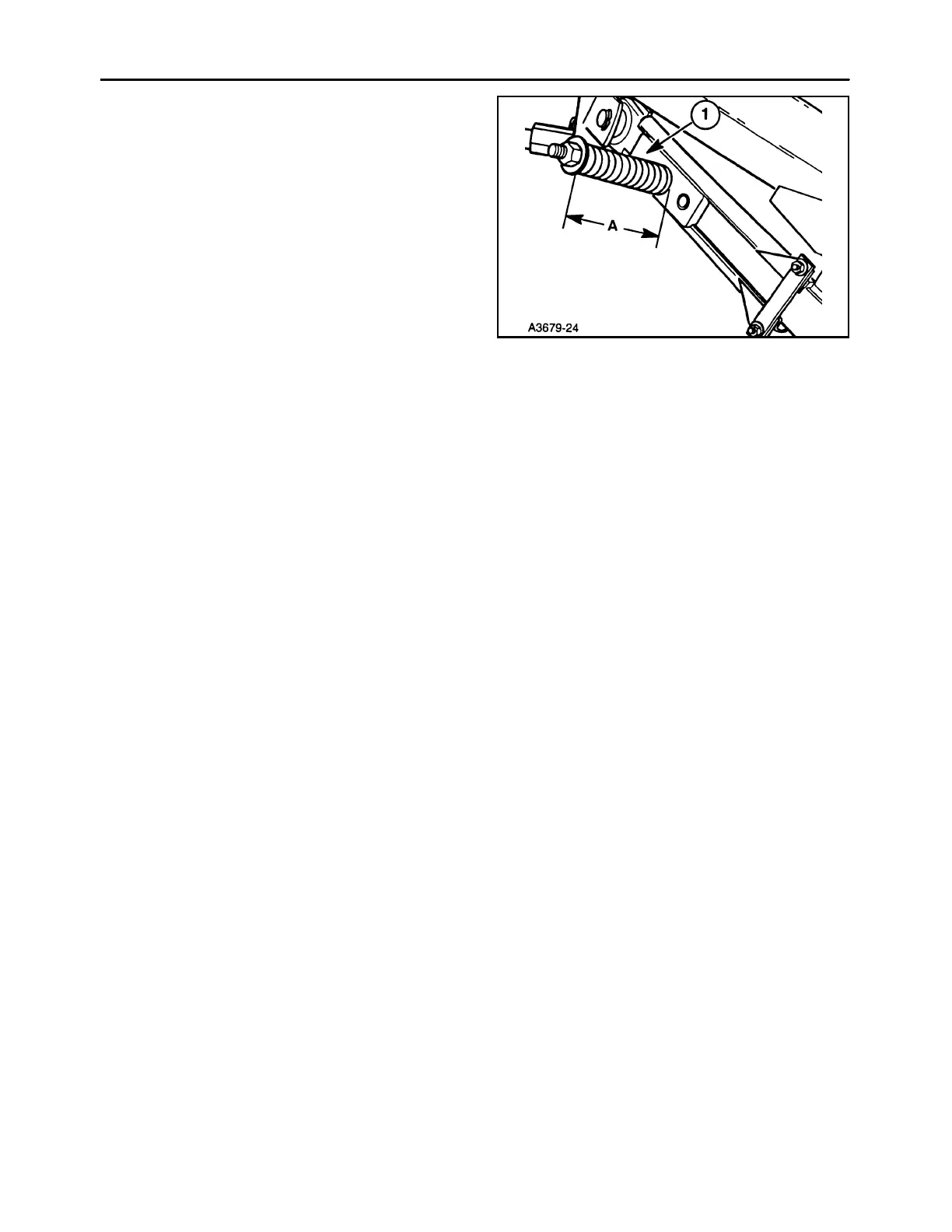

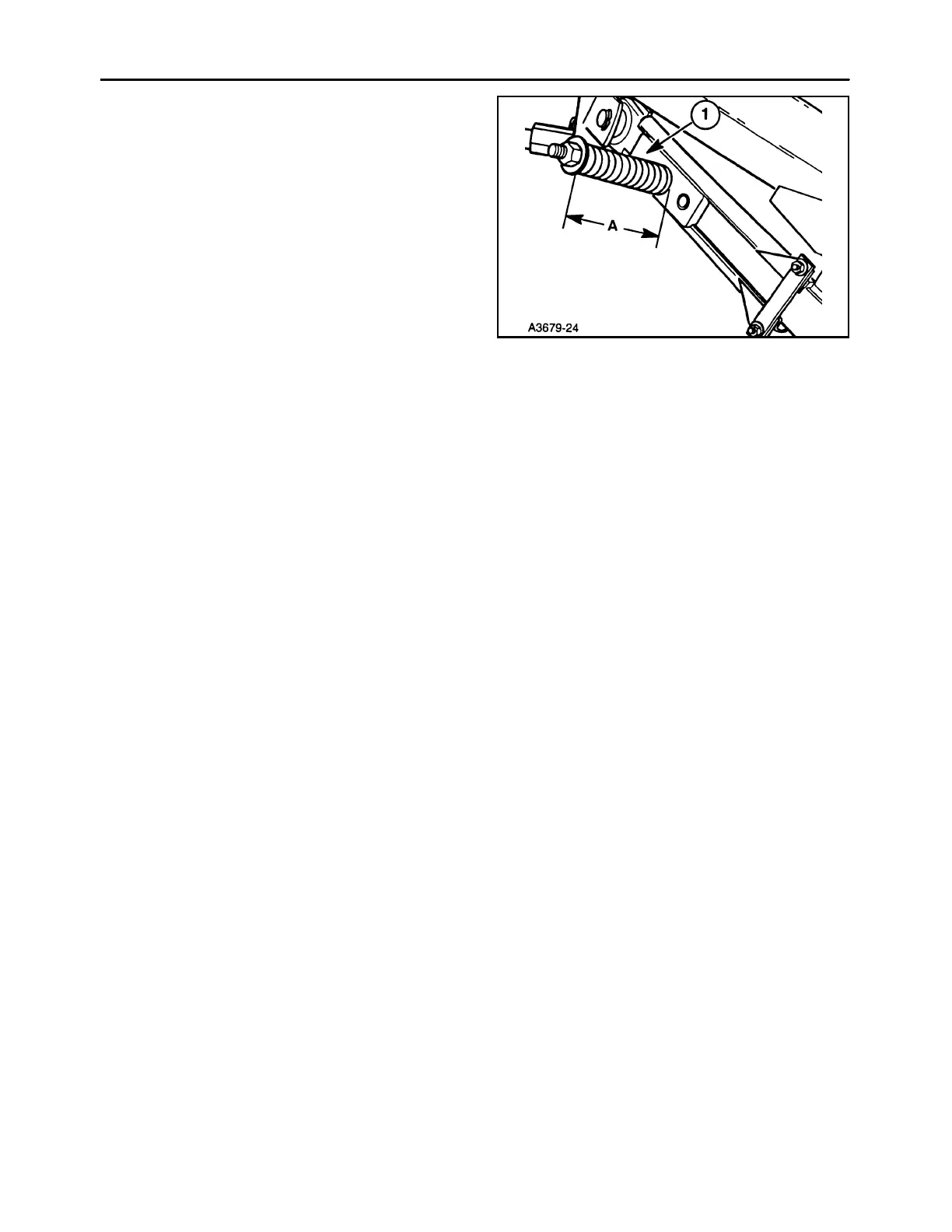

BREAKAWAY LATCH

The mower can be operated at high speeds depend-

ing on crop and field conditions. In rough field condi-

tions, the ground speed should be reduced. The

mower is protected with a breakaway system. If an

obstruction is hit, the breakaway latch, 1, will break

away and the cutter bar will swing rearward.

NOTE: If the latch releases, stop the tractor immedi-

ately and disengage the PTO.

To reset the cutter bar, back the tractor and mower

until the cutter bar latches and is in its normal posi-

tion. Do not raise the cutter bar to re- latch the break-

away.

Check for any cutter bar damage if an obstruction is

encountered.

The breakaway latch consists of a spring loaded

pawl and dog. The spring mount is designed to pro-

vide a range of adjustment for the dif ferent widths of

mowers and different operating conditions; initially,

adjust the spring length, A, as follows:

MDX71 Disc Mower: 6-3/4″

MDX81 Disc Mower: 6-1/2″

MDX91 Disc Mower: 6-1/4″

If the disc mower is operated in rough terrain, and ex-

cessive breakaways are experienced, the spring

may be further tightened as necessary to eliminate

nuisance breakaways.

NOTE: Do not tighten spring to a length less than

5-7/8

″

or structural failure of the mower may occur.

9

If the spring nut is fully tightened, and excessive

breakaways are still experienced, check the follow-

ing areas:

• The disc mower is properly attached to the tractor

as described in the “General Information” section

of the operator’s manual and this repair manual.

If the disc mower is not properly attached, the

performance of the breakaway will be affected.

• Insufficient cutter bar flotation force. With the

flotation properly adjusted, it should be possible

to lift the outer end of the cutter bar with approx.

150 lbs force. In rougher fields, it may be neces-

sary to further lighten the flotation force.

• The tractor hydraulic valve controlling the lift cyl-

inder must be in the float position, to allow the

cutter bar to float independently. If the valve is not

in float, the cutter bar will be affected by tractor

motion in the field.

• Excessive ground speed for field conditions. If

the stubble height is erratic, and the mower is

bouncing excessively, the operator is travelling

too fast for the conditions.

• Excessive wear on the dog may cause repeated

breakaways. If the dog appears to be worn, re-

move it and rotate it to use the opposite ramp sur-

face.

• Dog mounting bolts loose. The dog is retained

with two 1/2″ cap screws. If these cap screws

loosen up, the dog will tip rearward, increasing

the ramp angle. These two cap screws should be

secured with a locking agent and torqued to 83

ft lbs (112.5 N⋅m).

Loading...

Loading...