Chapter 11 – Appendix-A UL Marking

vii

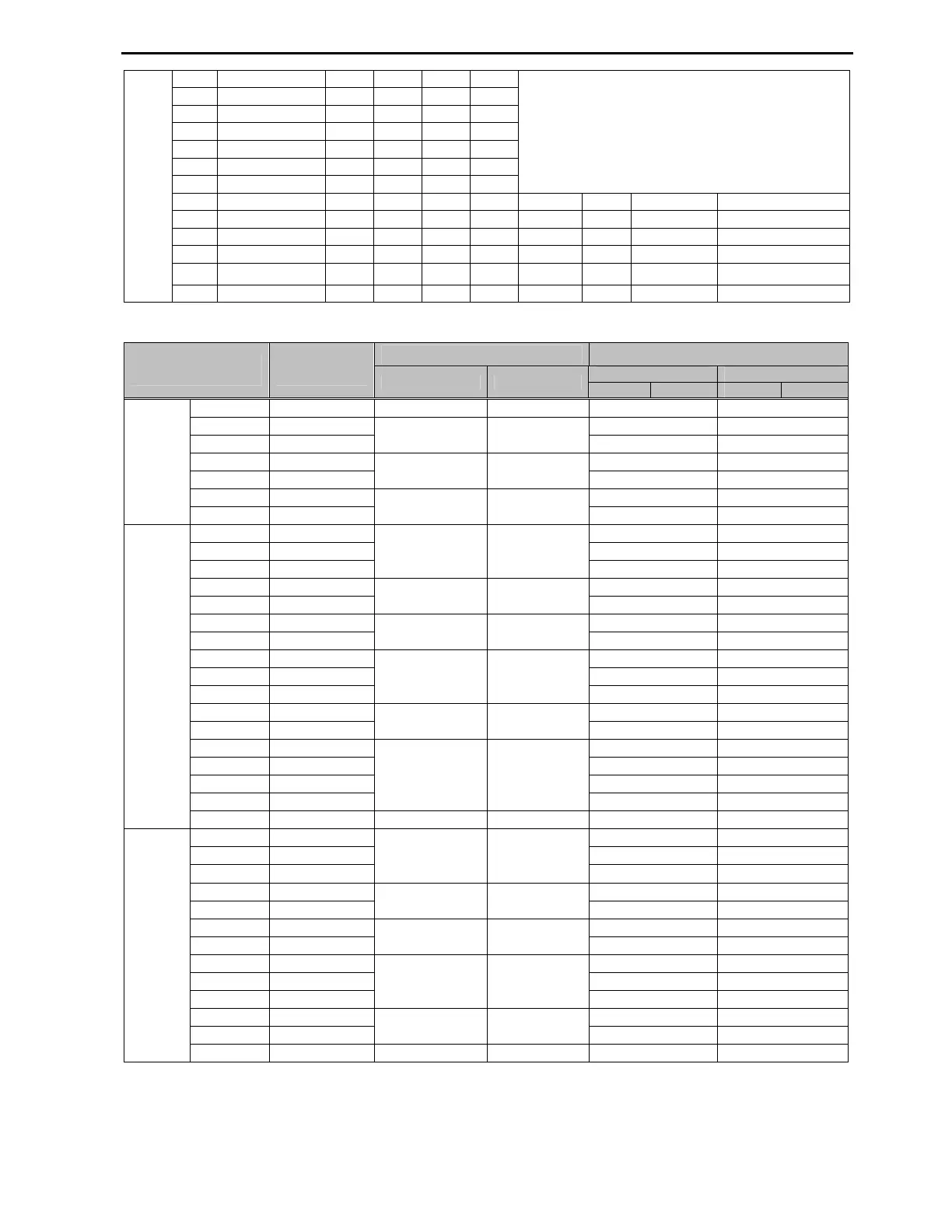

600V

Class

7.5 CI-007-P/4 20 600 30 600

10 CI-010-P/4 30 600 30 600

15 Ci-015-P/4 40 600 50 600

20 CI-020-P/4 60 600 60 600

25 CI-025-P/4 70 600 75 600

30 CI-030-P/4 80 600 100 600

40 CI-040-P/4 100 600 125 600

50 CI-050-P/4 125 600 125 600 160 660 Hinode 660GH-160SUL

60 CI-060-P/4 150 600 150 600 160 660 Hinode 660GH-160SUL

75 CI-075-P/4 175 600 175 600 200 660 Hinode 660GH-200SUL

100 CI-100-P/4 250 600 225 600 250 660 Hinode 660GH-250SUL

125 CI-125-P/4 300 600

300 600

315 660 Hinode 660GH-315SUL

150 CI-150-P/4 350 600

400 600

200×2P 660 Hinode 660GH-200SUL×2P

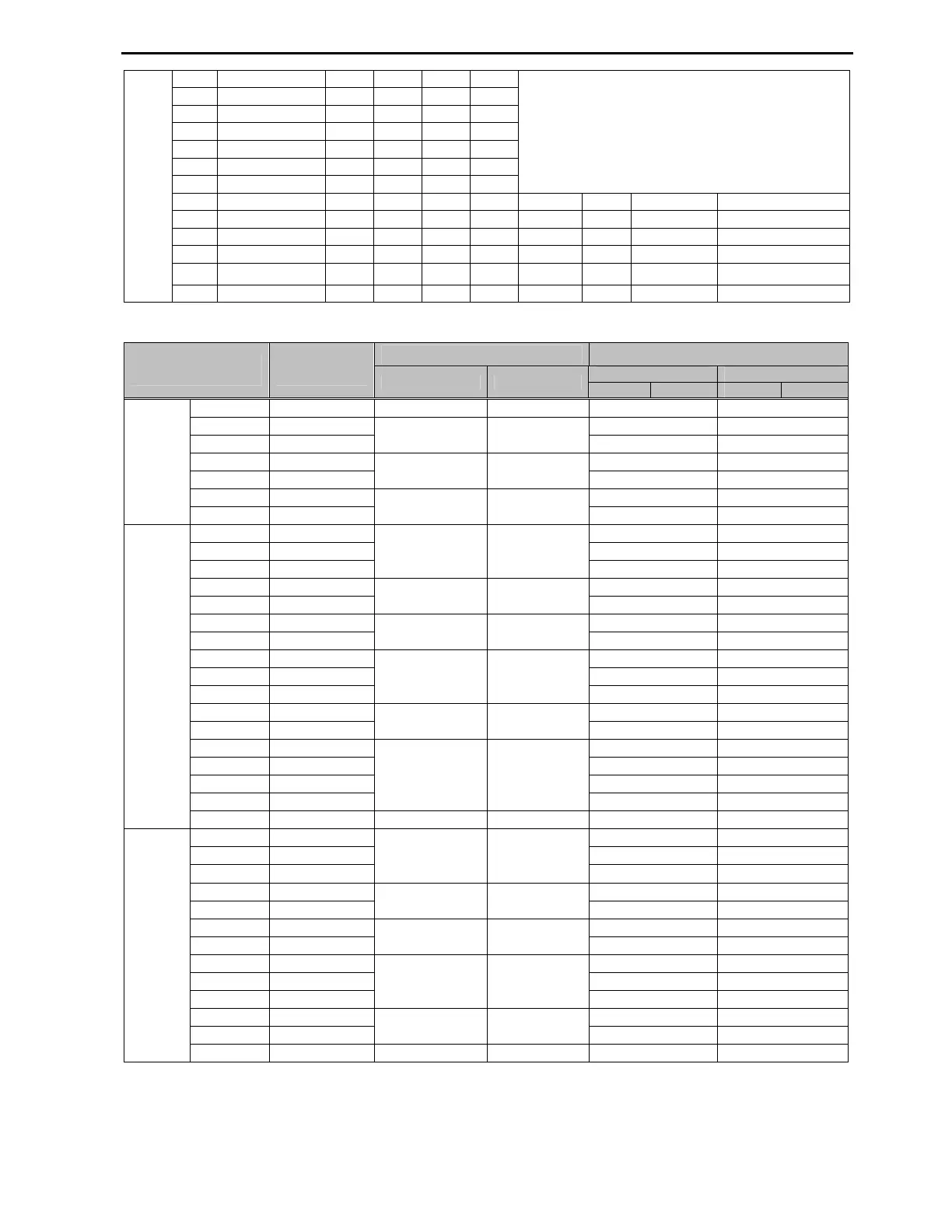

11.3 Terminal Screws, Torque and Wire Gauge

VFD Capacity

[HP]

Terminal

Screw Size

1

Screw Torque

2

Wire

Kgf·cm lb-in

200V

Class

7.5 M4 7.1 ~ 12.2 6.2~10.6 5.5 10

10 M5

24.5 ~ 31.8 21.2~27.6

8 8

15 M5 14 6

20 M6

30.6 ~ 38.2 26.6~33.2

22 4

25 M6 38 2

30 M8

61.2 ~ 91.8 53.1~79.7

38 2

40 M8 60 1/0

400V

Class

7.5 M4

7.1 ~ 12.2 6.2~10.6

3.5 12

10 M4 3.5 12

15 M4 5.5 10

20 M6

30.6~38.2 26.6~33.2

8 8

25 M6 14 6

30 M8

61.2~91.8 53.1~79.7

22 4

40 M8 22 4

50 M8

67.3~87.5 58.4~75.9

38 2

60 M8 38 2

75 M8 38 2

100 M10

89.7~122.0 77.9~105.9

60 1/0

125 M10 60 1/0

150 M12

182.4~215.0 158.3~186.6

100 4/0

200 M12 100 4/0

250 M12 150 300

350 M12 200 400

400 M12 182.4~215.0 158.3~186.6 250 500

600V

Class

7.5 M4

2.0~6.1 1.8~5.2

3.5 12

10 M4 3.5 12

15 M4 5.5 10

20 M6

30.6~38.2 26.6~33.2

8 8

25 M6 14 6

30 M8

61.2~91.8 53.1~79.7

22 4

40 M8 22 4

50 M8

67.3~87.5 58.4~75.9

38 2

60 M8 38 2

75 M8 38 2

100 M10

89.7~122 77.9~105.9

60 1/0

125 M10 60 1/0

150 M12 182.4~215.0 158.3~186.6 100 4/0

Notes:

1

Apply the rated torque to terminal screws. Use copper wires 600V, 75°C rated.

2

Use ring type lugs for power wiring of 7.5~15HP 240V VFDs

Loading...

Loading...