1 Operational Manual

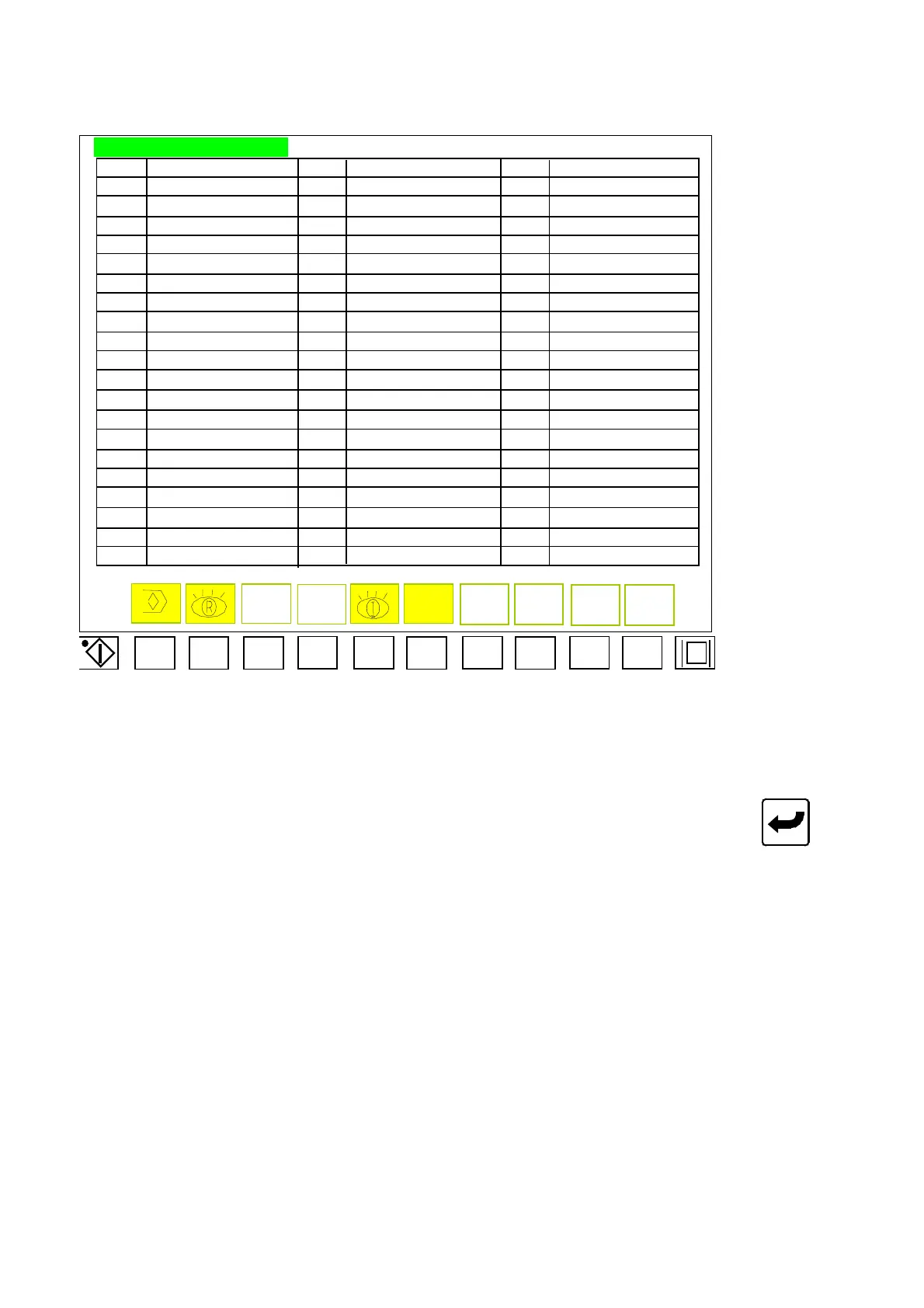

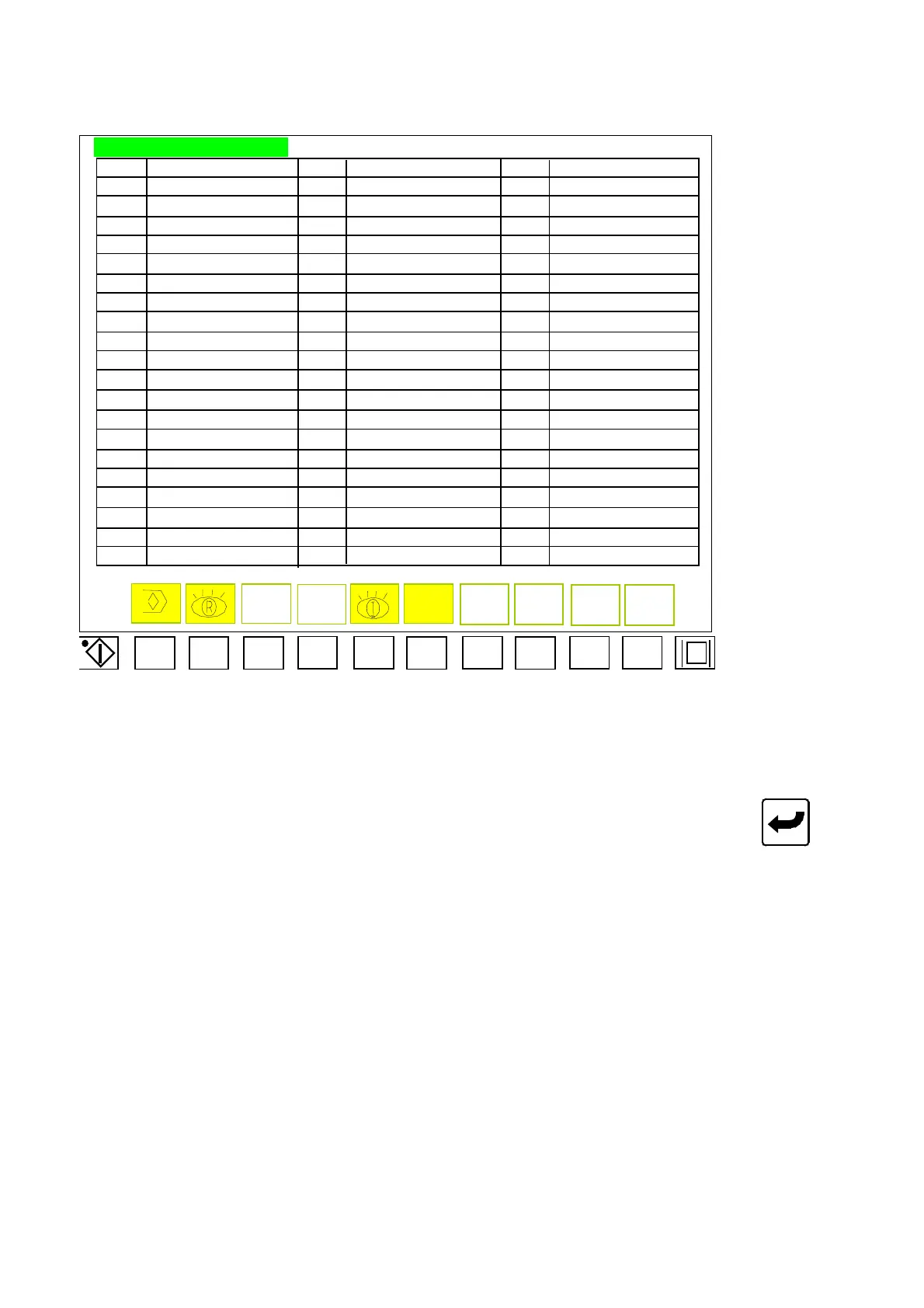

OUTPUT MONITORING PAGE

NO. CONTENT NO. CONTENT NO. CONTENT

PENU. DOOR CLOSE 61 PNEU. DOOR OPEN 62 NOZZLE FORWARD

63 INJECTIN 64 FEEDING 65 DECOMPRESSION

66 NOZZLE BACKWARD MOLD OPEN/CLOSE 68 EJECTOR FORWARD

EJECTOR BACKWARD 70 BOOST CLAMPING 71 CORE 1 IN

72 CORE 1 OUT 73 UNSCREW-IN 74 UNSCREW-OUT

75 THINNER 76 THICKER 77 ACCUM. PRESSED

78 ACCUM. INJECTION 79 PNEU.DOOR SLOW 80 AIRBLOW AT END

81 AIRBLOW AT OPENING 82 FEEDING AT OPENING 83 CORE 2 IN

84 CORE 2 OUT 85 LOCK-UP CLOSE 86 LOCK UP OPEN

87 BOOST 88 SPARE 89 SAPRE

90 SAPRE 91 SYSTEM FUNCTION 92 SPARE

93 SPARE 94 SPARE 95 SPARE

96 SPARE 97 SPARE 98 SPARE

99 SPARE 100 SPARE 101 SPARE

102 SPARE 103 SPARE 104 SPARE

105 SPARE 106 SPARE 107 SPARE

108 SPARE 109 SPARE 110 SPARE

111 SPARE H. MOTOR START-UP H. MOTOR RUNNING

114 ALARM 115 LUBRICATION 116 HEATER BAND

117 SPARE 118 SPARE 119 SPARE

Menu 41

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

60

67

69

112 113

Move cursor to set parameter of opening mold. Key in desired digits and press

to

complete a correction. Code descriptions of menu 33 are as follows:

A) AA: Speed Setup for Accumulator Pressurized

B) BB: Pressure Setup for Accumulator Pressurized

C) CC: Speed Setup for Hydraulic Nozzles

D) DD: Pressure Setup for Hydraulic Nozzles

E) EE: Speed Setup for Special Mold-closing Low-pressure

F) FF: Pressure Setup for Special Mold-closing Low-pressure

G) GG: Speed Setup for Spare 1

H) HH: Pressure Setup for Speed 1

I) II: Speed Setup for Booster Cylinder Mold Adjustment

J) JJ: Pressure Setup for Booster Cylinder Mold Adjustment

K) KK: Pressure Relief Speed Setup for Positioning Cylinder

L) LL: Pressure Relief Pressure Setup for Positioning Cylinder

04/08/13

138

Loading...

Loading...