1 Operational Manual

05/02/03

196

4. Selecting Operational Description

4.1 The Control By Combined Injection Machine and Robotic Arm

4.1.1 Input Node Control of Injection Machine

A) Input 32- Confirmed signal of robot, when robot is used, the signal is “OFF”, otherwise,

the signal is “ON”.

B)

Input 33-Confirmed signal of product was gotten by robot in auto mode, when the

product is obtained, the signal is

“

ON

”

, otherwise, and the signal is

“

OFF

”

.

C)

Input 34-The robot can do ejector advance in auto mode while the signal is

“

ON

”

.

D)

Input 35

- Robot can control the mold’s closing of injection machine while the signal is

“ON”. If “OFF” appear then injection machine can’t close the mold and “064” warning

will appear.

4.1.2 Output Node Control of Injection Machine

A) OUT 85-In auto mode, when injection was finished, the signal is

“

ON

”

.

B) OUT 86-When open mold stops, the signal is

“

ON

”

.

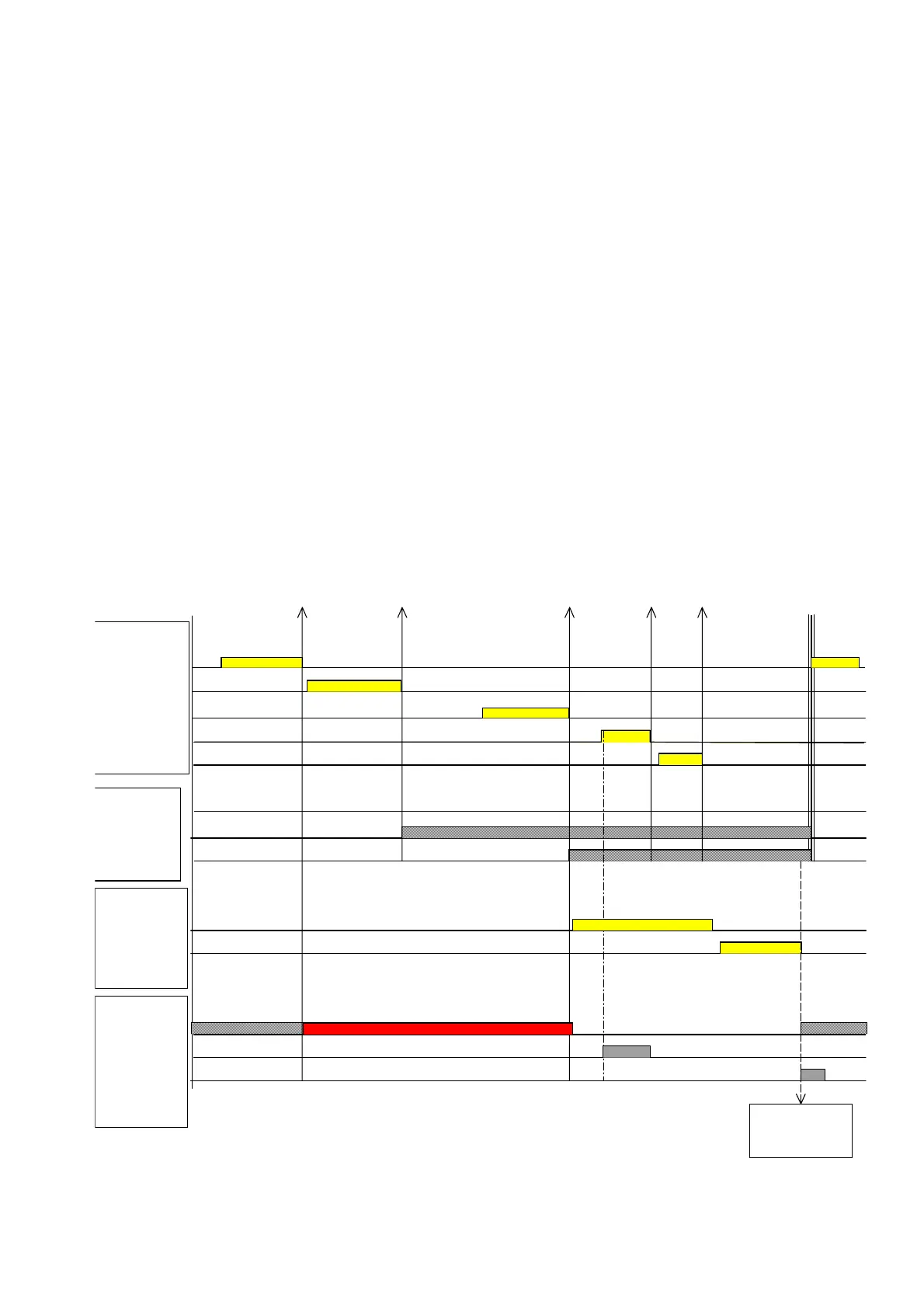

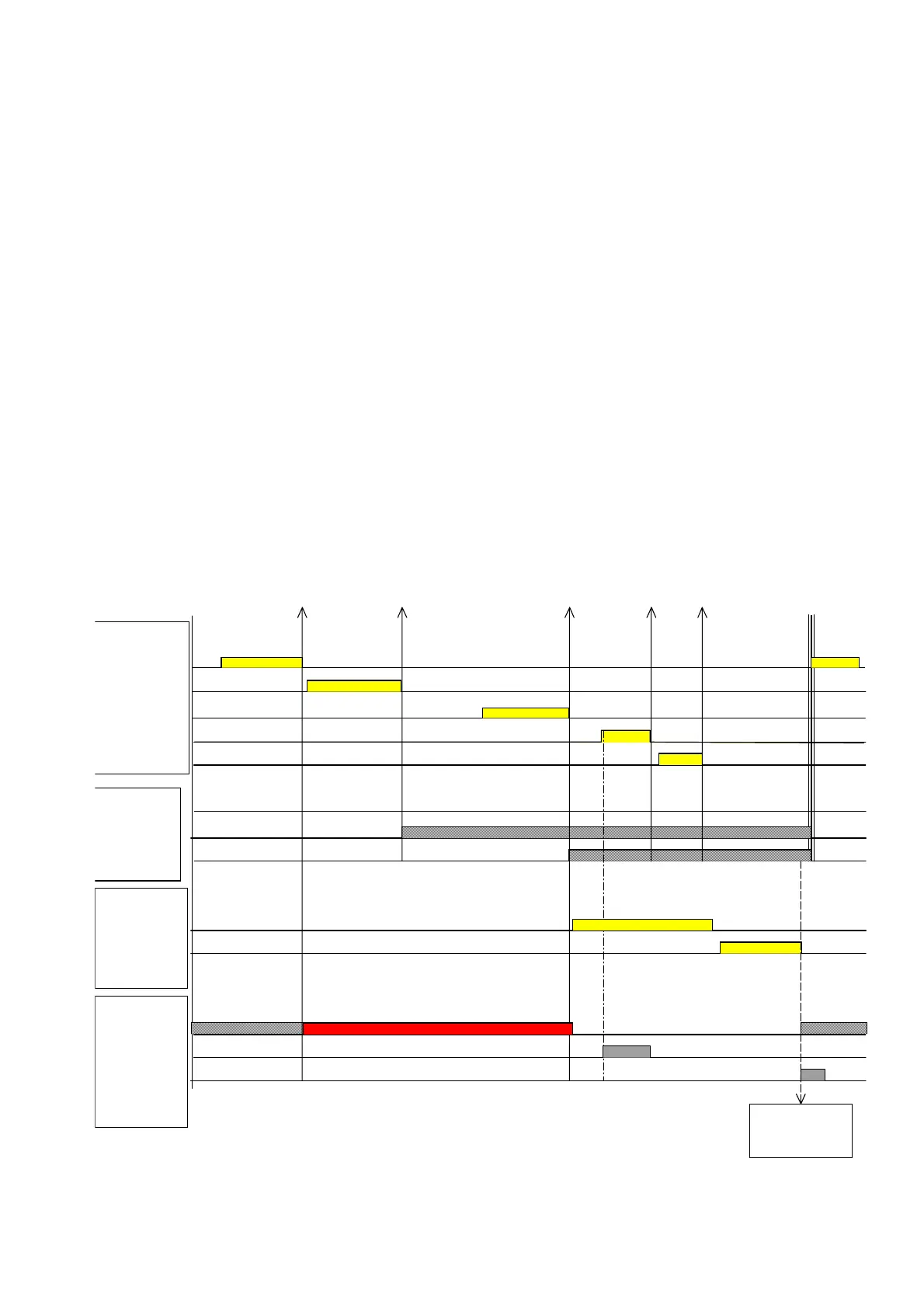

4.1.3 Operational Procedure

tion

-Closing

ion

-Opening

r Forwar

r Backward

End of Mold-Closing Injection finished End of Mold-Opening Ejector Ejector

Forward Backward

Finished Finished

Robot’s

Operation

Up

Down

Output

OUT85

OUT86

Robot’s

Output

Come Back

Ejector Out

Confirmation

Confirmation

of Product

4.1.4 Operational Descriptions:

When the robot was used (Machine signal is Input 32 OFF), whether the injection

Loading...

Loading...