1 Operational Manual

05/02/03

198

select “close-loop” or “close-loop +auto hold-pressure” and press to complete a

correction.

(B) Operational Method:

The function is feedback of oil pressure and showing the pressure in the menu.

In auto mode, the filling procedure, the amount of material depends on the need and injects

into mold cavity. Compare forward speed and setting value, correct injecting speed

automatically. In pressure holding sensor tells the actual liquid pressure and pressure

holding setting.

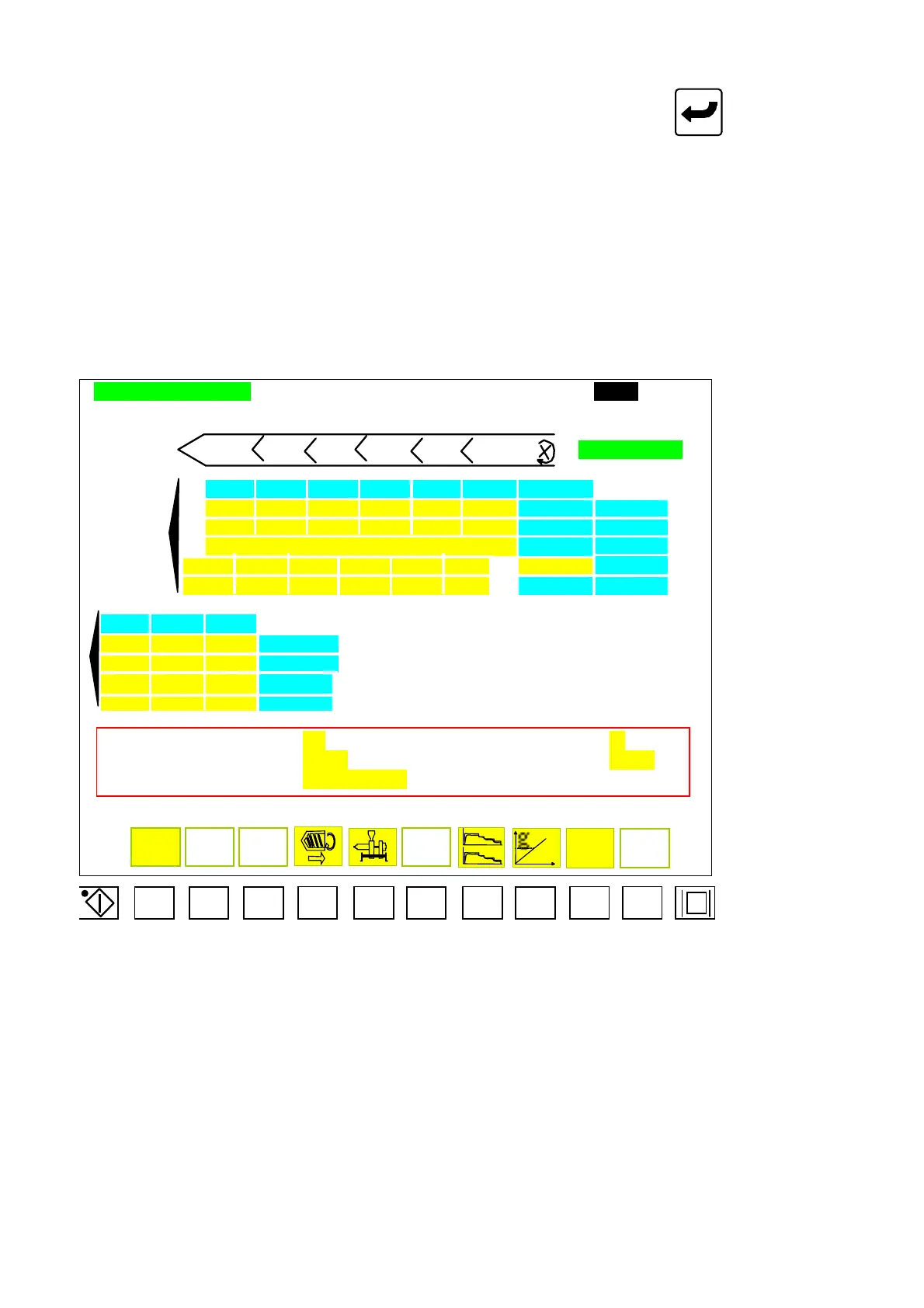

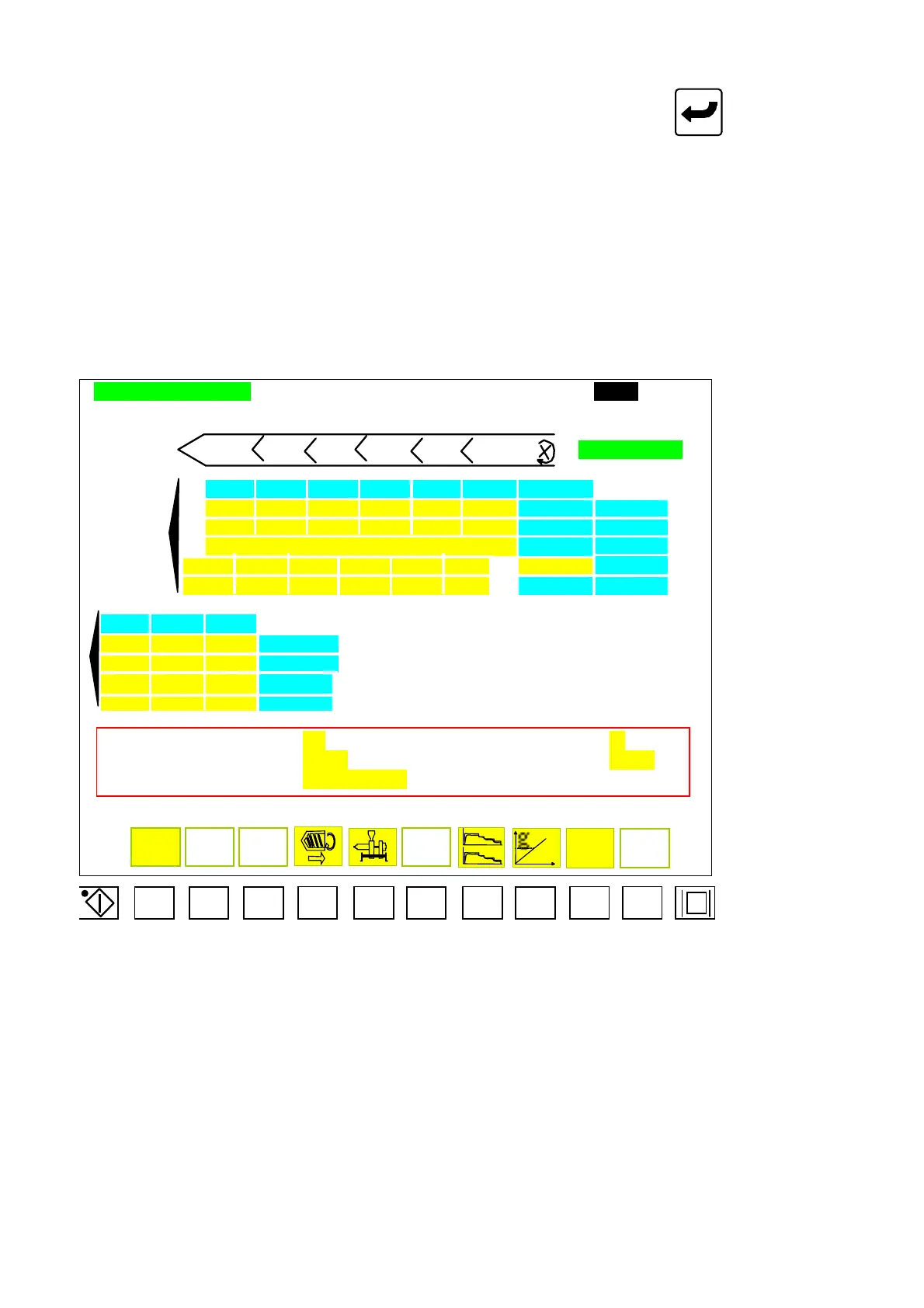

INJECTION SETTING ????.?mm

CUSHION END : uuuu.umm FILLING TIME : xx.xxSEC FEEDING TIME : wwww.wSEC

Tt.ff Tt.ee Tt.dd Tt.cc Tt.bb Tt.aa

TIME OD STAGE

6 5 4 3 2 1 DOSING END

UU QQ MM II EE AA SPEED %

VV RR NN JJ FF BB PRESSURE%

zzz.z TIME SEC

WWW.W SSS.S OOO.O KKK.K GGG.G CCC.C ZZZ.Z POSITION

XX TT PP LL HH DD 100% PERSENT%

3 2 1

gg dd aa SPEED %

hh ee bb PRSSSURE %

iii.i fff.f ccc.c TIME SEC

pp.p oo.o nn.n SLOPE %

HOLDING PRESSURE AT :

jjjbar BOOST INJECTION: k

INJECT LEAKAGE POSTION:

llll.lmm INJECTION CHOCKED POSTION: mmmm.mmm

INJECTION MODE:

nnnnnnnnnnnnnn

SET

Menu11

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

4.3 Optic Meter’s Vibrating Ejector Function

4.3.1 Setting Method:

(A)

In ejector menu 05 to set

“

ejector NO. :NNNNN

”

and

“

vibrating

NO.

”

PPPPP

“

parameter.

(B)

Set ejector forward, backward speed, pressure and position.

(C)

Select ejector

‘

s function

“

MMMMMMMMM to

“

vibrate ejector

”

.

Loading...

Loading...