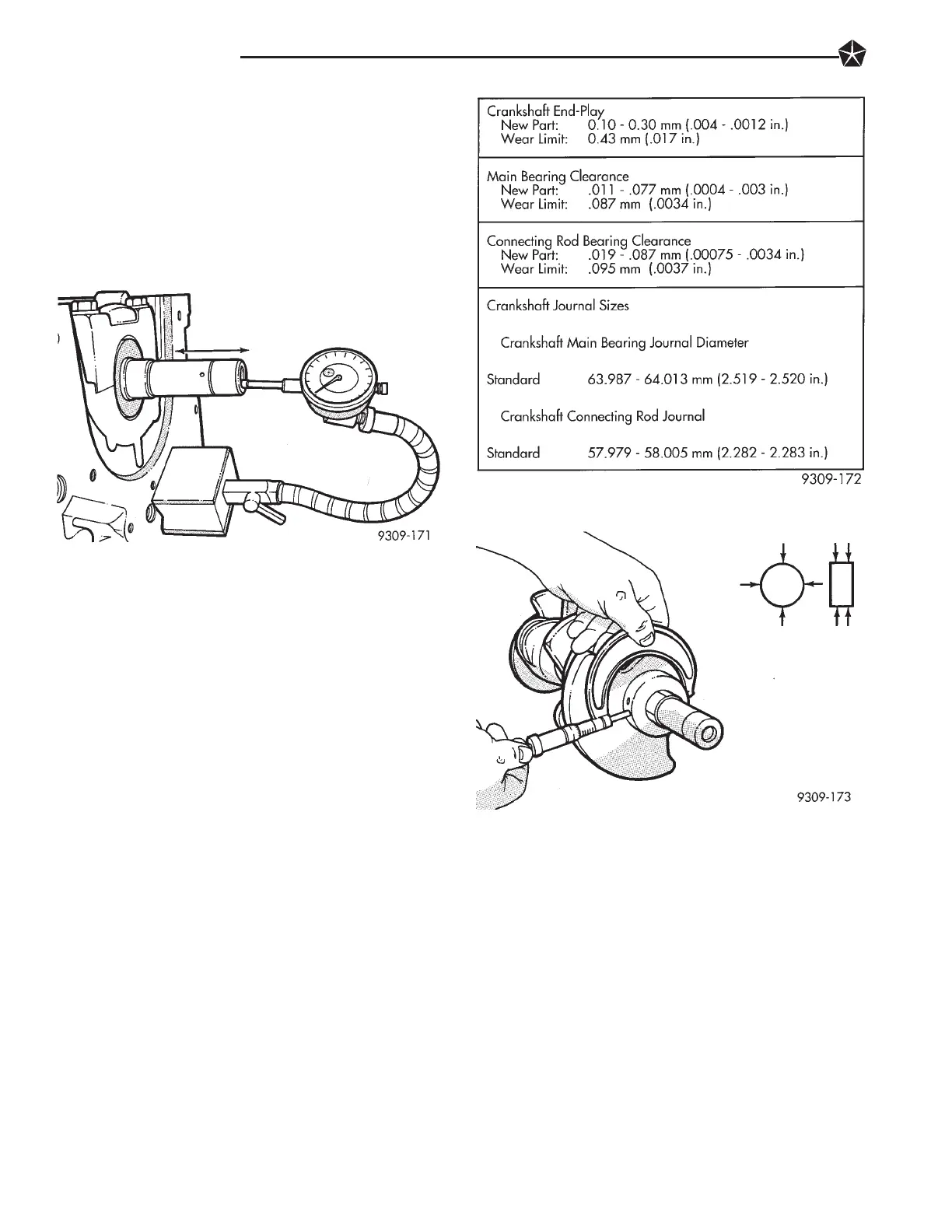

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 5).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to (Fig. 6) for specifica-

tion.

CRANKSHAFT END PLAY CHECK—OPTIONAL

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

cap and a crankshaft cheek using care not to damage

any bearing surface.Do notloosen main bearing cap.

(2) Use a feeler gauge between number 2 thrust

bearing and machined crankshaft surface to deter-

mine end play. Refer to (Fig. 6) for specification.

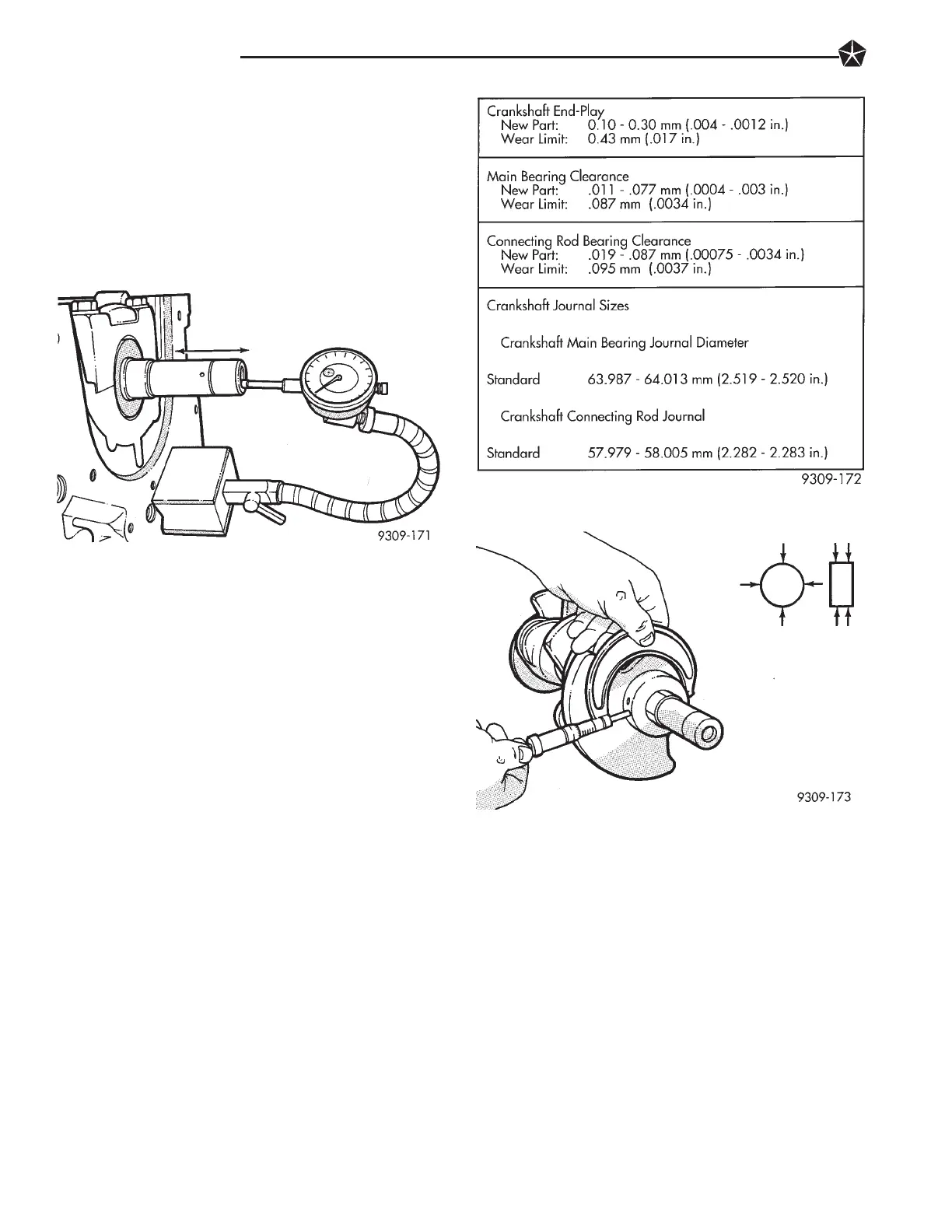

CRANKSHAFT OIL CLEARANCE

(1) Measure the journal outside diameter as shown

in (Fig. 7). Refer to specification (Fig. 6).

PLASTIGAGE (OIL CLEARANCE)

MEASUREMENT

(1) Remove oil from journal and bearing shell.

(2) Install crankshaft.

(3) Cut plastigage to same length as width of the

bearing and place it in parallel with the journal axis

(Fig. 8).

(4) Install the main bearing cap carefully and

tighten the bolts to specified torque.

CAUTION: Do not rotate crankshaft or the plasti-

gage will be smeared.

(5) Carefully remove the bearing cap and measure

the width of the plastigage at the widest part using

the scale on the plastigage package (Fig. 8). Refer to

specification (Fig. 6) for proper clearances. If the

clearance exceeds the specified limits. Replace the

main bearing(s) and if necessary have the crankshaft

machined to next undersize. Also see Measuring

Main and Connecting Rod Bearing Clearance in

Standard Service Procedures.

CAUTION: Do not rotate crankshaft or the Plasti-

gage may be smeared.

CRANKSHAFT OIL SEALS SERVICE

REMOVAL

Pry out rear seal with screwdriver. Be careful not

to nick or damage crankshaft flange seal surface or

retainer bore (Fig. 9).

Fig. 5 Checking Crankshaft End Play

Fig. 6 Crankshaft specification

Fig. 7 Measure Crankshaft Journal O.D.

9 - 60 3.5L ENGINE

Loading...

Loading...