fuel mixture), the sensors produce voltages as low as

0.1 volt. When there is a lesser amount of oxygen

present (rich air-fuel mixture) the sensor produces a

voltage as high as 1.0 volt. By monitoring the oxygen

content and converting it to electrical voltage, the

sensor acts as a rich-lean switch.

The oxygen sensors are equipped with a heating

element. The heating element keeps the sensor at

proper operating temperature during all operating

modes. Maintaining correct sensor temperature at all

times allows the system to enter into closed loop

operation sooner. Also, it allows the system to remain

in closed loop operation during periods of extended

idle.

In Closed Loop operation the PCM monitors the inputs

from the heated oxygen sensors (along with

other inputs) and adjusts the injector pulse width

accordingly. During Open Loop operation the PCM

ignores the inputs fromthe heated oxygen sensors. The

PCM adjusts injector pulse width based on prepro-

grammed (fixed) values and inputs from other sensors.

REMOVAL—3.3L ENGINE

The 3.3Lengine uses two heated oxygen sensors, one

in each exhaust manifold. The sensors point toward the

engine block. For access to the right side sensor,

remove the air cleaner resonator and hose.

(1) Disconnect electrical connector.

(2) Use a crow-foot wrench or open end wrench to

remove heated oxygen sensor (Fig. 7).

After removing the sensor, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If reusing the original sensor, coat the sensor threads

with an anti-seize compound such as Loctitet 771-64 or

equivalent. New sensors have compound on the

threads and do not require an additional coating.

Tighten the sensor to 28 NIm (20 ft. lbs.) torque.

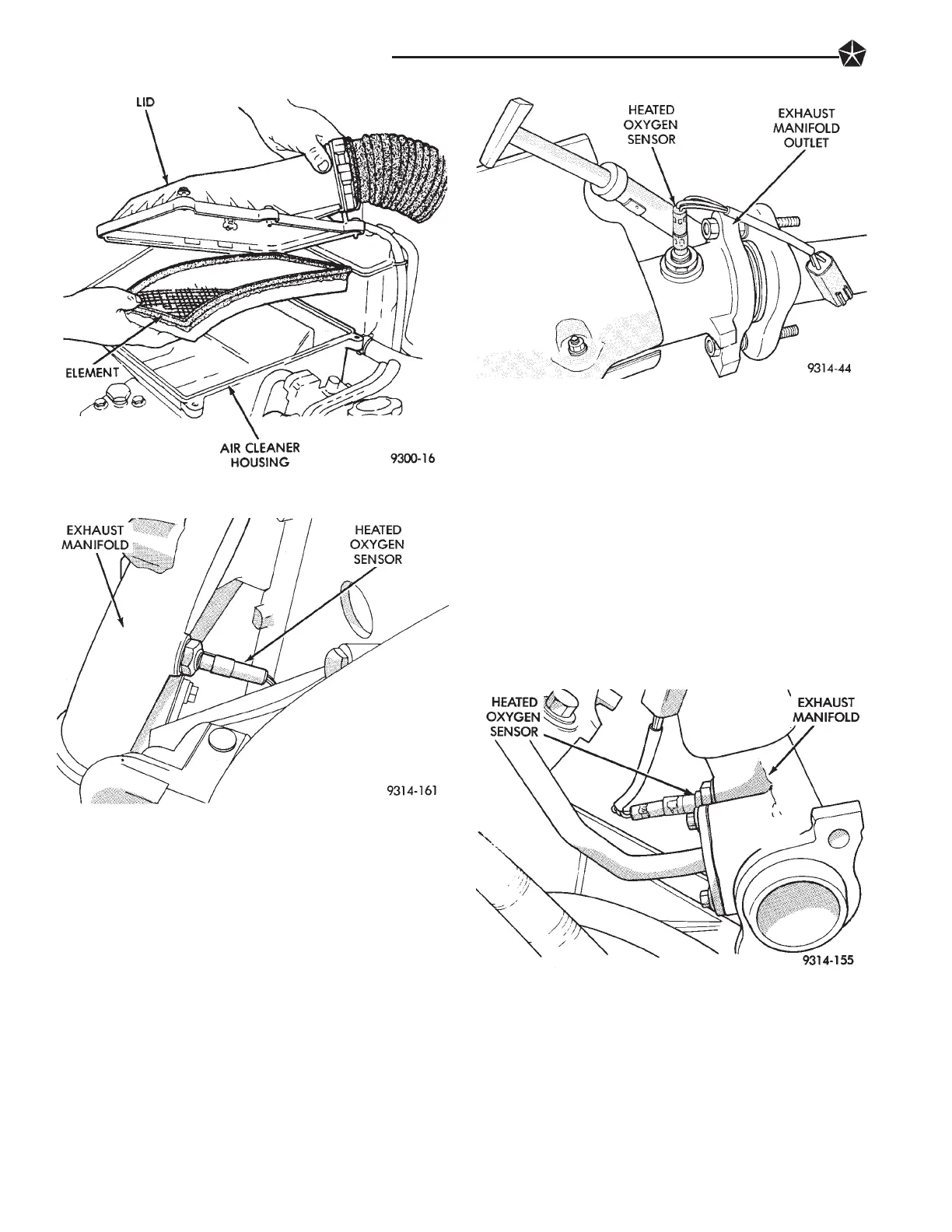

Fig. 4 Air Cleaner Housing and Element

Fig. 5 Heated Oxygen Sensor—3.3L Engine

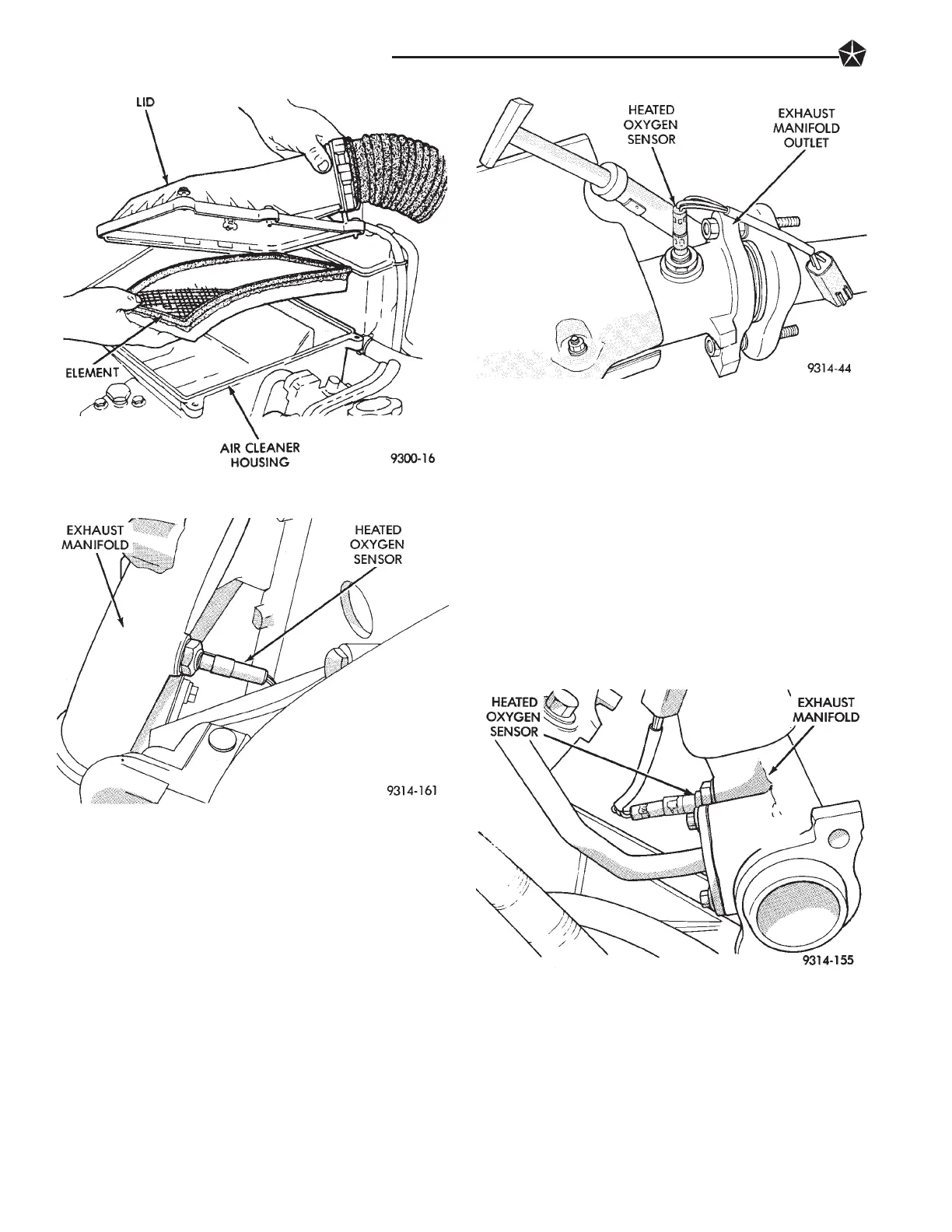

Fig. 6 Heated Oxygen Sensor—3.5L Engine

Fig. 7 Heated Oxygen Sensor

Removal/Installation—3.3L Engine

25 - 10 EMISSION CONTROL SYSTEMS

Loading...

Loading...