CAUTION: When reassembling use a new roll pin

BEARING ADJUSTMENT PROCEDURES

GENERAL RULES ON SERVICING BEARINGS

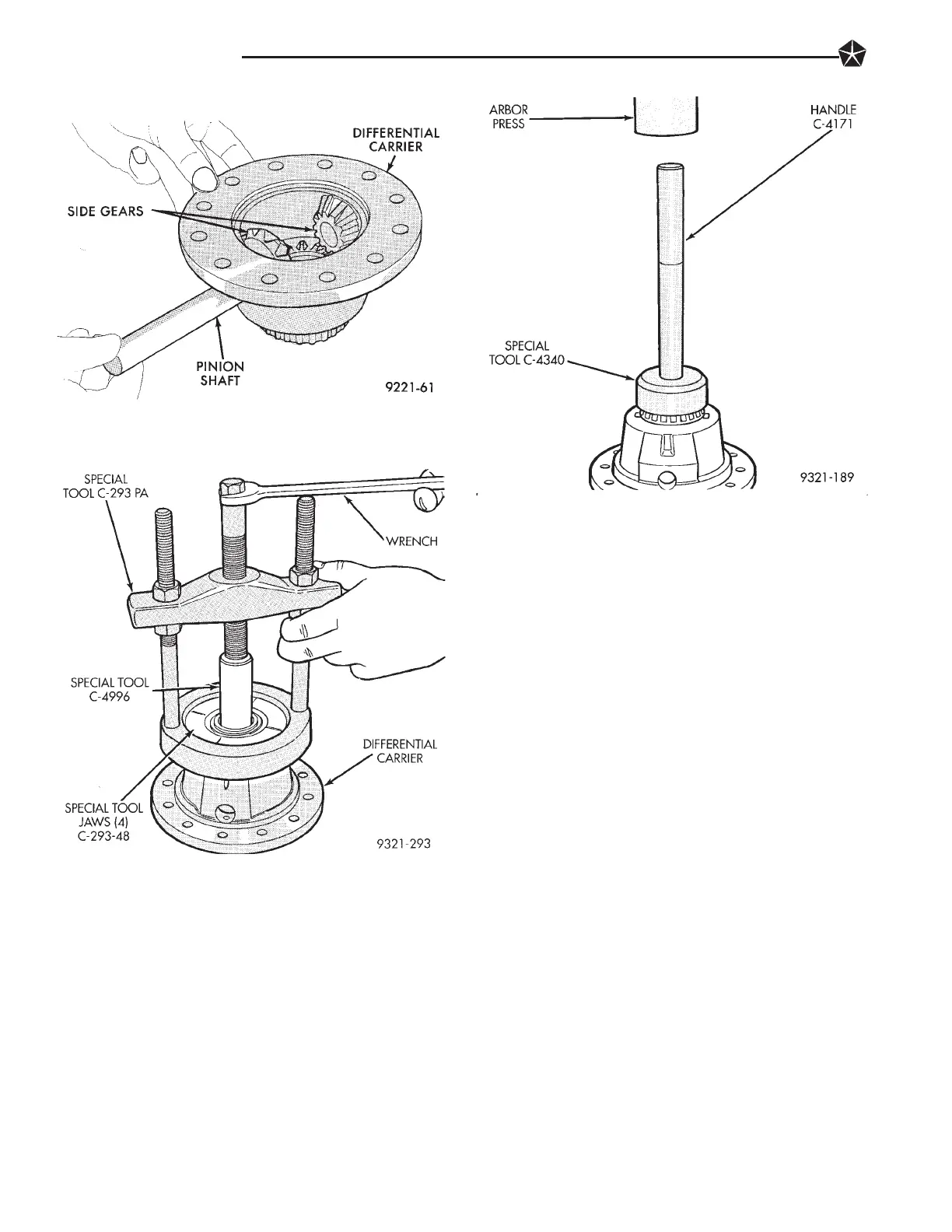

Take extreme care when removing and in stalling

bearing cups and cones. Use only an arbor press for

installation, as a hammer may not properly align the

bearing cup or cone. Burrs or nicks on the bearing seat

will give a false end play reading, while gauging for

proper shims. Improperly seated bearing cup and cones

are subject to low-mileage failure.

Bearing cups and cones should be replaced if they

show signs of pitting or heat distress.

If distress is seen on either the cup or bearing rollers,

both cup and cone must be replaced.

Bearing end play and drag torque specifica-

tions must be maintained to avoid premature

bearing failures.

Used (original) bearing may lose up to 50 percent of

the original drag torque after break-in.

All bearing adjustments must be made with no

other component interference or gear inter-

mesh, except the transfer gear bearing.

Oil all bearings before checking turning torque.

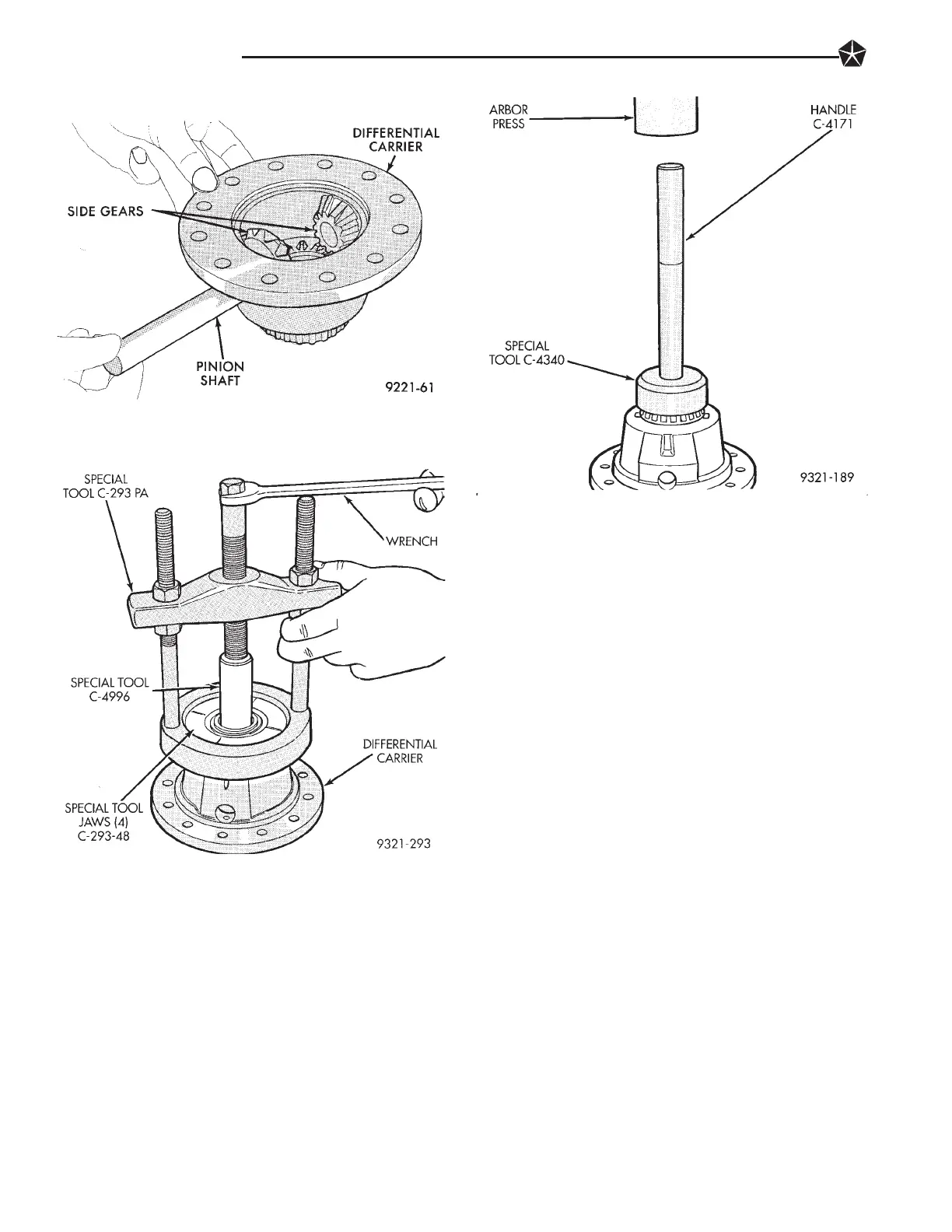

Fig. 6 Slide Out Differential Pinion Shaft and

Remove Pinion Gears and Side Gears

Fig. 7 Carrier Bearing Removal

Fig. 8 Carrier Bearing Installation

21 - 80 TRANSAXLE

Loading...

Loading...