(3) Allow vehicle front wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 30 mph.

(4) The 2/4 clutch pressure should read 75 to 95 psi.

TEST FIVE-SELECTOR IN ‘‘OD’’

These tests checks the torque converter clutch

hydraulic circuit.

(1) Attach gauge to the torque converter clutch off

pressure tap.

(2) Move selector lever to the OD position.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 50 mph.

CAUTION: Both wheels must turn at the same speed.

(4) Torque converter clutch off pressure should be

less than 5 psi.

(5) Now attach the gauge to the torque converter

clutch on pressure tap.

(6) Move selector to the OD position.

(7) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 50 mph.

(8) Verify the torque converter clutch is applied

mode using the RPM display of the DRB II scan tool.

(9) torque converter clutch on pressure should be

60-90 psi.

TEST SIX-SELECTOR IN ‘‘R’’

This test checks the reverse clutch hydraulic

circuit.

(1) Attach gauge to the reverse clutch tap.

(2) Move selector lever to the ‘‘R’’ position.

(3) Read reverse clutch pressure with output sta-

tionary (foot on brake) and throttle opened to achieve

1500 rpm.

(4) Reverse clutch pressure should read 165 to 235

psi.

TEST RESULT INDICATIONS

(1) If proper line pressure is found in any one test,

the pump and pressure regulator are working properly.

(2) Low pressure in all positions indicates a defec-

tive pump, a clogged filter, or a stuck pressure regula-

tor valve.

(3) Clutch circuit leaks are indicated if pressures do

not fall within the specified pressure range.

(4) If the overdrive clutch pressure is greater than 5

psi in step (6) of Test Three, a worn reaction shaft seal

ring is indicated.

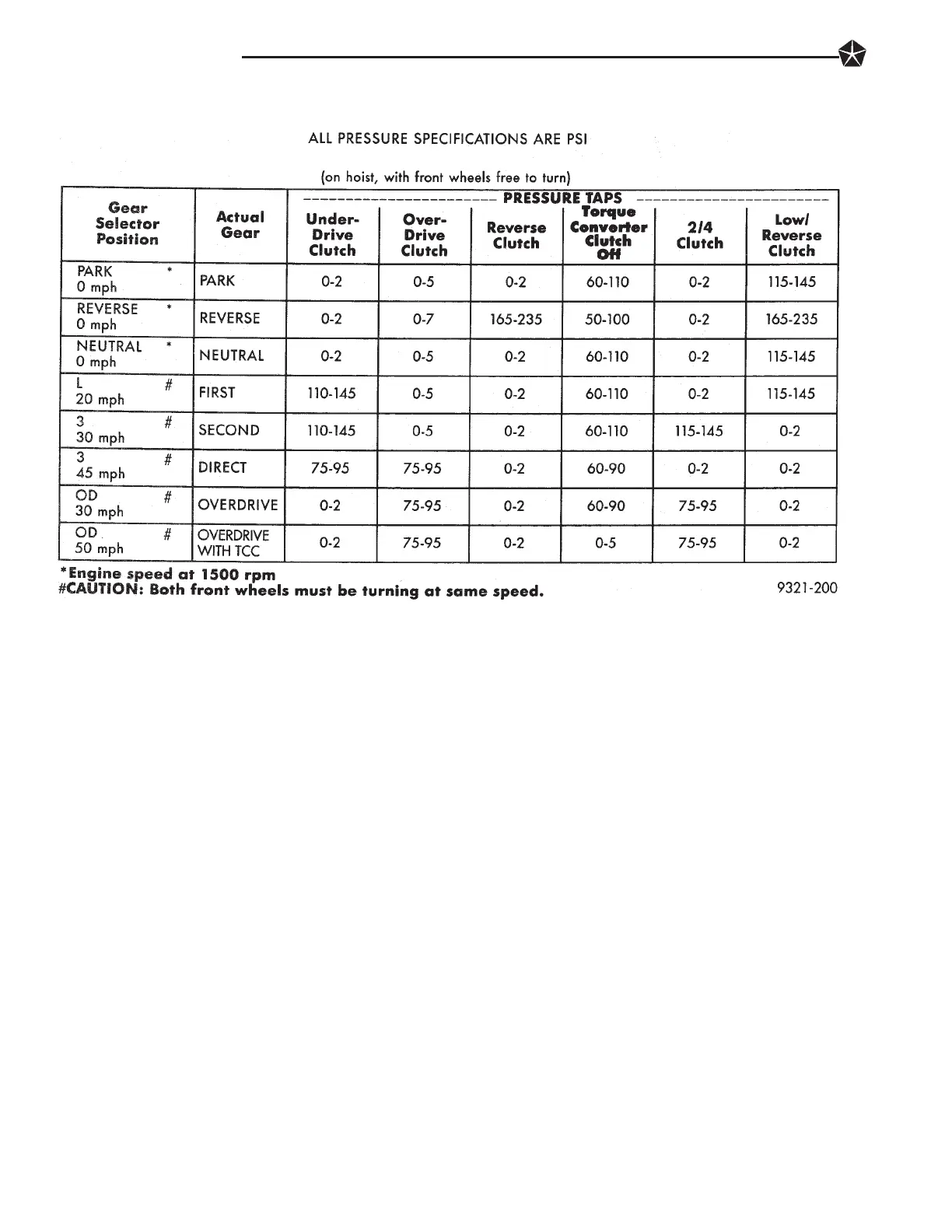

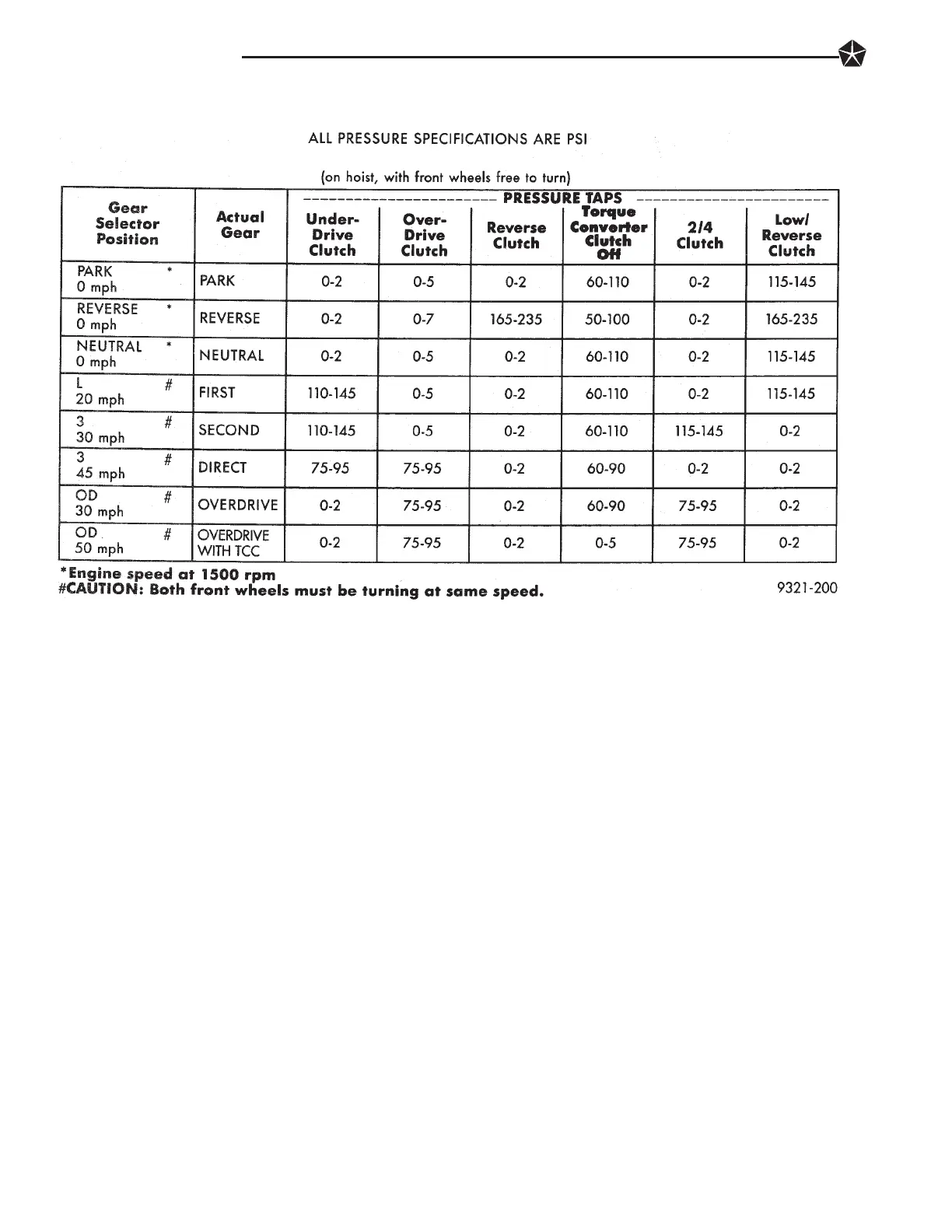

42LE PRESSURE CHECK SPECIFICATIONS

21 - 14 TRANSAXLE

Loading...

Loading...