Page 58 WS2H and WS3 Manual

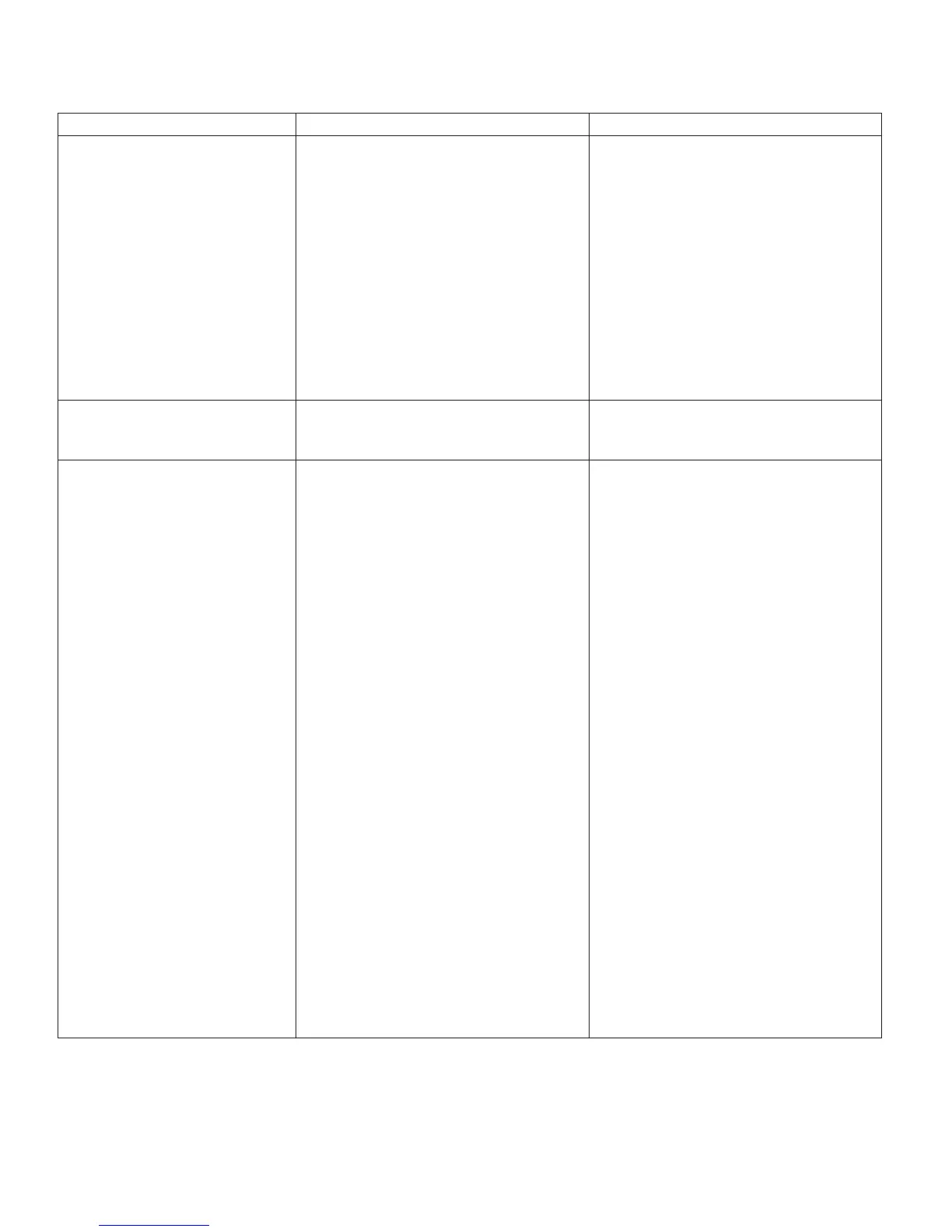

Problem Possible Cause Solution

17. Err – 1003 = Control valve

motor ran too long and was

unable to nd the next cycle

position

a. Motor failure during a regeneration

b. Foreign matter built up on piston and

stack assemblies creating friction and

drag enough to time out motor

c. Drive bracket not snapped in properly

and out of position enough that

reduction gears and drive gear do not

interface

d. Low voltage slowing drive

a. Check motor connections then Press

NEXT and REGEN buttons for about

3 seconds to resynchronize software

with piston position.

b. Replace piston and stack assemblies.

Press NEXT and REGEN buttons for

about 3 seconds to resynchronize

software with piston position.

c. Snap drive bracket in properly then

press NEXT and REGEN buttons for

about 3 seconds to resynchronize

software with piston position.

d. See Table 2 Software and Power

Supply Compatibility

18. Err - 14001 = Message

queue full

a. Master PC Board did not receive a

response from slave units.

a. Press NEXT and REGEN buttons for

about 3 seconds to resynchronize

software with piston position.

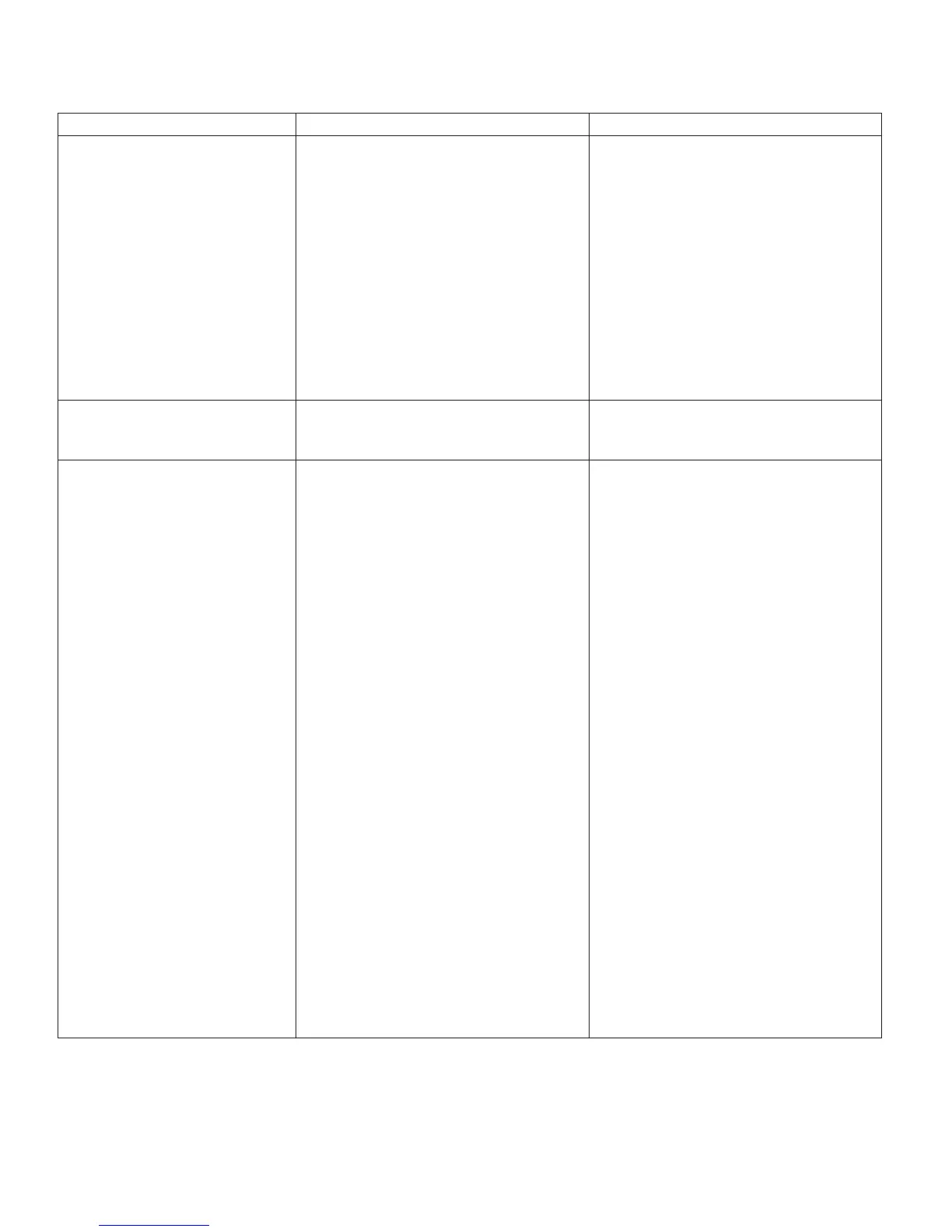

19. Err -15003 = Motorized

Bypass or MAV for NHBP

valve motor ran too long

and unable to nd the

proper park position

Motorized Alternating Valve

= MAV

No Hard Water Bypass

= NHBP

a. Control valve programmed for

ALT A or noHbP without having

a motorized drive securely

connected to the 2 pin terminal

labeled “BYPASS” on the main

PC Board

b. Poor wire connection

c. Excess drag causing timeout

before stall

d. Motorized Bypass or MAV for

NHBP motor not fully engaged

with reduction gears

a. Press NEXT and REGEN

buttons for about 3 seconds

to resynchronize software with

piston position. Then re-program

valve to proper setting

b. Remove power and check

connection for Motorized Bypass

or MAV for NHBP motor to PC

Board two pin connection labeled

BYPASS. Make sure wires in

connector are inserted securely

and no wires are broken. Clean

pins on PC Board by plugging

and unplugging the connector

a few times to remove excess

protective coating. Press NEXT

and REGEN buttons for about

3 seconds to resynchronize

software with piston position.

c. Open up Motorized Bypass or

MAV for NHBP to check for

obstructions

d. Properly insert motor into casing,

do not force into casing. Press

NEXT and REGEN buttons for

about 3 seconds to resynchronize

software with piston position.

WS2H/ WS3 TROUBLE SHOOTING GUIDE (CONTINUED)

Loading...

Loading...