Configuration 5

October 2013 GB 29 /80

External Speed Limit (RS)

This function can be used to temporarily limit the

lower and upper speed of the drive motor, e.g. if

it necessary to limit the maximum delivered air

quantity/power consumption.

Configuring the function "External Speed

Limit" (RPM Limit)

1

Set the desired min/max values in the "Settings

/ Configuration" menu.

2 Allocate an input to this function. See chapter

"Input programming".

As soon as the input is connected, the drive motor

speed only moves within the desired band.

Override Timer Start

If the compressor has been switched off because

of settings in the menu "Timer Start/Stop" (see

chapter "Timer control operation"), this function

will override the timer and start the compressor as

long as the input is activated.

For example, this allows the compressor to be

started by maintenance personnel during a week-

end when the timer would normally have shut

down the compressor.

Pressure Band p2

This function switches the pressure band to pres-

sure band p2.

If this function is active, the menu "Home" (field

"Current Pressure Band") indicates that the pres-

sure band p2 is being used and has been acti-

vated by a programmable input. The programma-

ble input number is also displayed.

Enable Sensor B1

Ex works, the signal for switching the compressor

between on-load and off-load is generated by the

compressed air line pressure sensor B1.

An open input will unload the compressor.

If the input is connected, the sensor controls com-

pressor switching between on-load and off-load.

Enable Remote Load (FS)

If the input is connected, on-load/off-load control

takes place solely via the "Remote Load" function

described below.

Remote Load (FS)

The Remote Load and Off-Load function makes

it possible to remotely switch an FS compressor,

e.g. from a control room, off and on-load. Condi-

tion: "Enable Remote Load" is activated.

See chapter "Configuration / Remote load and off-

load (FS)".

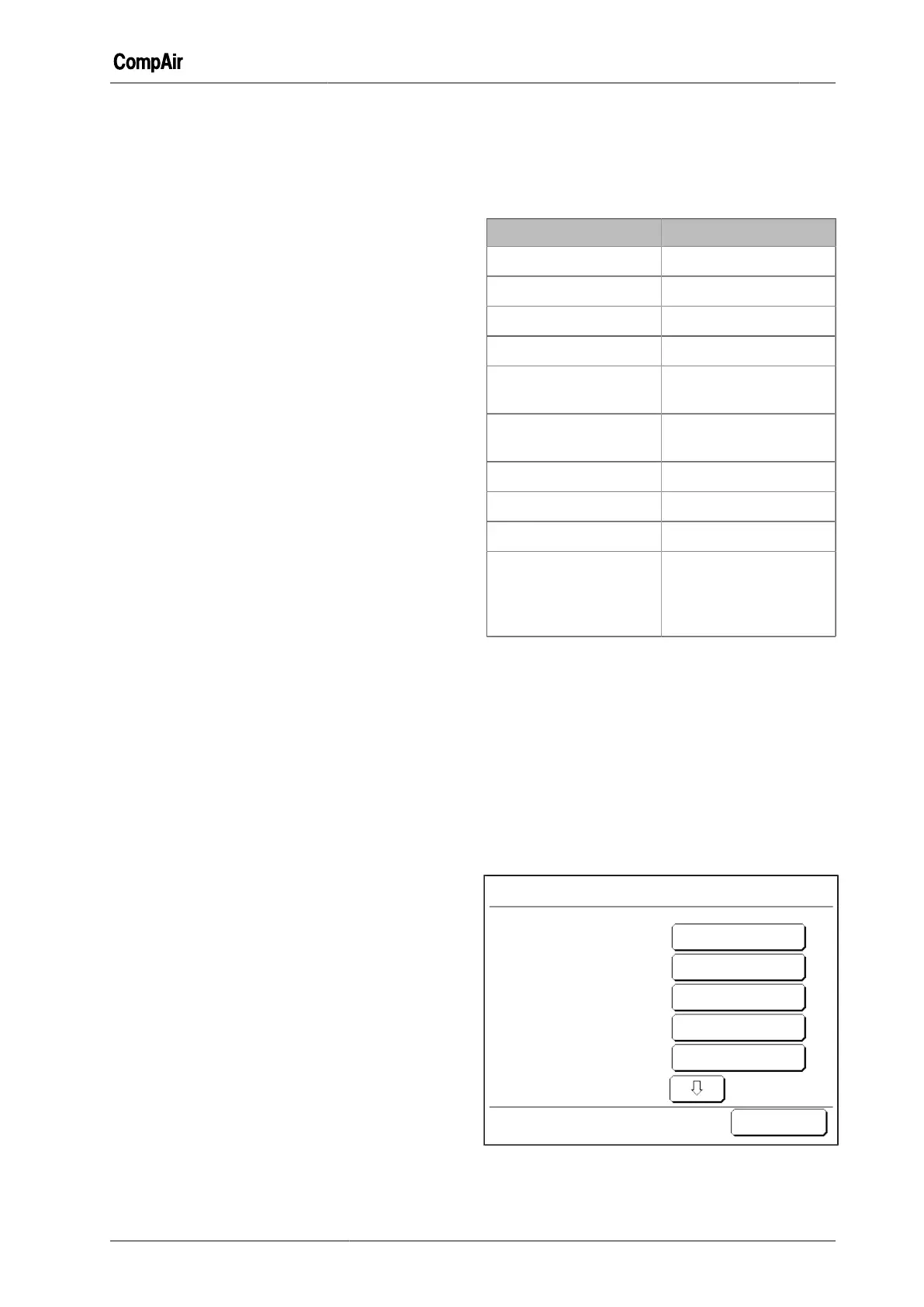

5.5.2.2 Conditions Associated With Program-

mable Inputs

The following table contains a list of conditions

that must be fulfilled before the controller triggers

the allocated event.

Monitoring Condition

External Fault

Time >1 s

External Warning

Time >1 s

Fault Dryer

Time >1 s

Warning Dryer

Time >1 s

Fault Condens. Drain.

Line pressure > 1.0 bar

and time > 250 s

Warn. Condens. Drain

Line pressure > 1.0 bar

and time > 250 s

Phase monitoring

Time >1 s

Air Filter

Time >30 s

Water Filter

Time >30 s

Motor lubrication sys-

tem

Input=High (closed) for

Time > 60 s or input

does not show High

state within 24 hours.

Chart 5-1: Conditions Associated With Programmable

Inputs

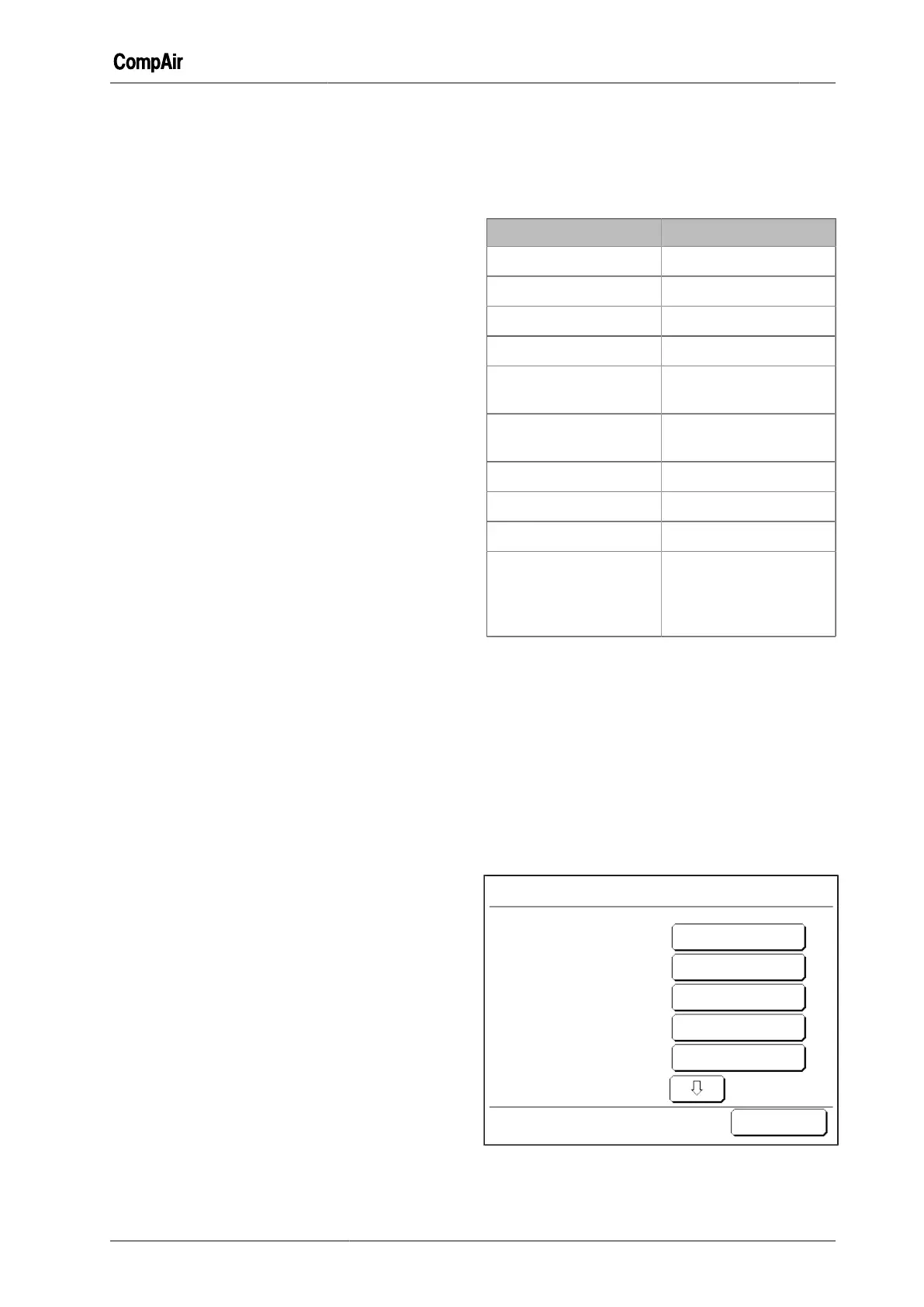

5.5.2.3 Input programming

1

Tap the <Settings> tab.

–

The menu "Settings" appears.

2

Tap the <Programmable Inputs and Outputs>

button.

–

The menu "Programmable Inputs and Out-

puts" appears.

Input 1

Select a Setting

OK

Programmable Inputs and Outputs

Free

Input 2

Free

Input 3

Free

Input 4

Free

Input 5

Free

Fig. 5-18: Menu "Programmable Inputs and Outputs"

Loading...

Loading...