95XF series Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-3

3.4 INSPECTION AND ADJUSTMENT, HEADLIGHT SETTING

Checking the headlight setting

Note:

In view of the required precision we advise you

to use the correct optical and electronic

adjustment equipment, and always follow the

manufacturer’s instructions and advice.

If the c orrect equipment is not available, the

setting of the headlights (dipped beam) can be

checked as follows:

- The dipped beam should have a downward

slant of 1%, which means that when it is

projected on a board or wall at a distance of

10 metres, the light-dark division should be

10 cm below the centre height of the

headlamp.

1. When checking the headlight setting

(dipped beam) the vehicle must carry no

load and the tyres should have the

prescribed tyre pressure.

2. Ensure that the vehicle is standing on a flat

and level surface.

3. Make sure t hat when checking the headlight

setting, the rotary knob for the headlight

adjustment, if available, is in its central “0”

position.

Adjusting the headlight setting

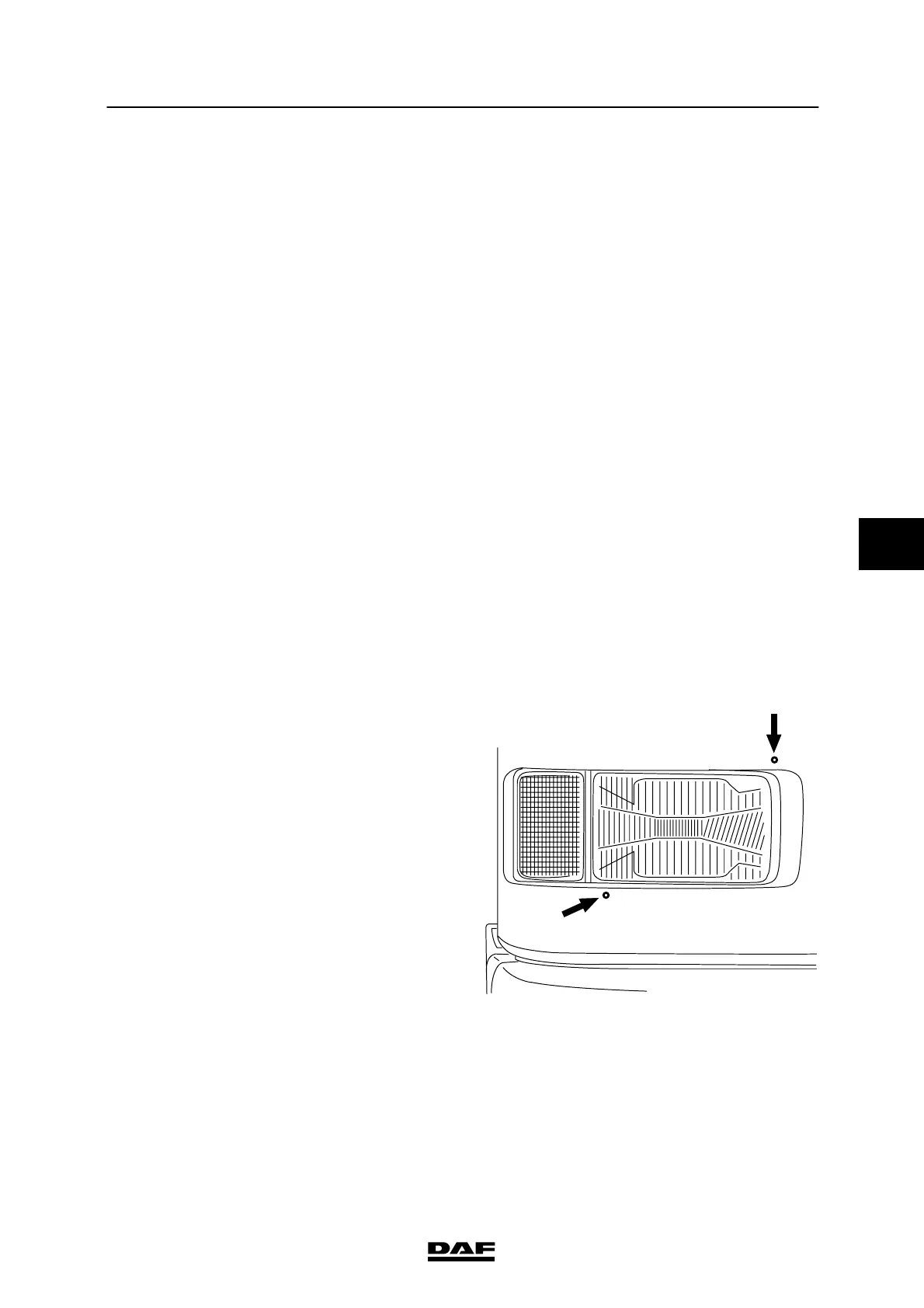

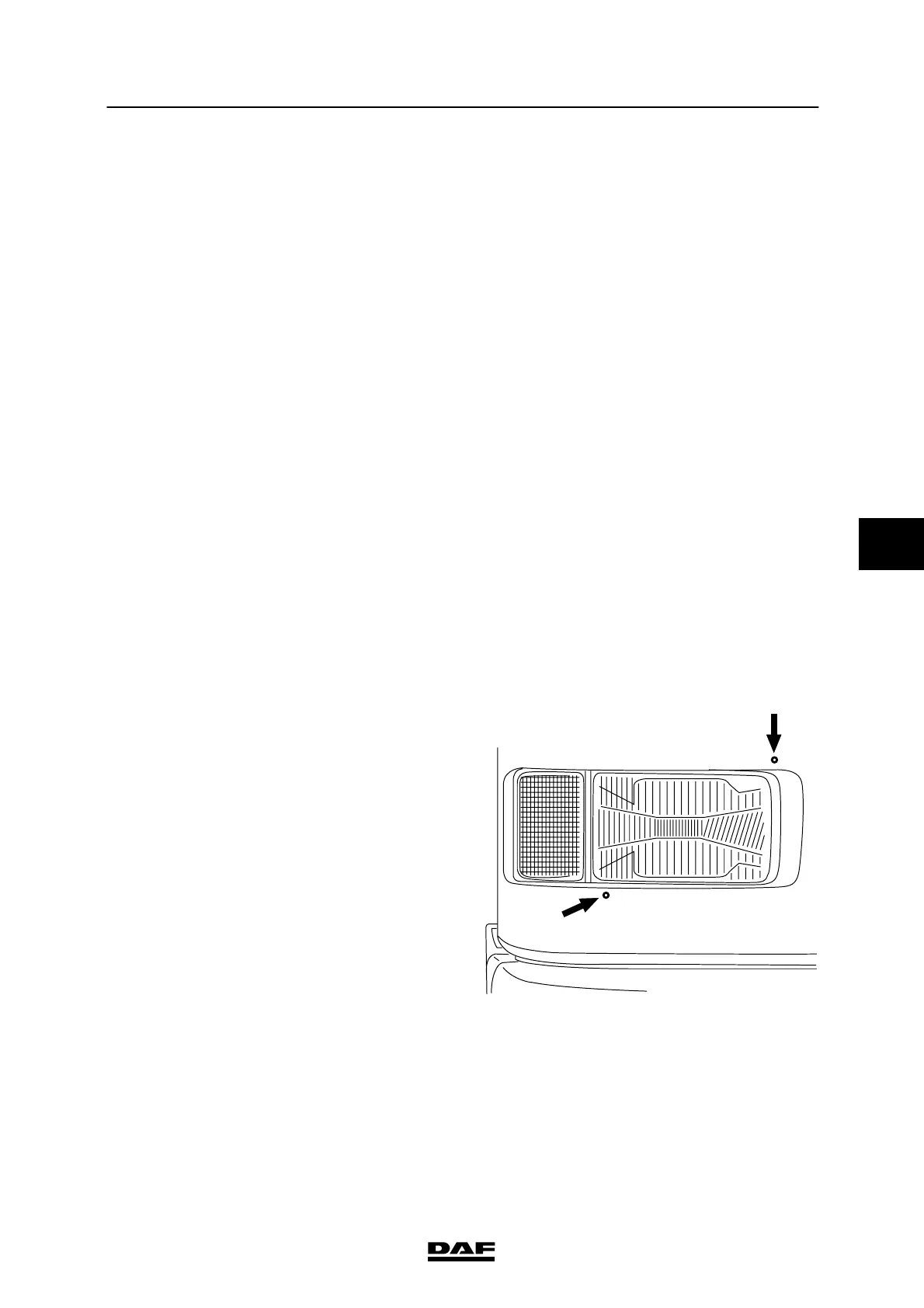

1. Adjust the headlights using two adjusting

bolts which c an be reached through the

openings in the headlight rim.

Adjusting bolt (1) changes the vertical

adjustment of the beam and adjusting

bolt (2) the horizontal adjustment.

K100356

1

2

5

200424

Loading...

Loading...