The one exception is when the Control Temperature Source

is set to None. In this case, the effective Reheat Setpoint is

always set equal the current Discharge Air Cooling Setpoint

Modulating HGRH Control

In the Cooling and Fan Only states, a PI Loop is used

to control the HGRH valve to maintain the discharge air

temperature at the Dehumidication Reheat Setpoint. The PI

Loop is enabled when the unit is in the Cooling or Fan Only

operating state and dehumidication becomes active.

NOTE: When congured for modulating hot gas reheat the

reheat valve is stroked open and then closed every

day at 2:00 AM as long as dehumidication is inactive

and the unit is not in the Cooling operating state at

the time.

Energy Recovery

(See page 57 for more information)

Energy recovery is provided by drawing outside air across half

of an enthalpy wheel and drawing exhaust air across the other

half. Latent and sensible heat is transferred from the hotter,

moister exhaust air to the colder dryer outside air in winter.

Latent and sensible heat is transferred from the hotter more

moist outside air to the cooler dryer exhaust air in summer.

Control consists of starting and stopping an exhaust fan,

modulating the speed of the exhaust fan, starting and stopping

the enthalpy wheel, and optionally controlling the speed of

the enthalpy wheel. The outdoor dampers are controlled in

the normal manner. The current statuses as well as editable

parameters associated with energy recovery are located in the

Energy Rec Setup menu.

Enthalpy Wheel

Normally the enthalpy wheel is turned on whenever the

exhaust fan is running and the outdoor air dampers are at the

minimum position (i.e. the unit is not in the Econo operating

state). The wheel is shut off if the exhaust fan ever turns off or

if the unit enters the Econo operating state and the dampers

are driven more than 3% above the effective minimum outdoor

air position setpoint.

There are however a number of functions that can overridden

normal wheel operation. These include Enthalpy Wheel Frost

Prevention, Enthalpy Wheel Defrost Control and Enthalpy

Wheel Capacity Limiting Control. These override functions are

described in the following sections.

Enthalpy Wheel Frost Prevention

A unit equipped with a return or space humidity sensor includes

a wheel frost prevention function that can be enabled by

setting the Fst Mgmt Meth= parameter to ExhAir. When there

is a threat of frost or condensation on the enthalpy wheel, the

wheel may be slowed down or stopped so that less enthalpy

transfer occurs and frosting or condensation on the enthalpy

wheel is avoided. In this case the frost control is based on an

Intersection Point described as follows:

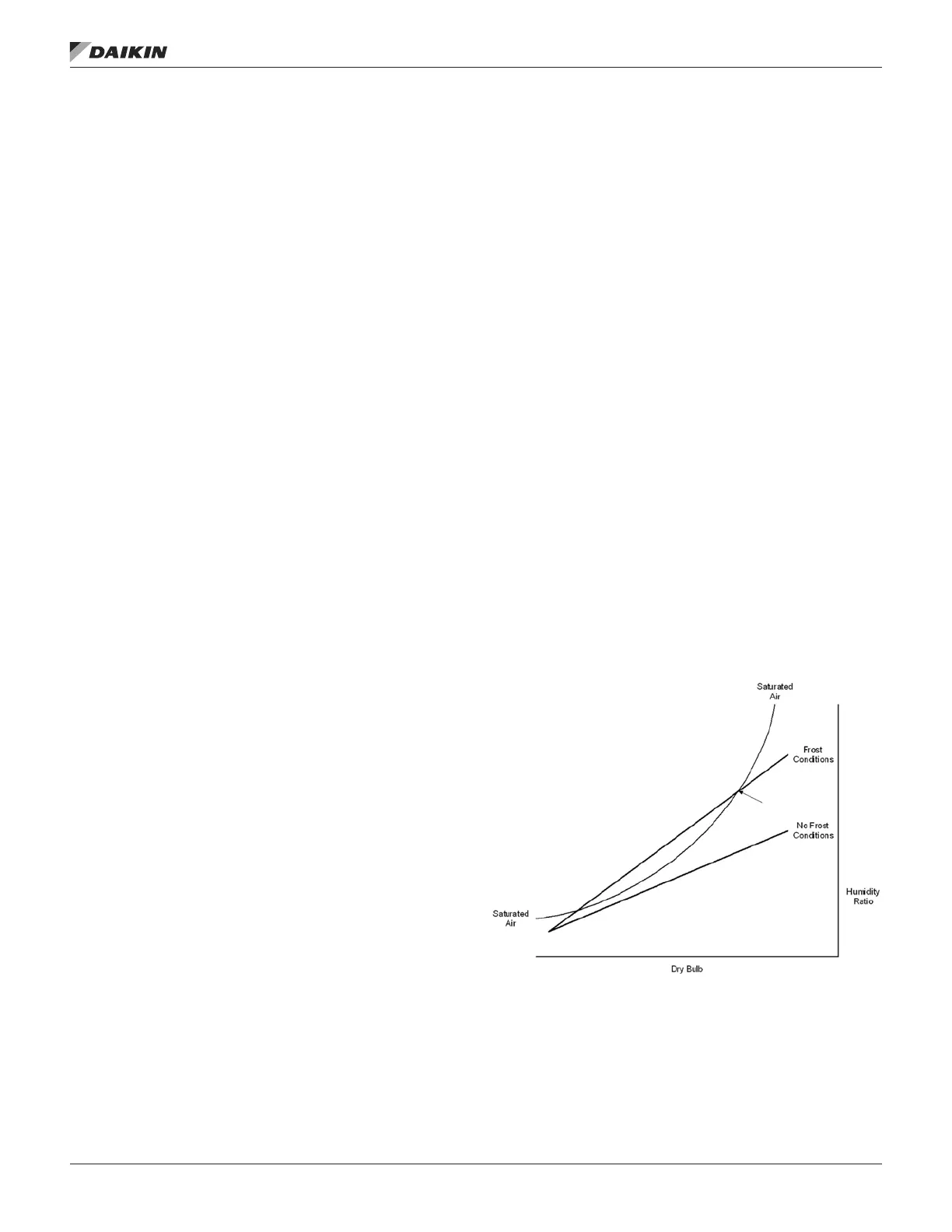

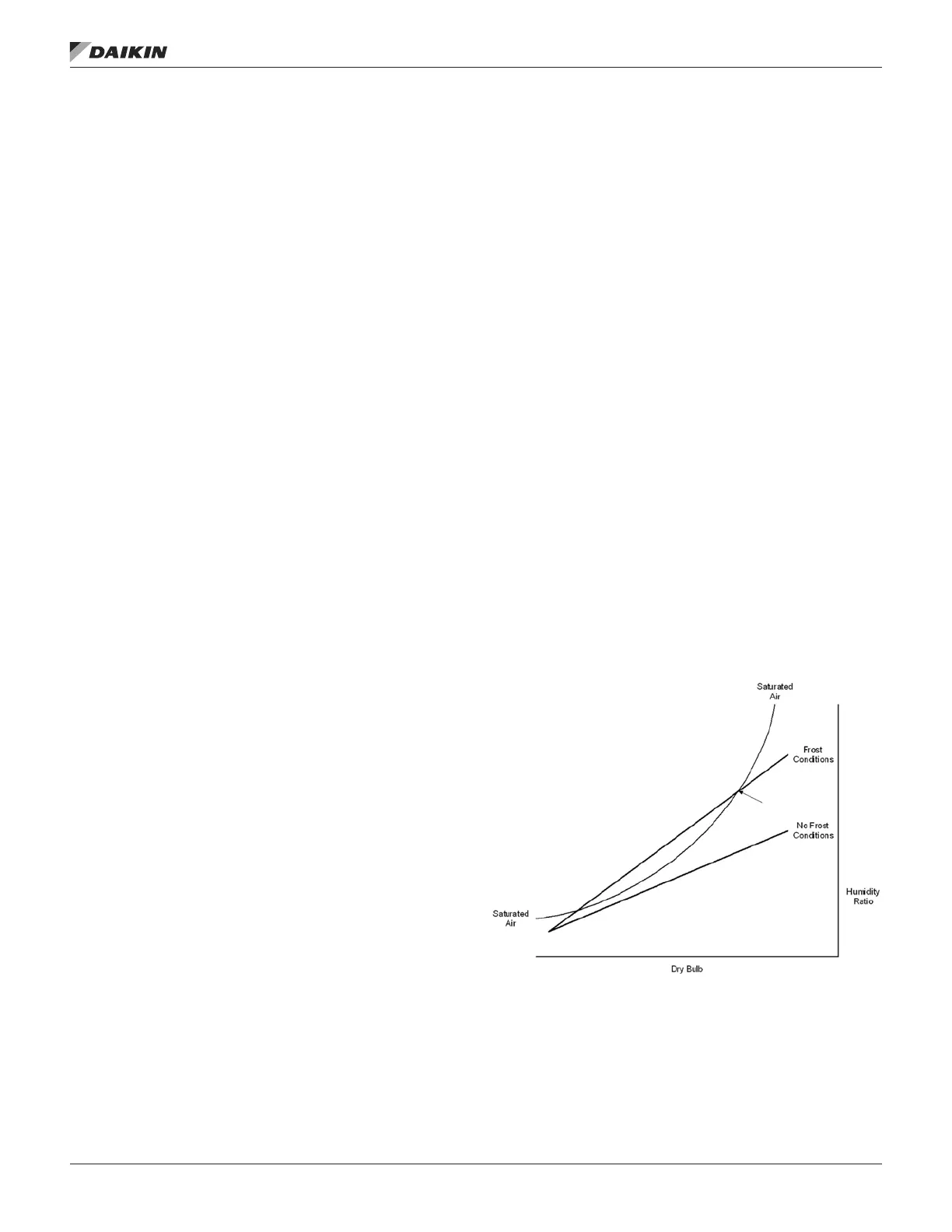

Condensation and frosting can occur on the enthalpy wheel

when the exhaust air leaving the wheel is saturated. This

condition will occur when two lines intersect on a psychometric

chart, and it will not occur when these two lines do not

intersect. One of these lines is the Humidity Ratio versus the

dry bulb for saturated air. The other line is the Humidity Ratio

versus the dry bulb temperature of the exhaust air leaving

the enthalpy wheel. The two ends of this second straight line

on a psychometric chart are the OAT at 95% RH and the

return air temperature at the return air relative humidity. One

line showing frosting conditions and another line showing no

frost conditions are shown on the sketch of a psychometric

chart shown below. A continuous calculation determines if

and at what temperatures these two lines intersect. If they do

intersect they intersect at two points. The higher of the two

points is referred to as the “Intersection Point”. When they do

not intersect, the enthalpy wheel runs at full speed. When they

do intersect, the enthalpy wheel may be slowed or stopped to

maintain the dry bulb temperature of the exhaust air leaving the

enthalpy wheel high enough to eliminate the Intersection Point

and therefore the threat of frosting conditions.

Figure 17: Exhaust Air Psychometric Chart

operator’s guIde

www.DaikinApplied.com 101 OM 1141-3 • MICROTECH UNIT CONTROLLER

Loading...

Loading...