Cooling

(See page 41 for more information)

Entering the Cooling Operating State

The unit enters the Cooling operating state from the Fan Only

operating state when the control temperature rises above the

Occupied Cooling Set Point by more than half the Occupied

Cooling Dead Band and the discharge air temperature is above

the discharge cooling setpoint by more than half the Occupied

Cooling Dead Band. The unit transitions from Cooling to Fan

only when the control temperature falls below the Occupied

Cooling Set Point by more than half the Occupied Cooling

Dead Band. The unit will also transition from the Cooling to Fan

only operating state if Cooling operation is disabled due to OA

ambient lockout.

DAT Control

In the Cooling state, compressors are modulated to maintain

the Discharge Air Temperature at the Discharge Cooling

Setpoint.

Zone Control

In the Cooling state, compressors are turned ON and

modulated to maintain the control temperature at the Occupied

Cooling Setpoint.

When Dehumidication is active, compressors are modulated

to maintain the leaving coil temperature at the minimum leaving

coil setpoint.

Project Ahead

This section describes the Projected Control Temperature

used to turn on and off stages of heating and cooling for Zone

Control units. It is not used in DAT Control units.

In Zone Control cooling and heating operation, the Projected

Control Temperature, reduces overshoot as the zone

temperature approaches a setpoint after startup. It does this

by causing stages to stop increasing before the actual control

temperature reaches the setpoint. The rate of change of the

control temperature is calculated once per minute by the

controller and equals the change during the last sixty seconds.

This rate of change is multiplied by the Effective Project Ahead

Time and is added to the current control temperature. The rate

of change may be negative or positive so the Projected Control

Temperature may be higher or lower than the actual control

temperature. This value, the Projected Control Temperature, is

the temperature that would exist after the Project Ahead Time

passes if the control temperature were to continue to change

at the same rate for the Effective Project Ahead Time. The

Effective Project Ahead Time is set equal to the Cooling Project

Ahead Time when the unit is in the Cooling state. The Effective

Project Ahead Time is set equal to the Heating Project Ahead

Time when the unit is in the Heating state. It is set equal to

zero under all other conditions causing the Projected Control

Temperature to equal the actual control temperature

Discharge Air Temperature Setpoint

Reset - Cooling

The Cooling DAT Setpoint may be reset for units with DAT

Cooling Control. The reset type may be set to one of the

following:

• None: Discharge Cooling Spt is user adjustable

• Network: Discharge Cooling Spt is equal to the Network

DAT Clg Setpoint when it is valid

• Space: Discharge Cooling Spt is based on the Space

Sensor

• Return: Discharge Cooling Spt is based on the Return Air

Sensor

• OAT: Discharge Cooling Spt is based on the Outdoor Air

Temperature

• Ext mA: Discharge Cooling Spt is determined by a 0-20

mA signal

• Ext V: Discharge Cooling Spt is determined by a 0-10

VDC signal

• Airow: Discharge Cooling Spt is based on the airow as

indicated by the variable frequency drive speed

Reset reverts from Return to None when a Return Air Sensor

opens or shorts. Reset reverts from Space to None when a

Space Sensor opens or shorts. Reset reverts from OAT to

None when an Outdoor Air Sensor opens or shorts.

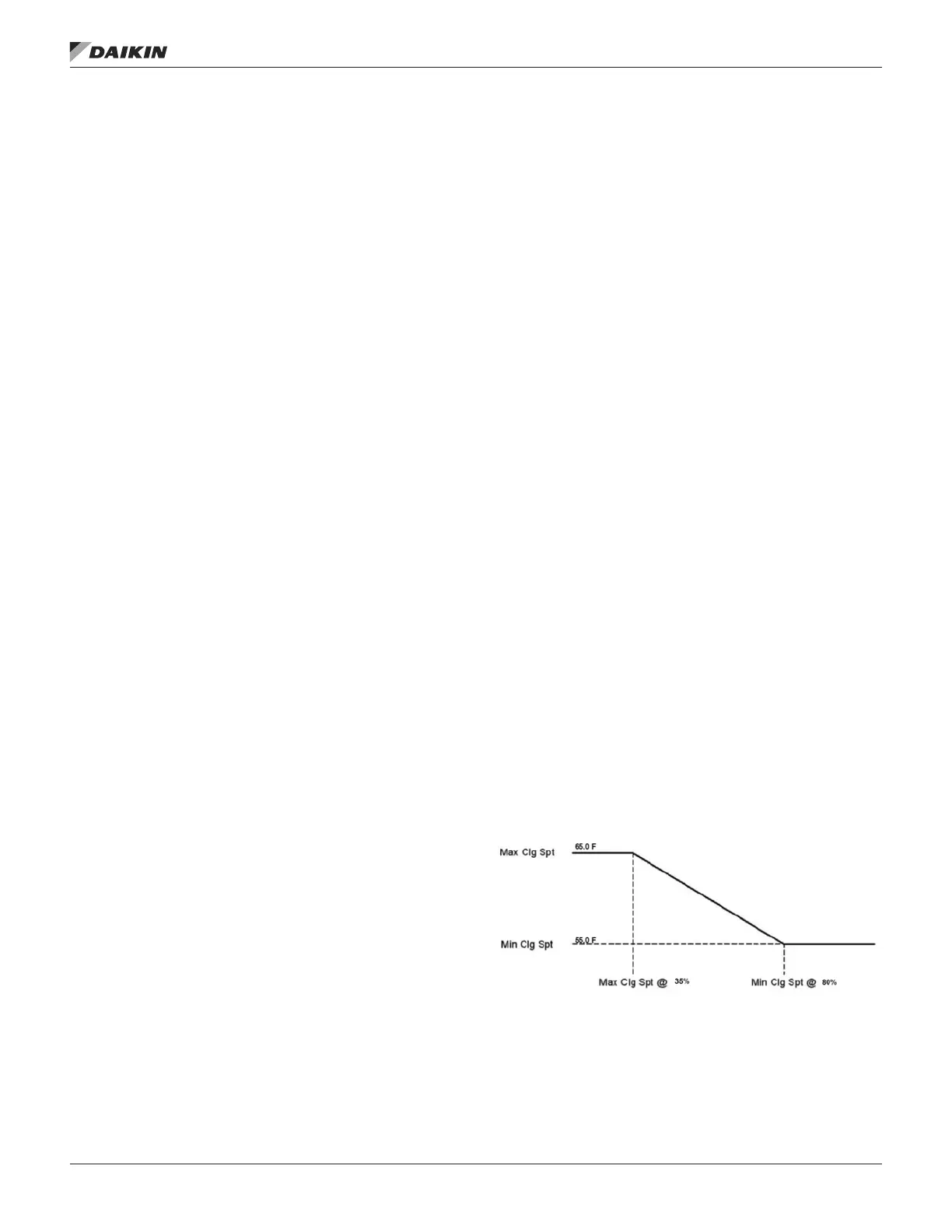

When Space, Return, OAT, Airow, Ext mA, or Ext V is

selected, the Discharge Cooling Spt equals the Max Clg Spt

when the selected value equals the Max Clg Spt @ value.

Similarly, the Discharge Cooling Spt equals the Min Clg Spt

when the selected value equals the Min Clg Spt @ value.

When Space, Return, OAT, or Airow is selected, the reset

schedule should be set so that the DAT Cooling setpoint

decreases as the selected temperature increases as shown in

the graph below.

Figure 19: Cooling Setpoint

operator’s guIde

www.DaikinApplied.com 107 OM 1141-3 • MICROTECH UNIT CONTROLLER

Loading...

Loading...