unIt confIguratIon setup

Unit Conguration Setup Menu

After the main control board application software is loaded

into the MCB, it must be “congured” for the specic

control application. This consists of setting the value of 25

conguration variables within the MCB. These variables dene

things such as the type of cooling, number of compressors and

cooling stages and the type of heat. If all of these items are not

set appropriately for the specic unit, the unit will not function

properly. The correct settings for these parameters are dened

for a given unit by the unit “Software Conguration Code.”

The “Software Conguration Code” consists of a 29-character

string of numbers and letters. The code can be found on the

Unit Software Identication Label located on the back side of

the control panel door.

Table 53 lists the conguration code variables including the

position within the code, description of the parameter, and the

applicable settings for each. The default values are shown

in bold font. The unit is congured at the factory however

may also be congured in the eld by accessing the Unit

Conguration Menu. Once changes have been made to the

Unit Conguration Menu, the Apply Changes ag must be

changed from no to yes in order for the controller to recognize

the changes. Setting the Apply Changes ag to yes will

automatically rest the controller.

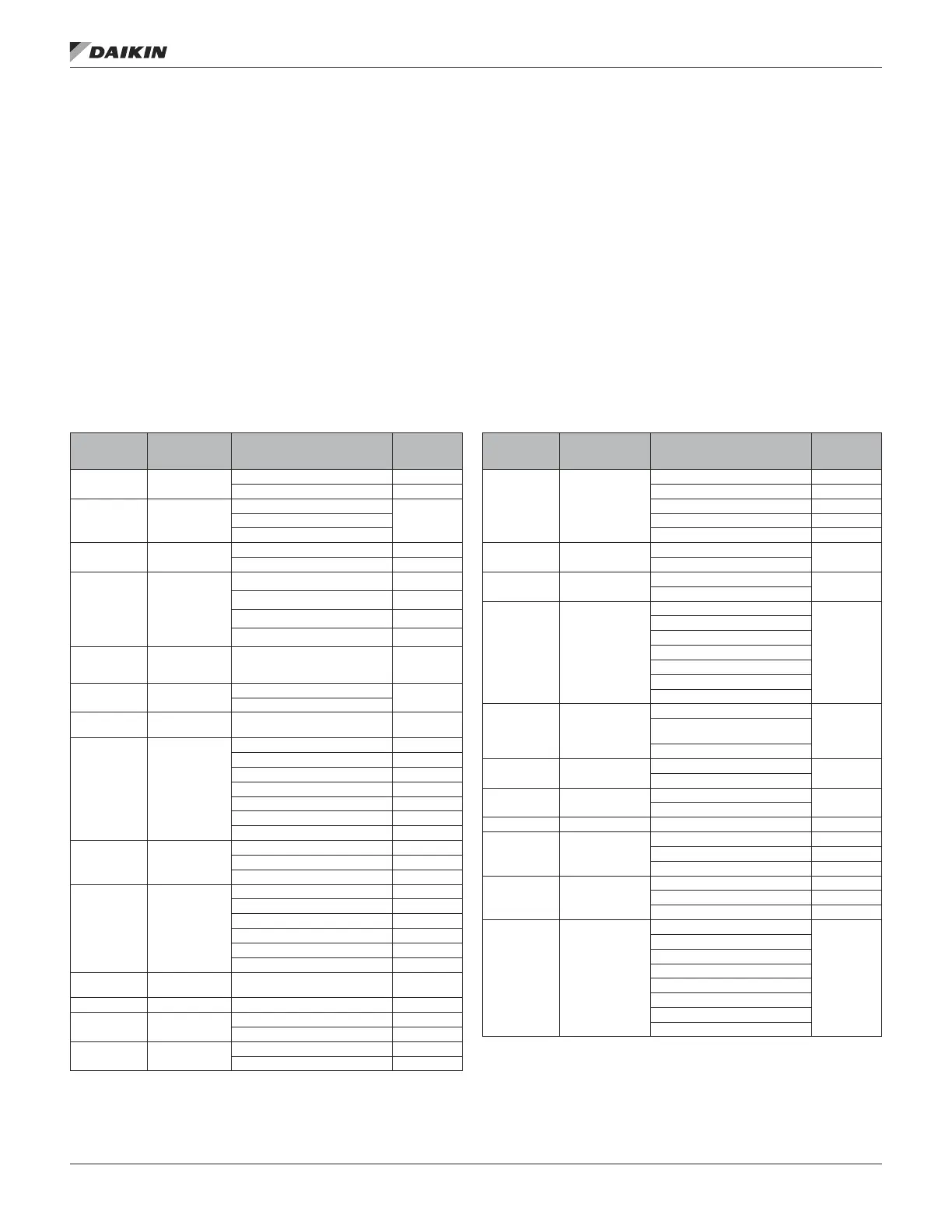

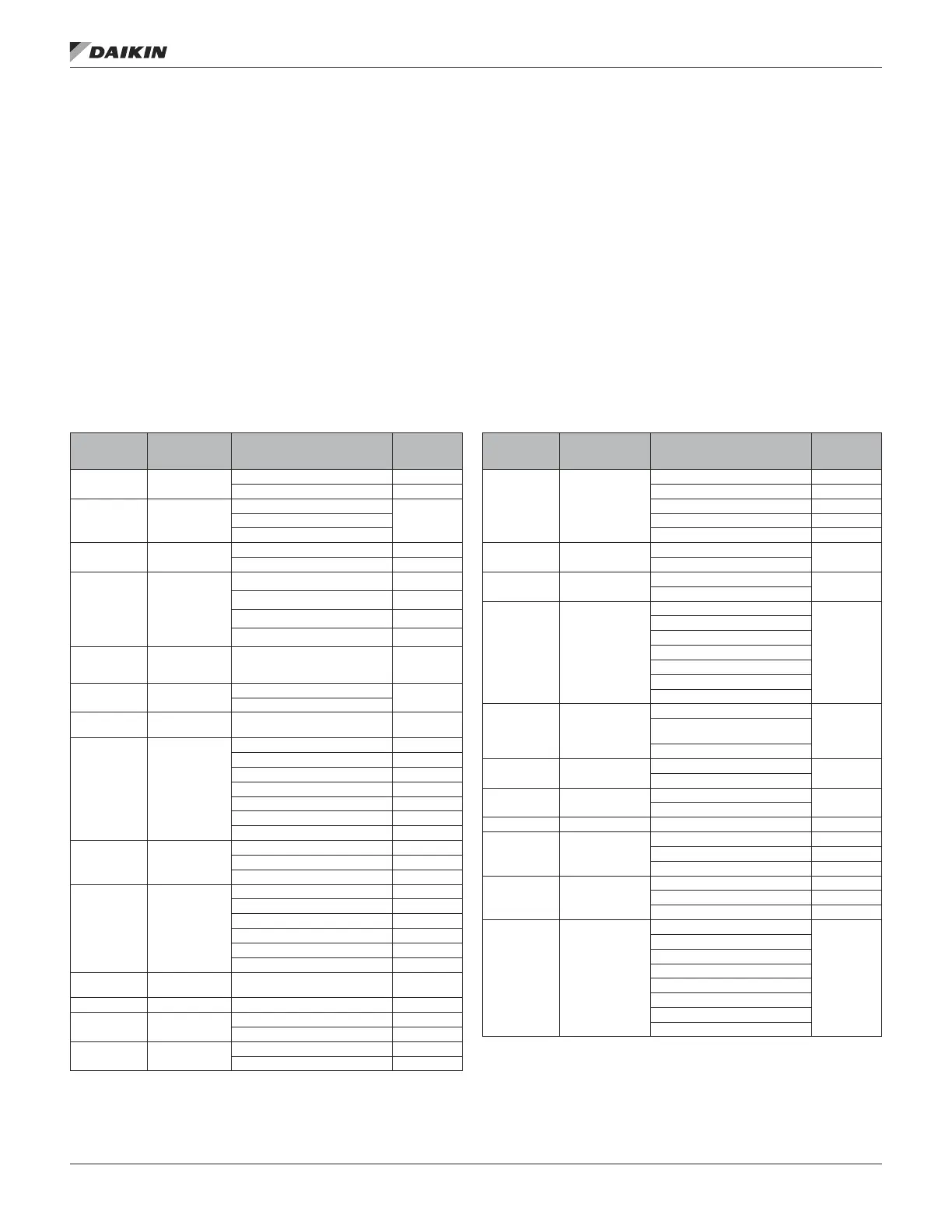

Table 53: Unit Conguration Menu

Conguration

Code

Position

Description Values (Default in Bold)

DPS

Applicability

1 Unit Type

3=Rebel Cool Only (DPS) ●

4=Rebel Heat Pump (DPH) ●

2 Control Type

0=Zone Control

●1=DAT Control

2=1ZoneVAV

3 Cooling Type

0= None NA

4=Inverter Compressorized Clg ●

4

Compressorized

Cooling

Conguration

0=None NA

1=Generic Condenser NA

L=1INV/1Circ ●

M=1INV/1STD/1Circ ●

5

Generic

Condenser

Stages

1 – 8 Stages (Default = 8) NA

6 Low Ambient

0= No

NA

1= Yes

7

Condenser

Control

8=INV ●

8 Damper Type

0=None ●

1=Single Position 30% ●

2=Single Position 100% ●

3=Economizer Airside ●

5=100%OA_DOAS ●

6=AirEcon_DOAS ●

7=30%_DOAS ●

9 OA Flow Station

0=None ●

5=Generic Flow Station ●

6=Generic Flow Station w/CO2 ●

10 Heating Type

0=None ●

1=F&BP Control NA

2=Staged ●

5=Steam or Hot Water ●

6=SCR Electric ●

7=MPSLoGas ●

11

Max Heating

Stages

1-4 Stages (Default = 1) ●

12, 13, 14 Max Heat Rise Three Digits (Default = 100) ●

15

Supply Fan

Type

6=EBMVAV ●

7=EBMCAV ●

16

Return Fan

Type

F=EBMVAV ●

G=EBMCAV ●

Conguration

Code

Position

Description Values (Default in Bold)

DPS

Applicability

17

Return/Exhaust

Fan Capacity

Control Method

0=None ●

1=Tracking NA

2=Building Pressure ●

3=Speed/Network ●

4=OADamper ●

18

Second Duct

Pressure Sensor

0=No

NA

1= Yes

19

Entering Fan

Temp Sensor

0=No

●

1=Yes

20 Energy Recovery

0=None

●

1=ConstSpdWhl/NoRH

2=VarSpdWhl/Danfoss

3=VarSpdWhl/MD2

4=VarSpdWhl/MD3

5=VarSpdWhl/ABB

6=ConstSpdWhl/wRH

21

Cooling Circuit

Type

0=Individual

NA

1=2,3 or 4 Circ. Water

Condenser

2=2 Circ. Air Condenser

22

Head Pressure

Control

0=No

NA

1=Yes

23

Bypass Valve

Control

0=Slave

NA

1=Bypass

24, 25, 26 Unit Size Three digits (Default 050) ●

27 Refrigerant Type

0=R22 NA

1=R407C NA

2=R410A ●

28 Reheat Type

0=None ●

2=ModHG ●

3=StdHtRht ●

29 Unit Voltage

0=208/60Hz

●

1=230/60Hz

2=460/60Hz

3=575/60Hz

4=208/50Hz

5=230/50Hz

6=460/50Hz

7=575/50Hz

unIt confIguratIon setup

www.DaikinApplied.com 69 OM 1141-3 • MICROTECH UNIT CONTROLLER

Loading...

Loading...