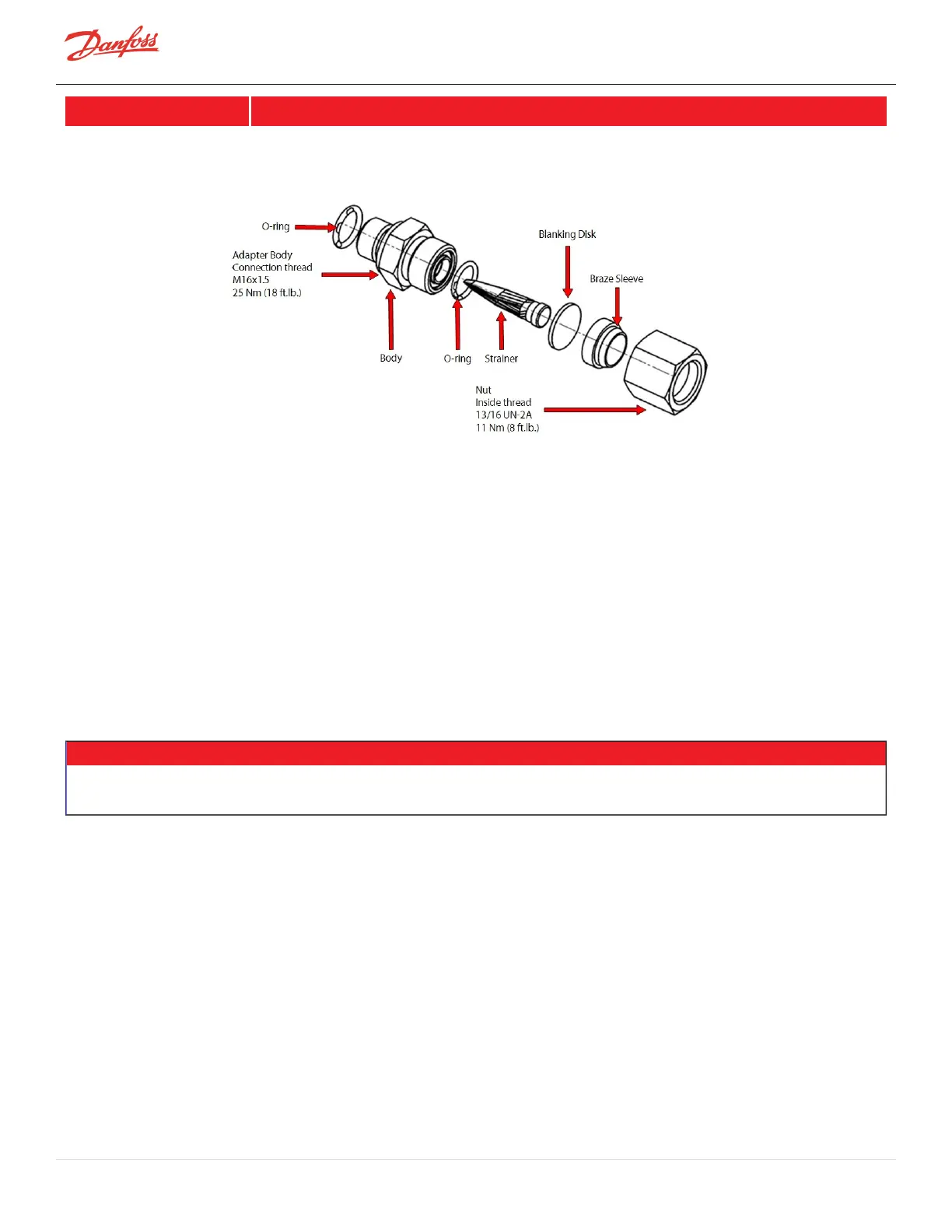

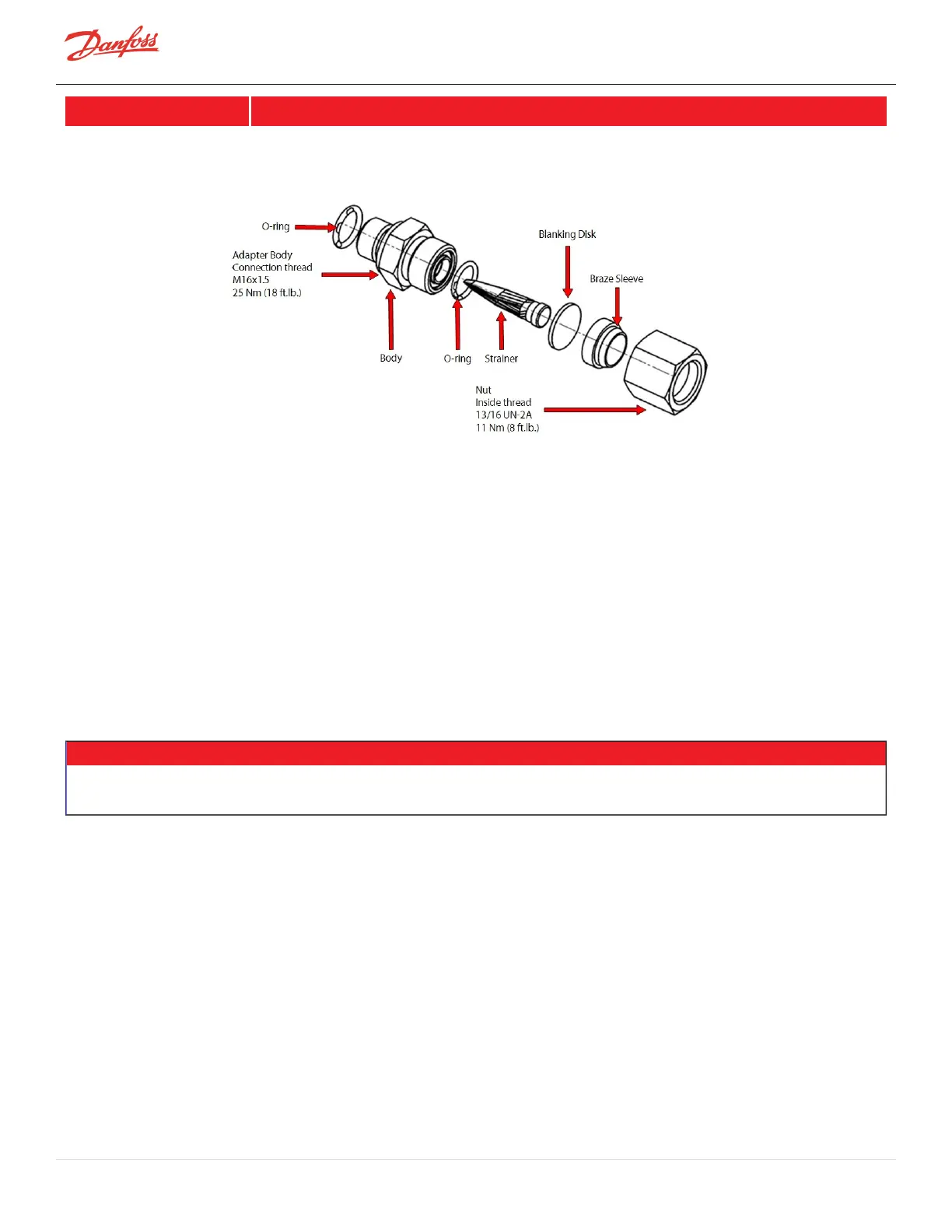

Component Notes

Nut Tubeconnectionthreadis13/16-16UN-2A.StrainerrecessisØ9.5.

Figure 3-3 Motor Cooling Fitting

Flexible Line

1. Iftheconnectionisaflexiblehoseto3/8or1/2inchflare,theentirehosewillrequirereplacementwith

thecurrentstyle.

2. Isolatethecompressorandrecovertherefrigerantaccordingtoindustrystandards.RefertoSection3.1

RefrigerantContainmentonpage41.

3. SourceappropriateOEMspecifiedandprocuredflexibleline.

4. Removethenutfromtheconnectionfittingbody.Discardtheblankingdisc,nut,andbrazesleeve.

5. BeforeinstallationoftheOEMsuppliedflexibleline,inspecttheO-ringfacetoensureitiscleanand

freefromscratchesorotherdamage.LightlycoatO-ringlubeontheO-ringfaceofthelineandinstall

usingtwo(2)wrenches;onetoholdbodyoffittingandonetotightenthenut.Thisisdonetoprevent

overtorqueingthefittinginthecompressorhousing.

NOTE

FlexiblelinesarenotsuppliedbyDanfossLLC.SelectionofappropriatehoseandfittingistheresponsibilityofOEM/installer.This

informationisreadilyavailablefromvarioussources.

Rigid 1/2 inch copper connection

1. Iftheconnectionis1/2inchrigidcopper,alengthof1/2inchcoppermustbebrazedintothebraze

sleeve.

2. Isolatethecompressorandrecovertherefrigerantaccordingtoindustrystandards.RefertoSection3.1

RefrigerantContainment.

3. Removethenutfromtheconnection-fittingbody.Discardtheblankingdisc.Slidethenutoverthe

pipe,threadedsidetowardtheoutlet.

4. Locatethebrazesleeveandclean.Ensureremovalofalloilandsurfacedebris.BrazeaspertheOEM

standardprocessforcopper/steeljoint.

5. Placeanappropriatelengthof1/2inchcoppertubeintothebrazesleeve.Pretreat/fluxjointareaas

pertheOEMstandardprocedure.Brazethepipetothesleeveensuringthenutcanbefittedafter

brazingorotherwisepositionasrequired.Cleanfluxandanyexcessfillerfromjoint.

Page 44 of 294 - M-SV-001-EN Rev. H 1/23/2023

Loading...

Loading...