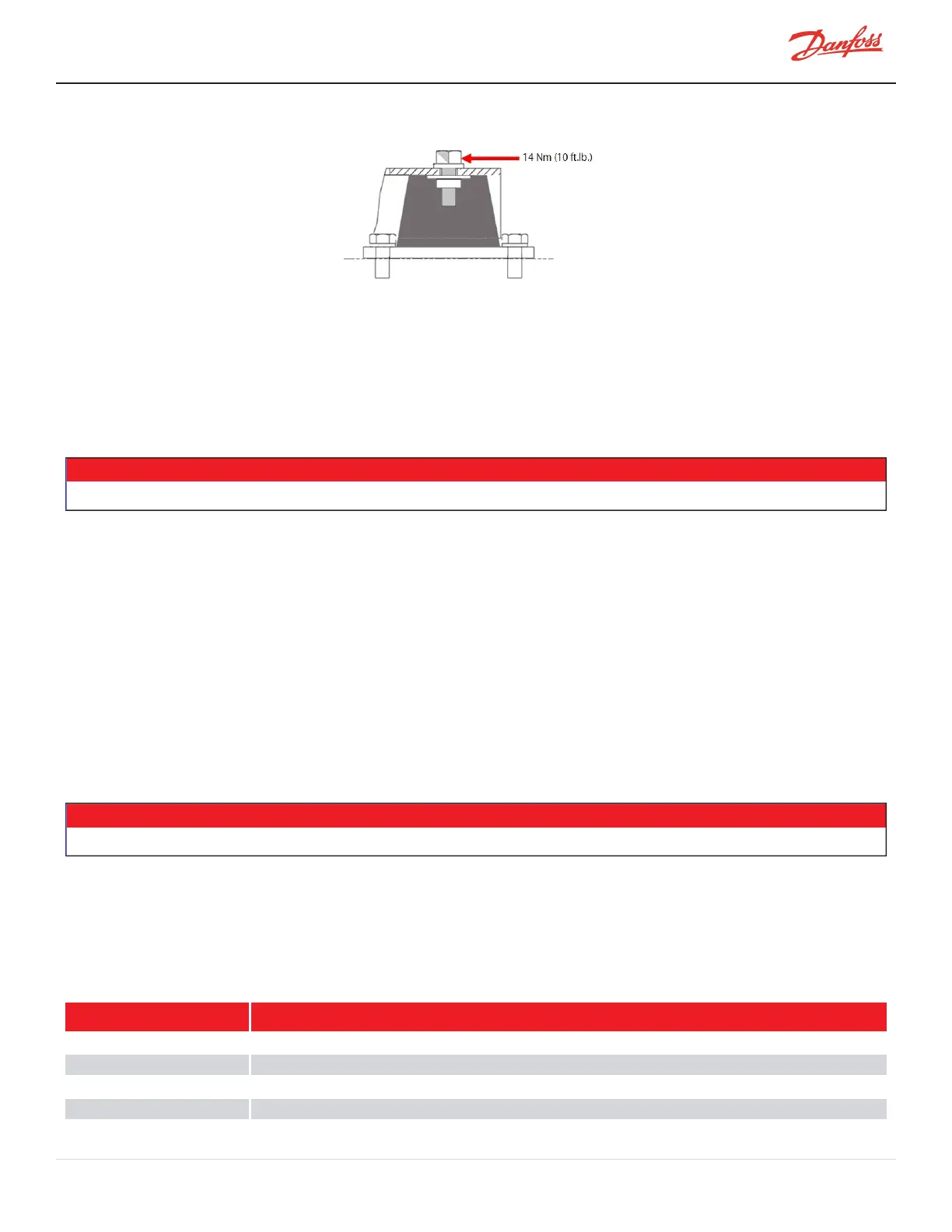

Figure 3-2 Compressor Mounting Fasteners

15. Torquethemotorcoolinglineconnection(Nut)to11Nm(8ft.lb.).

16. RemovetheServiceSideCover.RefertoSection4.1.3.1ServiceSideCoverRemovalandInstallationon

page54.

17. InstalltheI/Ostrainrelieftothecompressorhousing.

18. ConnectthecompressorI/OcabletotheBackplaneI/Oconnector(J7).

19. InstalltheServiceSideCover.RefertoSection4.1.3.1ServiceSideCoverRemovalandInstallationon

page54.

• • •DANGER! • • •

EnsurethatelectricalpowerisisolatedfromtheACmainscablesbeforehandlingthecables.

20. RemovetheMainsInputCover.RefertoSection4.1.1.1MainsInputCoverRemovalandInstallationon

page52.

21. ConnectthecableglandthatsecurestheMainsInputcableconduittotheMainsInputbracket.

22. InstalltheMainsInputgroundwiretothegroundpostandtorquethetopnutto10Nm(7ft.lb.).

23. AttachtheACmainscablestotheterminalsandtorquetospecification.

l

TTS300/TGS230Compressors-20Nm(15ft.lb.)

l

AllCompressors(excludingTT300/TG230)-21Nm(15ft.lb.)

24. InstalltheMainsInputCover.RefertoSection4.1.1.1MainsInputCoverRemovalandInstallationon

page52.

25. Leaktestandevacuateinaccordancewithstandardindustrypractices.

26. Returnthecompressortonormaloperation.

Changestothecompressorsoftwaresettingsmaybenecessarytoalignwiththechillerrequirements.

3.4 Compressor Replacement Considerations for Motor Cooling Adapter

ThehousingconnectionsealisanISOstandardO-ringsealandtheexternalpipeworkconnectionisanORFS.In

addition,thelinesizeis1/2inchforallmodelsandthefittingincludesabuilt-in(removable)strainer.

RefertoFigure3-3MotorCoolingFittingonpage44.

Table 3-1 Cooling Adapter Detail

Component Notes

Body IncludesbothO-rings-BodytocompressorhousingthreadisM16x1.5.

Strainer -

BlankingDisk -

1/2"BrazeSleeve Steelforallconnecting1/2coppertube

M-SV-001-EN Rev. H-1/23/2023 Page 43 of 294

Loading...

Loading...