13. InspecttheIGVHousingassemblyforresidue/contaminationorforeignobjects.

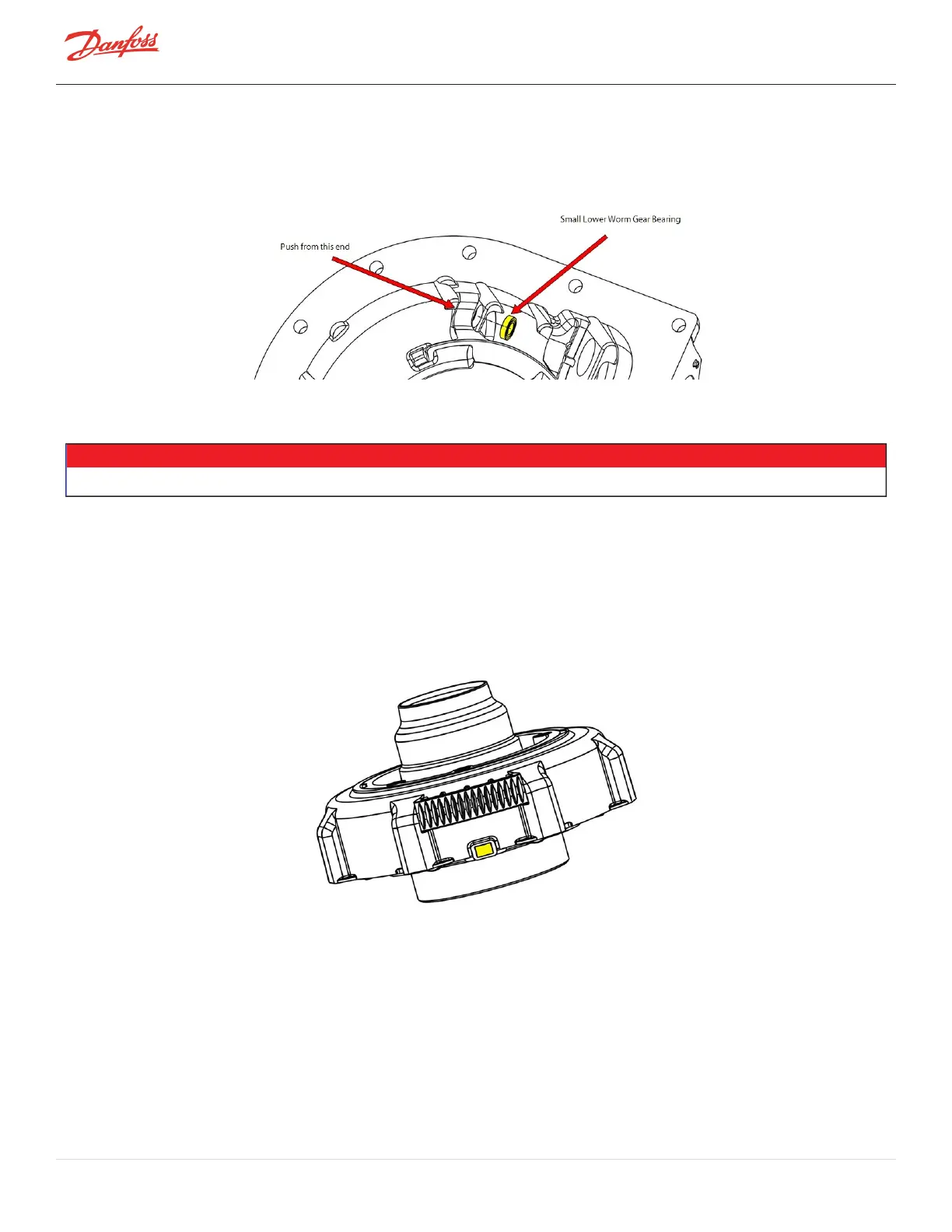

14. Removethesmalllowerwormgearbearingfromthehousing.Performthisstepbypushingthe

bearingoutfromtheportbelowthebearing.RefertoFigure4-62SmallWormGearBearing.

Figure 4-62 Small Worm Gear Bearing

4.9.3.3 IGV Assembly Installation

• • • CAUTION • • •

FittingincorrectIGVcomponentsforthespecificcompressormodelwillresultinphysicaldamagetothecompressor.

1. Ensurethatallcomponentsandthreadsareclear,clean,andoilfree.

2. Installthelower(small)wormgearbearingintothehousing.Thismayrequireaverylighttapwitha

hammer.Ensurethelowerwormgearbearingisfullyseatedintothehousing.RefertoFigure4-62

SmallWormGearBearing.

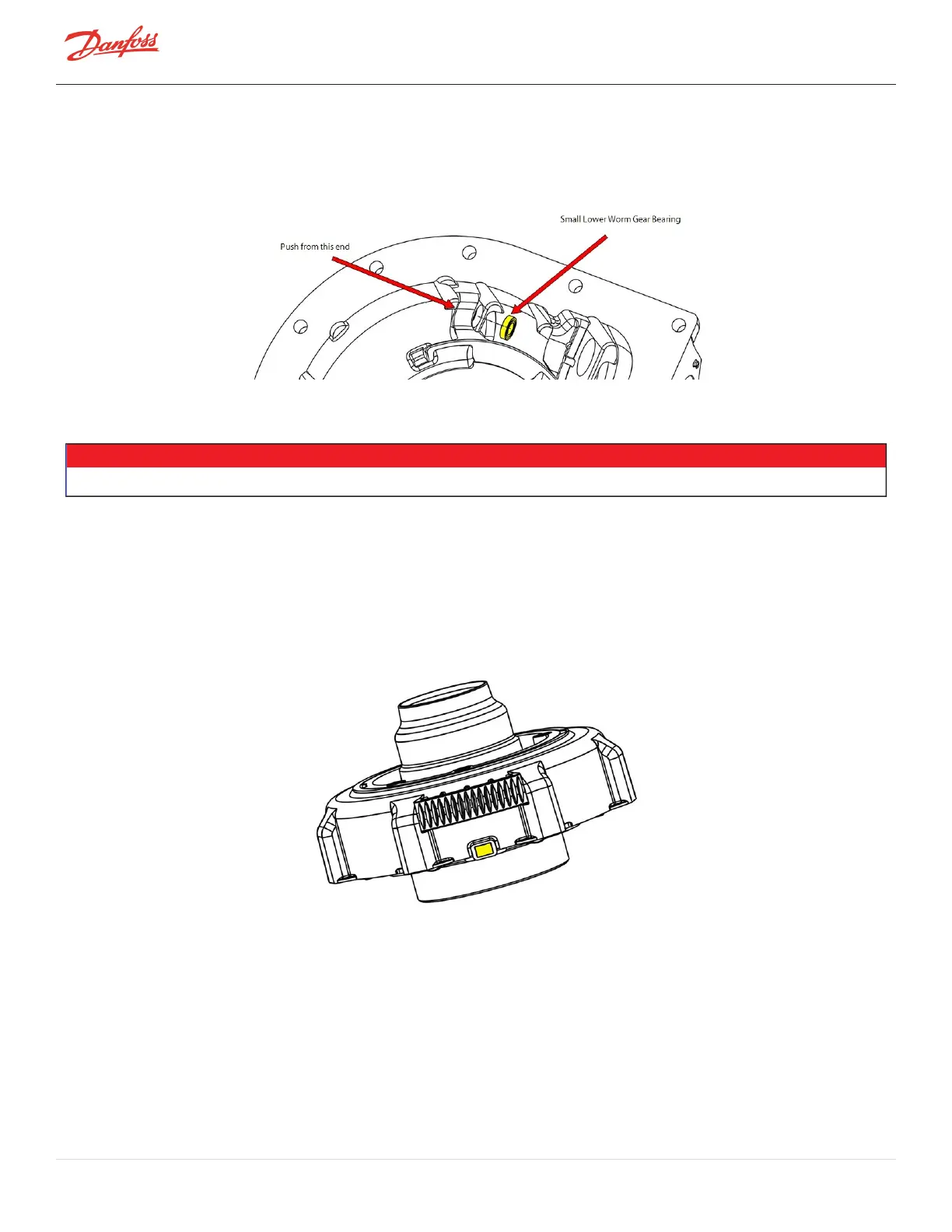

3. EnsuretheIGVpositionindicatormagnetisinplaceintheIGVThroatassembly.RefertoFigure4-63

IGVPositionIndicatorMagnet.

Figure 4-63 IGV Position Indicator Magnet

4. PlacetheIGVThroatassemblyintotheIGVHousingorientatingtheIGVThroatthreadsdirectlybelow

theIGVMotorMount.

5. Addone(1)dropofthreadlocker(Loctite243blueorequivalent)totheIGVThroatfastenerthreads

andinstall.Torqueto5Nm(44in.lb.).

6. Rotatetheouterringofthedriveassemblyandensurethattheguidevanesmovefreely.Theassembly

mustrotateoveraspanwherethevanesareopen(perpendiculartogasflow)andfullyclosed.

7. Fittheupper(large)bearingtothewormgearandinstallthesnapring.RefertoFigure4-60Large

WormGearBearingonpage89.

Page 90 of 294 - M-SV-001-EN Rev. H 1/23/2023

Loading...

Loading...