3.24 Parameters 27-** Cascade CTL Option

Parameter group 27-** Cascade CTL Option is available if 1

of the following conditions is met:

•

VLT

®

Extended Cascade Controller MCO 101 is

installed.

•

VLT

®

Advanced Cascade Controller MCO 102 is

installed.

•

The frequency converter was ordered with the

type code LXX1.

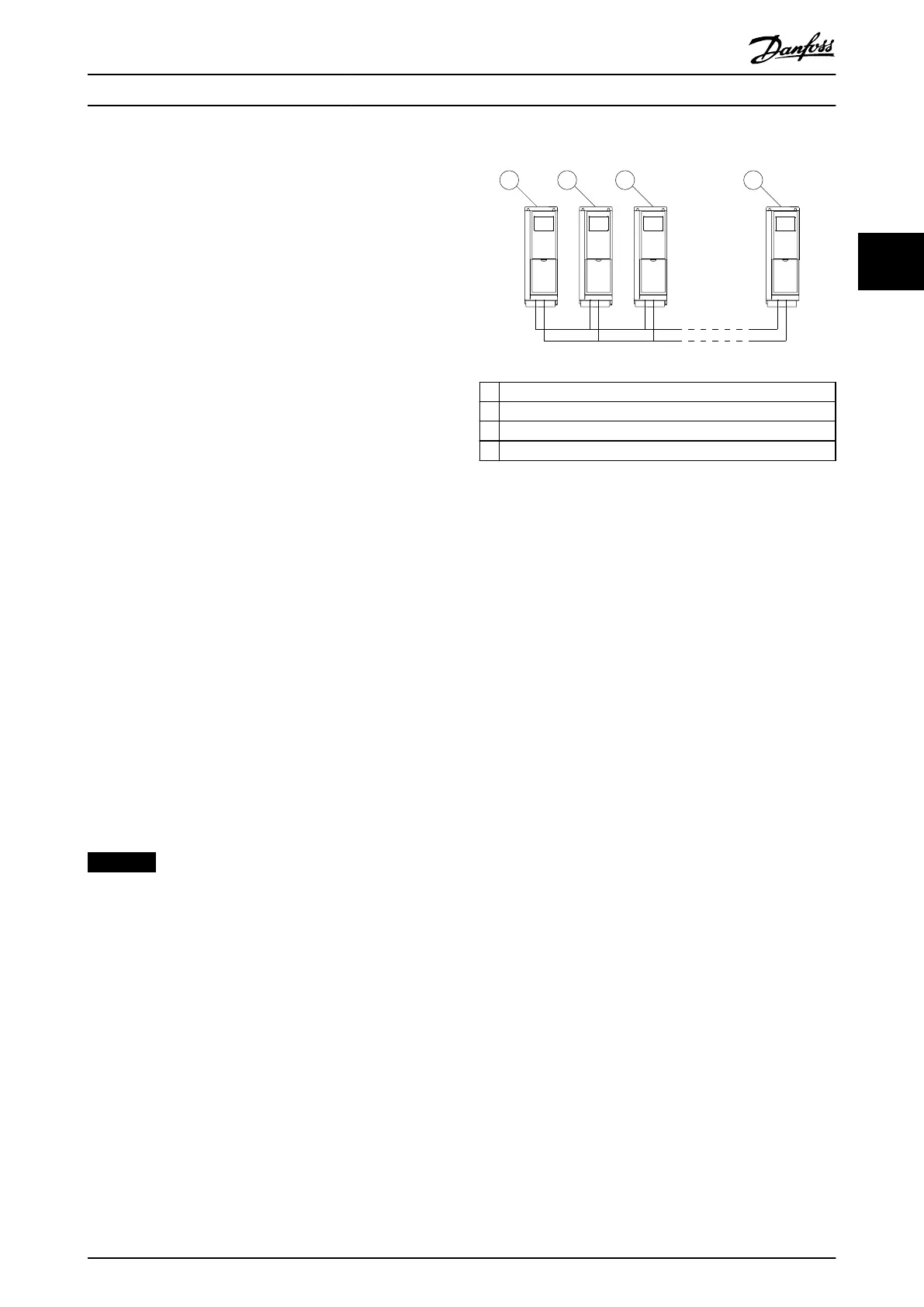

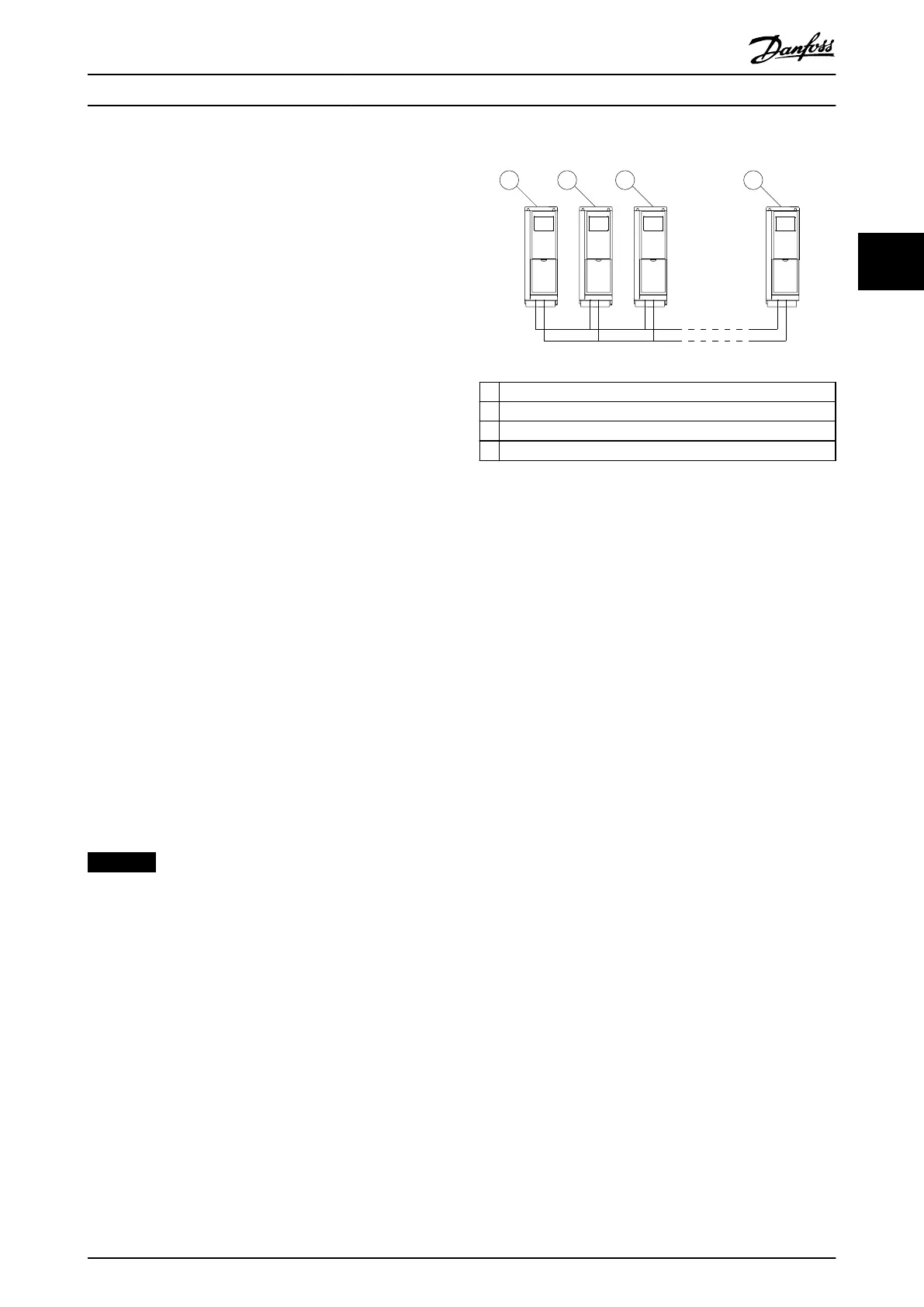

Relay wiring conguration using MCO 101 or MCO 102

For a detailed description of commissioning for mixed

pump and master/slave applications (using relay

operation), refer to VLT

®

Cascade Controller Options MCO

101/102 Operating Instructions.

Serial communication wiring conguration

The serial communication wiring conguration supports

the master/slave cascade controller set-up controlling up to

8 pumps in total.

At least 1 of the frequency converters in the set-up must

have parameter group 27-** Cascade CTL Option enabled.

That enables option Modbus CASCADE Master in

parameter 8-30 Protocol.

The frequency converter with the lowest address and the

cascade controller capability is set as the primary master.

The remaining frequency converters must be addressed

with a unique address or forward-running number.

For slave frequency converters, option Modbus RTU in

parameter 8-30 Protocol has to be set. Reaction at

communication loss can be set in parameter 8-03 Control

Timeout Time and parameter 8-04 Control Timeout Function.

Apply this setting to all frequency converters in the

system.

This

conguration only supports the master/slave mode.

NOTICE

Terminate the RS485 bus with a resistor at both ends.

For this purpose, set switch S801 on the control card to

ON.

68 69

1 2 3 4

68 69 68 69 68 69

e30bg296.10

1 Primary master 1

2 Slave 1

3 Slave 2

4 Slave X (up to 7 slaves)

Illustration 3.95 Serial Communication Wiring

3.24.1 Master/Slave Conguration

The master/slave cascade control mode oers the best

performance, the most precise control, and maximum

energy savings. This mode controls multiple equally sized

pumps in parallel, running all pumps at the same speed

and stages the pumps on and o according to system

requirements.

Compared to the closed-loop cascade control, staging and

destaging decisions are made based on the speed

calculated by frequency converters instead of feedback.

Set the stage-on and stage-o speed according to the

system requirements to obtain the highest energy saving.

In the master/slave conguration, the master frequency

converter is running in closed loop, and the slave

frequency converters are running in open loop. All slave

frequency converters are connected to mains and the

motors in the same way as the master frequency converter.

In this conguration, each pump is controlled by a

frequency converter. All pumps and frequency converters

must be of the same size.

3.24.2 Mixed Pump Conguration

This conguration combines some of the benets of the

master/slave conguration with some of the initial cost

savings of the xed speed conguration. Use this congu-

ration when the extra capacity of the xed pumps is rarely

needed.

The mixed pump conguration supports a mix of variable

speed pumps connected to the frequency converters with

extra xed speed pumps. The variable speed pumps are

staged on and destaged rst based on the frequency

converter speed. The xed speed pumps are then staged

on last and destaged last based on the feedback pressure.

Parameter Description Programming Guide

MG20OB02 Danfoss A/S © 05/2018 All rights reserved. 223

3 3

Loading...

Loading...