5 Troubleshooting

5.1 Status Messages

5.1.1 Warnings/Alarm Messages

A warning or an alarm is signaled by the relevant LED on

the front of the frequency converter and indicated by a

code on the display.

A warning remains active until its cause is no longer

present. Under certain circumstances, operation of the

motor may still continue. Warning messages may be

critical, but are not necessarily so.

An alarm trips the frequency converter. Reset alarms to

restart operation once their cause has been rectied.

This can be done in 3 ways

•

By pressing [Reset].

•

Via a digital input with the reset function.

•

Via serial communication/optional eldbus.

NOTICE

After a manual reset pressing [Reset], press [Auto On] to

restart the motor.

If an alarm cannot be reset, its cause may not have been

rectied, or the alarm is trip-locked (see also Table 5.1).

Alarms that are trip-locked

oer extra protection, meaning

that the mains supply must be switched o before the

alarm can be reset. After being switched back on, the

frequency converter is no longer blocked and may be reset

as described above once the cause has been rectied.

Alarms that are not trip-locked can also be reset using the

automatic reset function in parameter 14-20 Reset Mode.

NOTICE

Automatic wake-up is possible!

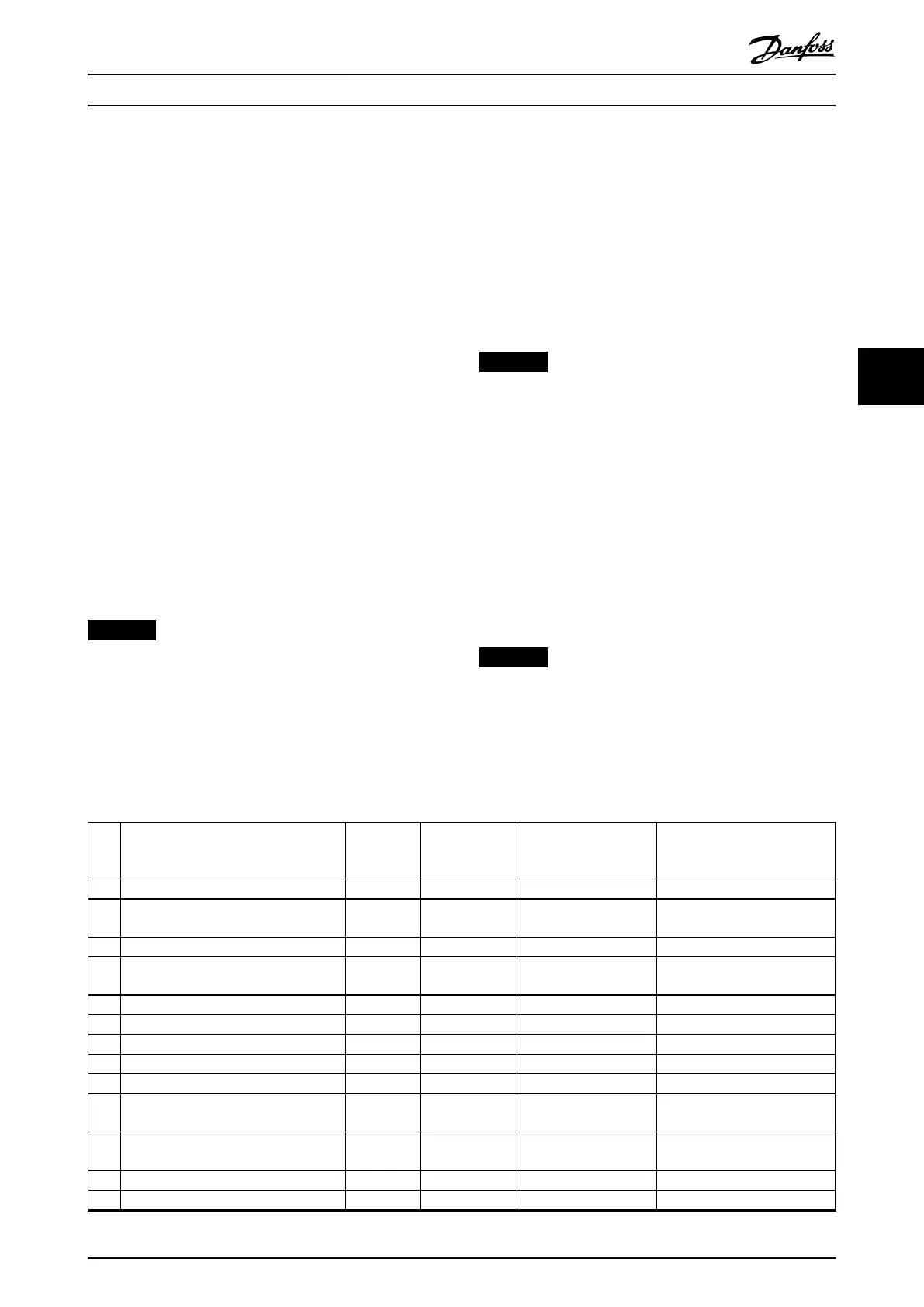

If a warning and alarm are marked against a code in

Table 5.1, this means that either a warning occurs before

an alarm, or else that it is possible to specify whether it is

a warning or an alarm that is to be shown for a given

fault.

This is possible, for instance, in parameter 1-90 Motor

Thermal Protection. After an alarm or trip, the motor carries

on coasting, and the alarm and warning ash. Once the

problem has been rectied, only the alarm continues

ashing until the frequency converter is reset.

NOTICE

No missing motor phase detection (numbers 30–32) and

no stall detection is active when parameter 1-10 Motor

Construction is set to [1] PM non-salient SPM.

Num

-

ber

Description Warning Alarm/Trip Alarm/Trip Lock Parameter

reference

1 10 volts low X – –

2 Live zero error (X) (X) – Parameter 6-01 Live Zero Timeout

Function

3 No motor (X) – – Parameter 1-80 Function at Stop

4 Mains phase loss (X) (X) (X) Parameter 14-12 Function at

Mains Imbalance

5 DC-link voltage high X – – –

6 DC-link voltage low X – – –

7 DC overvoltage X X – –

8 DC undervoltage X X – –

9 Inverter overloaded X X – –

10 Motor ETR overtemperature (X) (X) – Parameter 1-90 Motor Thermal

Protection

11 Motor thermistor overtemperature (X) (X) – Parameter 1-90 Motor Thermal

Protection

12 Torque limit X X – –

13 Overcurrent X X X –

Troubleshooting Programming Guide

MG20OB02 Danfoss A/S © 05/2018 All rights reserved. 283

5 5

Loading...

Loading...